A typical rebar detailing office has a spread of different ages working there – from those with just a few years of experience, to staff who have been detailing rebar for decades. In many ways, this mirrors the architecture, engineering, and construction (AEC) industry itself. However, as experienced staff are so quick to produce rebar documentation, often existing ways of working remain in use long after they have been replaced with more efficient methods. After all, by using familiar workflows only new detailers require training, rather than a whole office. Yet 3D rebar detailing software provides more benefits than just quicker deliverables – the benefits to the business, as well as the entire workflow, are significant. With the right rebar CAD software, this does not have to involve a steep learning curve that staff are not ready for, either.

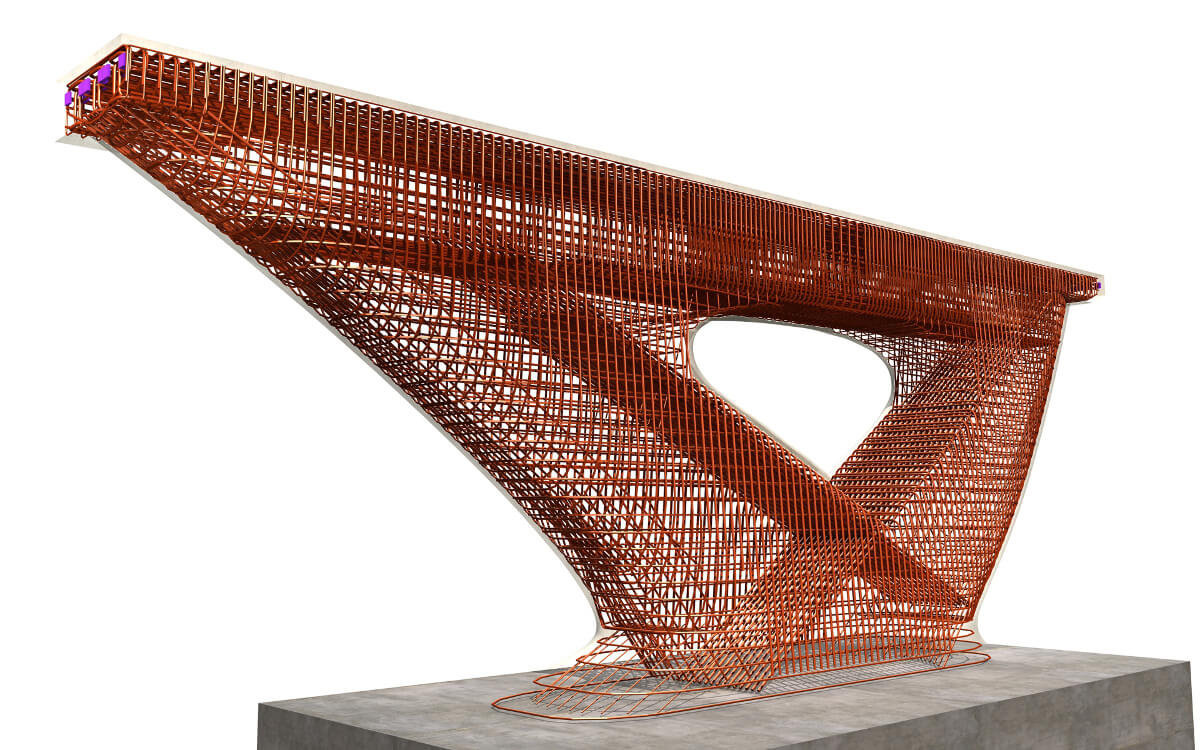

Familiar Workflows in 2D or 3D

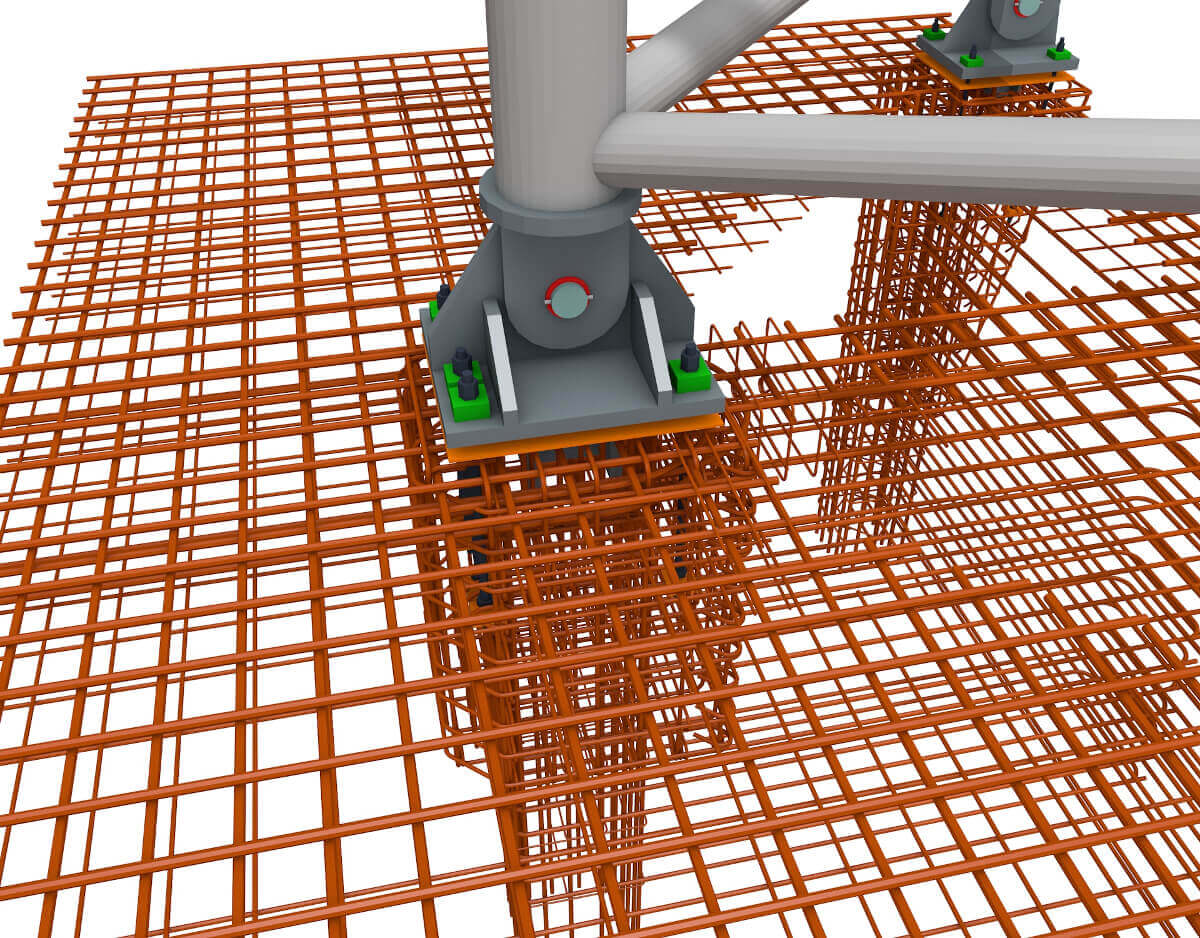

One of ALLPLAN’s unique benefits is the ability to work in either 2D or 3D, according to the user’s preference. Anything drawn in 2D has the 3D model generated automatically, and vice versa. This provides rebar detailers with the ultimate flexibility to work in the manner most comfortable to them, while still providing the benefits of 3D modeling. In an office where there may be a range of different approaches, this is particularly beneficial, as staff who want to work with newer, 3D methods can do so without forcing detailers who prefer a 2D workflow to use different rebar software.

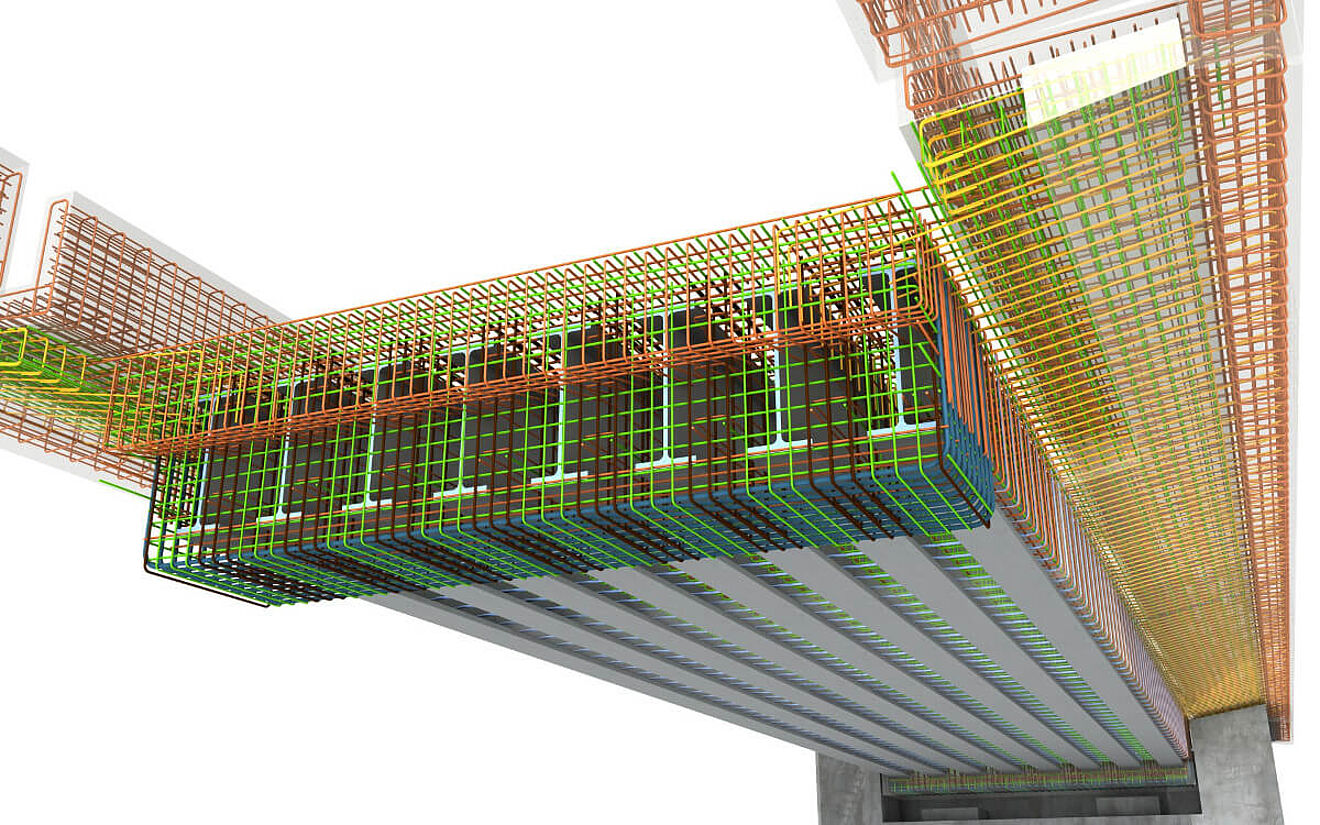

Rebar Detailing in One Place

ALLPLAN can achieve everything rebar detailers need in one package – there is no need for additional software, or even for outsourcing to a specialist reinforcement detailing company. The 2D to 3D approach mirrors the detailing process well; a cross-section can be extracted from the 3D model, reinforced and detailed in 2D, and then added to the drawing layout. However, unlike a purely 2D rebar package, the reinforcement can be checked for clashes thanks to the improved visualization in 3D and intelligent reporting tools. Accuracy is increased dramatically, without the need to make a giant leap into working in 3D completely and the added learning curve that this requires.

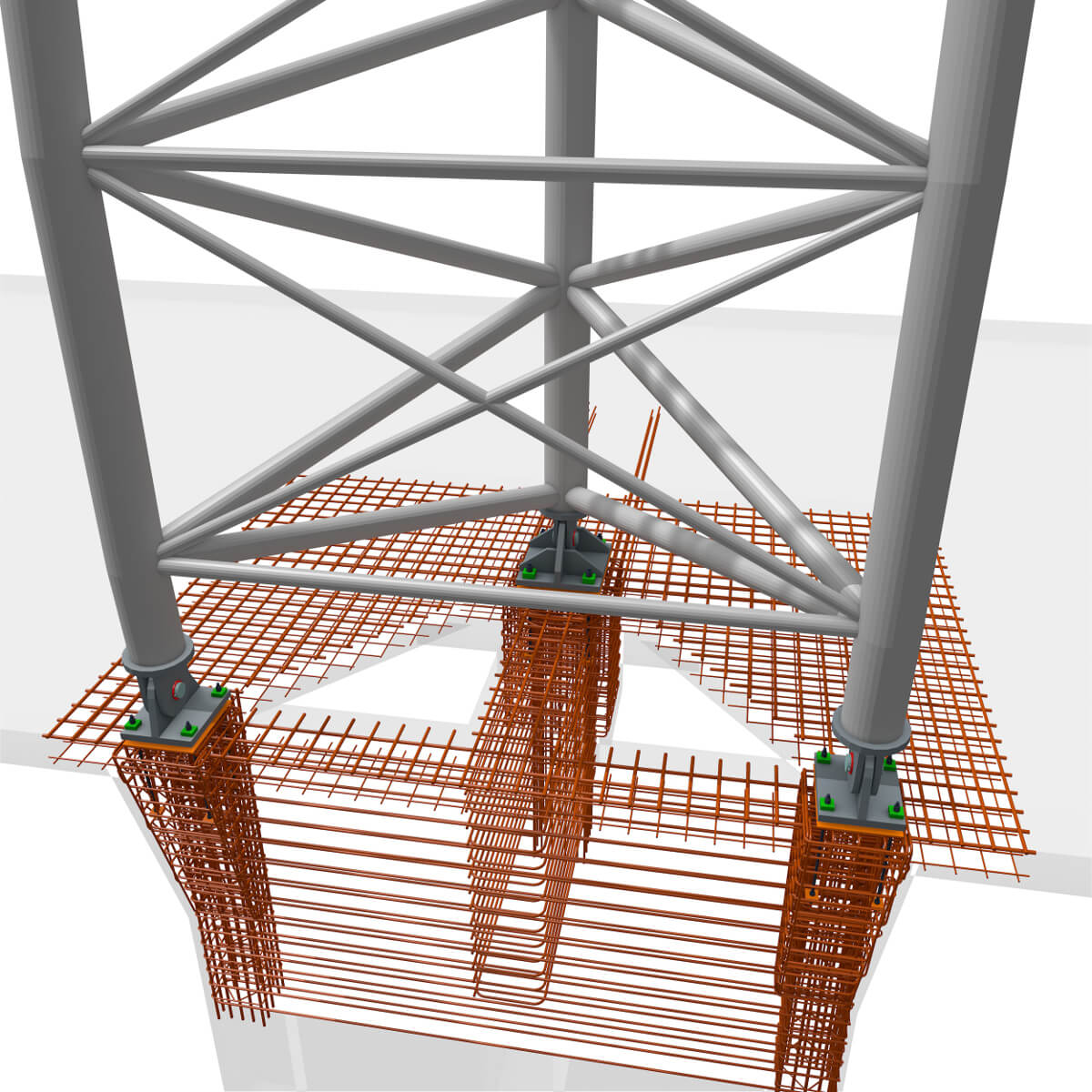

Reduce the Costs of Outsourcing

Costs can also be saved by removing the need to outsource detailing work, providing more control over the drawing production process for improved quality. While for some companies this was attractive as there were no rebar detailing skills in-house, it still required considerable effort for coordination and quality assurance. This effort is increased even more if an overseas detailing company was used. There is a trade-off to be made in terms of finding qualified rebar detailing staff or outsourcing the work – but with the productivity benefits of rebar detailing that ALLPLAN offers, outsourcing is much less attractive. Combined with the integrated structural analysis that can be done via Bimplus, there are significant benefits in comparison to using reinforcement sketches generated by static structural analysis tools.

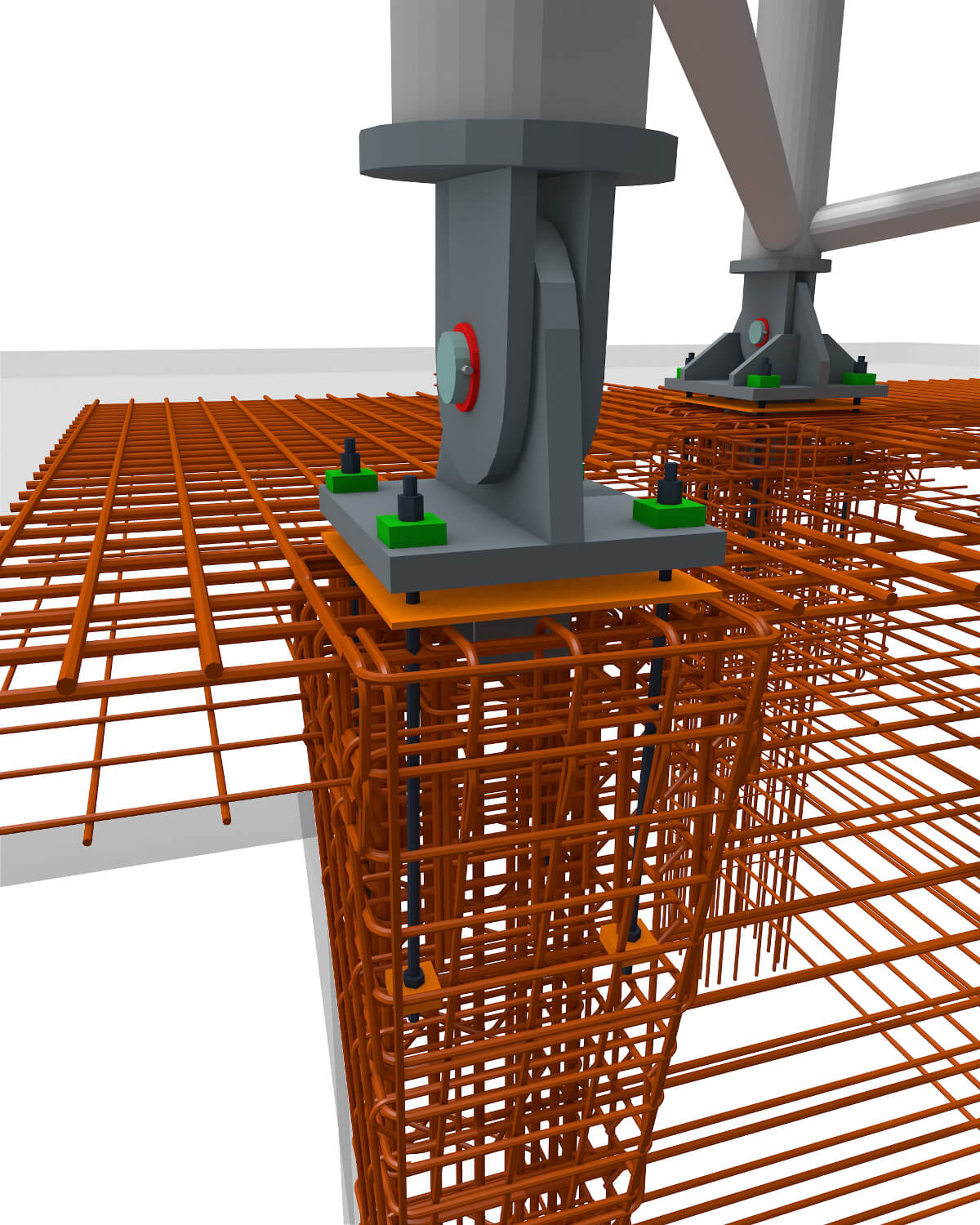

Better Bar Management

In-house rebar detailing offers considerable business benefits as well. Bar management is much easier as all the information is in one place – there is no need to spend 20 minutes looking for missing bar information in multiple sources. Data can be added to each bar in ALLPLAN using attributes, so that finding the required information is as easy as finding the bar in the model. In addition, using the bar attributes means that rebar detailing companies can leverage the powerful reporting features within ALLPLAN to quickly and easily create internal reports from the model in seconds.

Rebar Detailing Your Way

Using ALLPLAN for your rebar detailing provides significant business benefits, without forcing detailers to choose between 2D or 3D. Instead, ALLPLAN provides complete flexibility and total user freedom to work they way they want, while providing the benefits of both 2D and 3D approaches. The entire rebar process is transformed, while ensuring that quality, accuracy, and productivity remain high.