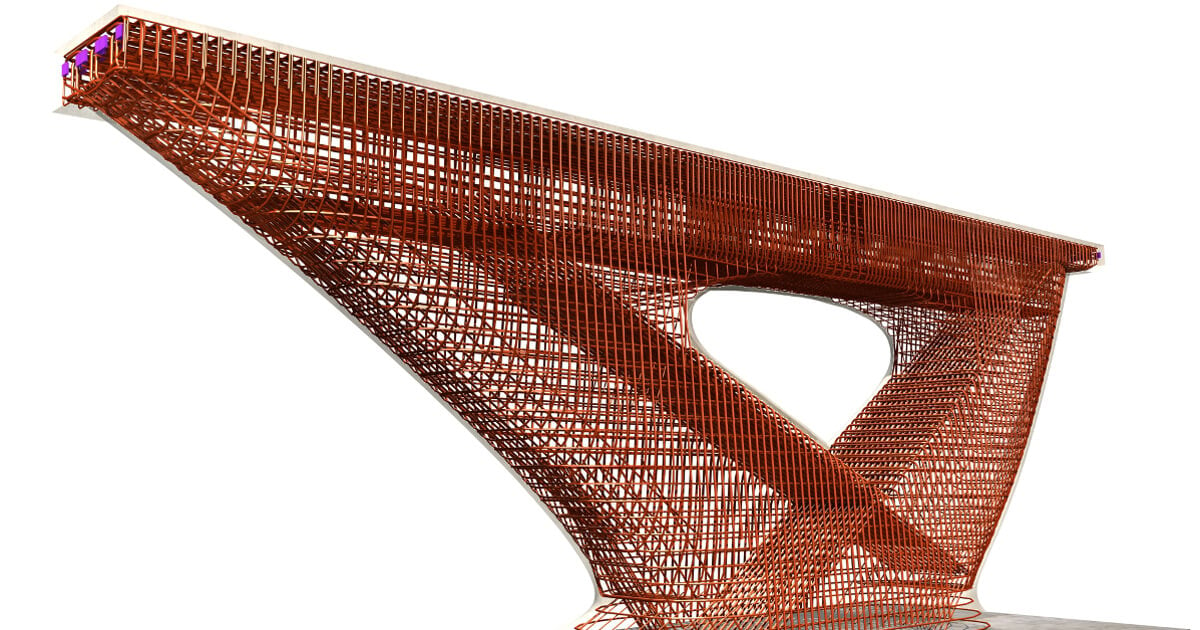

Moving from 2D to 3D rebar detailing with ALLPLAN offers a host of advantages for detailers, such as being able to visualize the completed rebar in 3D yet detail quickly using familiar 2D workflows. However, 3D rebar detailing also provides significant project and business benefits as well. Detailing rebar is only three-quarters of the job; visualization, document and drawing production, changes, and project management activities also take up considerable time. Whether the drafting is completed in-house or by a professional drafting firm, the slim margins often involved mean that staying competitive requires every advantage. Moving to 3D rebar detailing software can undoubtedly transform the rebar detailing process, but the real gains are the business benefits that arise as a result of time savings.

Win More Work

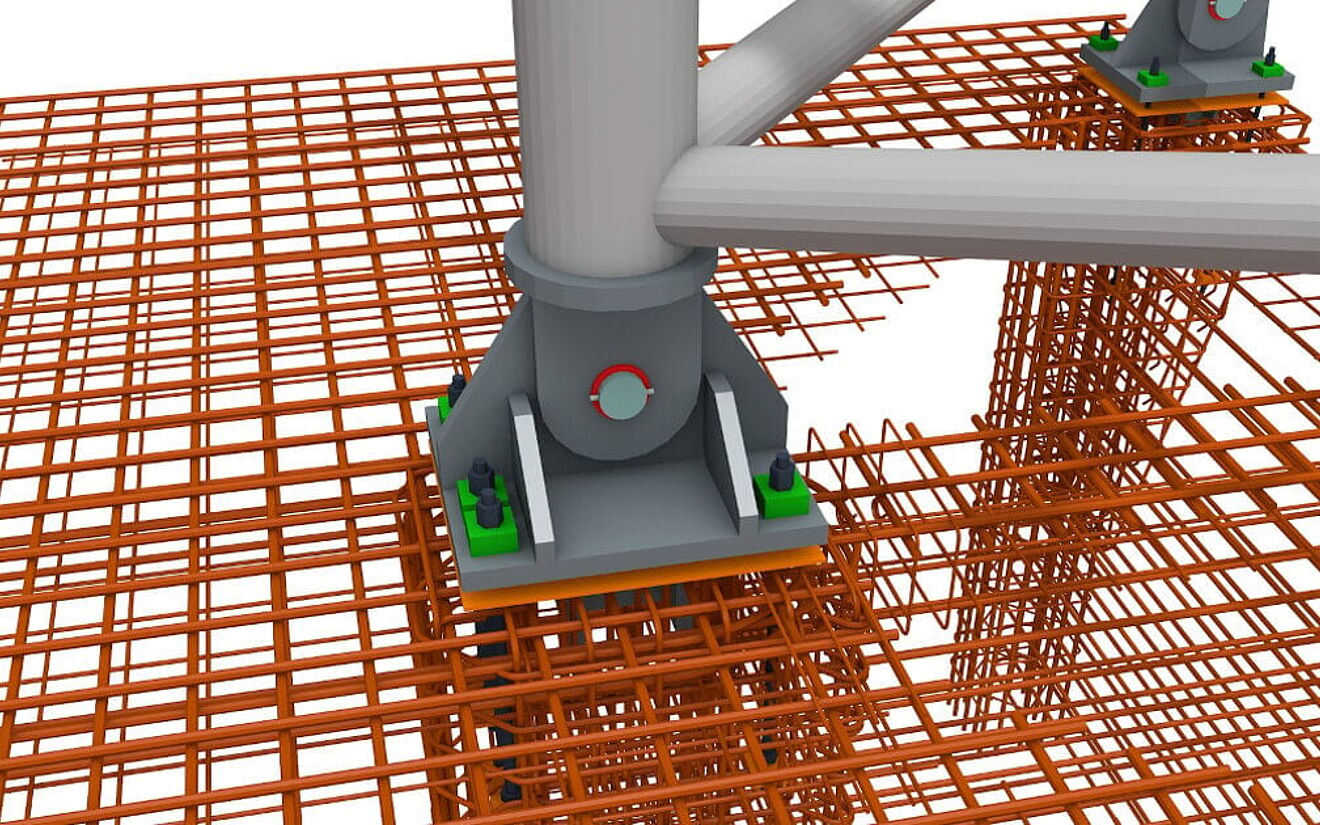

With 3D rebar detailing software, accuracy – and therefore quality – is greatly increased in comparison to 2D rebar CAD software. Because the information is derived from the 3D model, there is no need to manually count each item or re-draw each section or view and risk potential mistakes. Improved accuracy through automation means fewer errors, which in turn leads to less re-work and fewer wasted materials during production. The resulting increased quality also helps support a better reputation with contractors and engineers, potentially leading to more work.

Increase Throughput

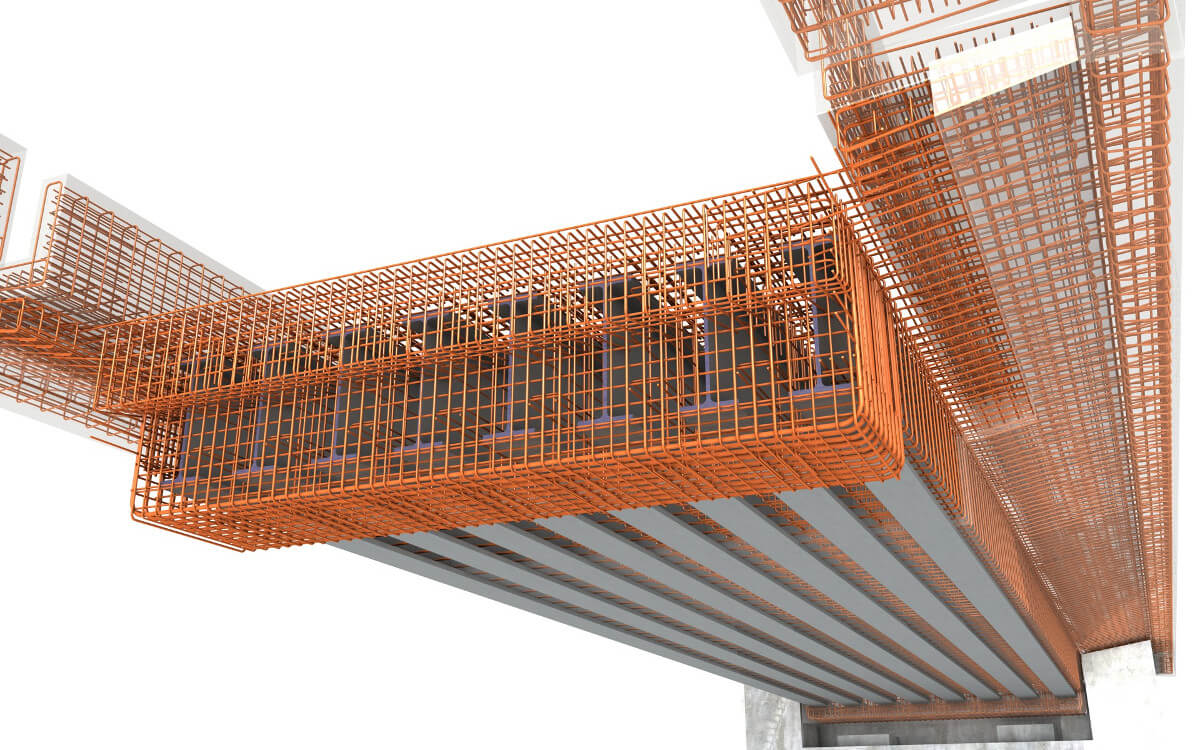

Reaching a complete set of rebar documentation faster frees up detailers to take on more projects in the same amount of time. Intelligent tools can quickly and automatically extract information from the 3D rebar model for reports such as bar bending schedules and quantities, or generate cross-sections and views in seconds. Drawing layouts can then be created in a fraction of the time, drastically increasing throughput. Accelerated documentation production means more projects can be accommodated, enabling a company to grow without the need to take on and train additional staff.

Protect Profit Margins

The automatic updating of the 3D rebar model and drawing layouts means that changes are less likely to derail a project and erode profit margins. With ALLPLAN, the 3D model is the source of all the information contained in drawings. When the model changes, views and sections update automatically without the need to be manually re-drawn, and reports can be re-generated and re-inserted into the layout in seconds – providing a considerable time saving compared to 2D methods. Clients are satisfied as their changes are accommodated and company profits remain protected.

Improve Competitiveness

Some engineering firms choose to outsource rebar detailing to offshore companies as they lack the in-house detailing manpower and/or skills; however, the effort required for coordination and quality assurance could be quite high. The higher productivity that ALLPLAN enables – up to 30% – can make outsourcing less attractive when domestic rebar detailing firms can provide a competitive service that is easier for clients to manage.

The Benefits of Working Smarter

3D rebar detailing software with smart, automated tools, facilitates improved precision, quality, productivity, and change management – enabling drafters to be more productive. Engineering and precast companies can therefore realize significant time savings and take on more work with the same staff as a result, providing an instant boost in profit margins. In addition, rebar detailing companies can increase their competitiveness by providing a high-quality service that other firms cannot. Working smarter with 3D rebar detailing software is therefore an essential component of staying competitive and profitable.