Steel has long been known for its strength and versatility, enabling the creation of structures that captivate and inspire. From the adrenaline-infused expanses of theme parks to the cutting-edge designs of cultural institutions, structural steel has played a pivotal role in bringing some of the world’s most unusual and recognizable projects to life.

Below, we take a look at six extraordinary steel projects, all of which have been fully or partly designed or detailed using the innovative solutions provided by SDS2, which is now part of the ALLPLAN family. As we explore these architectural marvels, we celebrate not only the material and the technology but also the ingenuity and vision that structural steel, sculpted by expert hands, can achieve.

Super Nintendo World, Universal Studios Plaza | Orlando, Florida, USA

Super Nintendo World at Universal Studios in Orlando, Florida, exemplifies cutting-edge steel detailing, having earned the Grand Prize in the SDS2 Solid Steel Awards 2023 in the Commercial, Small Tonnage category. Detailed by Ovation Services LLC using SDS2, this vibrant attraction features complex architectural elements such as curved perimeter framing, a waving bridge, and a circular floor platform designed to support animated figures of beloved video game characters.

The detailing challenges were increased by the requirement for connections on the circular floor, which necessitated a blend of SDS2’s automated capabilities and meticulous hand designs. Despite the complexities, the project is notable for its extremely accelerated timeline. The team was tasked to produce an advanced bill of materials (ABM) within 10-12 working days post-award, with all drawings successfully submitted for approval within a mere 13 weeks, showcasing the efficiency and precision enabled by SDS2 technology.

U.S. Olympic & Paralympic Museum | Colorado Springs, Colorado, USA

The United States Olympic & Paralympic Museum in Colorado Springs, Colorado, has been described as a showcase of steel solutions, winning the 2022 AISC MERIT Award in the $15m to $75m category. This architectural icon, characterized by its dynamic use of steel, features a facade of 9,000 diamond-shaped panels that evoke the motion and spirit of the Olympic Games.

The structure’s complex design was made possible through the early and continuous involvement of steel detailers, fabricators, and erectors. This included KL&A Engineers and Builders, who played a dual role as both structural engineers and steel detailers using SDS2. Their participation from the schematic design phase through to construction documents facilitated the precise coordination of load placements and swift resolution of complex challenges, including the realignment of a misaligned concrete core. This collaborative approach, crucial for managing the building’s innovative geometry and structural demands, epitomizes the teamwork and dedication celebrated at the museum itself.

One Times Square | New York City, New York, USA

One Times Square, the iconic site of New York’s New Year’s Eve ball drop, is undergoing a transformative $500-million renovation to become a modern tourist attraction. This project, which was recognized in the 2023 SDS2 Solid Steel Awards, involves a significant integration of new steel into the building’s original 1903 structure. This was handled with precision by Kennebec Valley Detailers and Orange County Ironworks.

Despite challenges like outdated structural designs and the building’s unique wedge shape, the use of SDS2 and BIM technologies has been crucial. These tools facilitated complex detailing and logistical planning, especially for the new viewing deck featuring innovative glass and steel designs. The project emphasizes teamwork and technological innovation, preserving the historical integrity of One Times Square while incorporating cutting-edge design elements. This renovation sets a new standard for blending historic preservation with modern construction techniques, showcasing an innovative blend of the past and the future.

Deloitte Summit Tower | Vancouver, British Columbia, Canada

The Deloitte Summit Tower, a unique architectural feat developed by Westbank and Allied, stands out with its stacked-cube design. It rises 24 stories and features a glass facade accented by vertical green spaces. This project, awarded the 2020 Solid Steel Competition Grand Prize in the Commercial, Large Tonnage category, was expertly managed by Supermétal Structures, now a subsidiary of Canam Group Inc.

Using SDS2 software for seamless coordination, Supermétal not only fabricated but also designed, detailed, and erected the building’s intricate steel structure. The building’s challenging geometry, with cubes meeting at varied angles, required innovative connection designs and meticulous sequencing. Supermétal’s engineers leveraged SDS2’s 3D modeling to ensure precision and efficiency, particularly for the non-standard transitions between the steel and concrete elements.

Whiting Forest of Dow Gardens Canopy Walk | Midland, Michigan, USA

Designed by Adco Detailing and winner of the 2020 SDS2 Solid Steel Awards in the Commercial, Small Tonnage category, this project is an unusual yet brilliant use of steel. Stretching 1,400 feet and elevated up to 40 feet above the ground, this canopy walk is the longest in the nation. Its construction required 2,720 tons of steel and 2,890 bolts, with almost every piece being nonstandard due to the walkway’s curvy and undulating design.

Adco Detailing faced numerous challenges, from incorporating spiraled handrails at irregular angles to designing around existing trees, minimizing environmental impact. SDS2 software played a crucial role in managing these complexities, providing detailed 3D modeling that facilitated communication and ensured precision throughout the construction process. This project not only showcases the capabilities of steel in custom designs but also highlights sustainable construction practices within a forest setting.

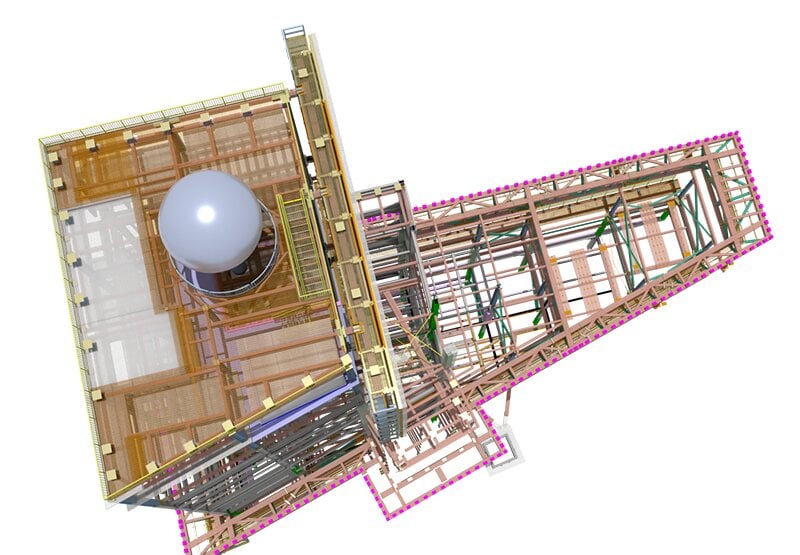

NASA Mobile Launcher 2 | Kennedy Space Center, Florida, USA

NASA’s Mobile Launcher 2 (ML2) at Kennedy Space Center, Florida, is a major advancement in the United States’ space exploration efforts, particularly for the Artemis missions aimed at lunar exploration. Designed to support the Space Launch System (SLS) Block 1B and Block 2 rockets, ML2 is a robust, 355-foot-tall launch platform capable of handling the substantial 11.3-million-pound structure and the additional forces of taller, more powerful rockets.

Integral to ML2’s functionality are multiple swing arms providing critical support systems like power, data, and propellant delivery, all managed remotely from NASA’s Launch Control Center. The platform’s design incorporates significant lessons from its predecessor, ML1, optimizing it for the increased demands of future lunar missions. Constructed by Bechtel National, Inc., and fabricated in part by SDS2 customer, PVS Structures, ML2 is a testament to the intricate engineering required to return humans to the Moon and beyond.

Conclusion

These diverse projects, from the animated expanses of Super Nintendo World to the cutting-edge launch platform of NASA’s Mobile Launcher 2, illustrate the remarkable capabilities of steel in transforming our built environment. Each structure, detailed with precision and ingenuity, not only showcases the versatility of SDS2 but also highlights the boundless possibilities when innovative technology meets visionary engineering.