Stadiums (or sports arenas) are unique architectural masterpieces. Yet stadium design is a careful balance of achieving the right vision for the arena while still ensuring that spectators will have an excellent view and enjoyable experience. Accommodating the flow of tens of thousands of visitors – not to mention designing all the services they will require, as well as those athletes and staff who will use the arena – takes time, dedication, and the right stadium design software, such as ALLPLAN. Here are the top five stadiums that have been designed and built using ALLPLAN.

Košice Soccer Stadium, Slovakia

At the end of 2018, construction began on a new soccer stadium in Košice, Slovakia that can hold 12,685 spectators. Featuring a heated playing field, there were also training areas, changing rooms, and other facilities that would ensure the stadium met UEFA standards and could host international soccer matches. The nearby Košice-Barca airport runway meant that there were stringent height restrictions for the new stadium; however, the designers were able to create a striking structure despite this. The disk-shaped stadium is enveloped in a perforated sheath that floats around the concrete and steel structure. At night, the perforations allow light through to create a different appearance.

The height limitations meant a 3D model was imperative to ensure accuracy. Building Information Modeling (BIM) was also required by the client for this project. Accordingly, the designers chose ALLPLAN to create the spatial model and fulfill their BIM duties. This helped them to identify and rectify any collisions between stadium elements prior to construction, and also helped facilitate communication and collaboration during the project. The model was shared with the project stakeholders using ALLPLAN’s Bimplus portal, as well as using the IFC format.

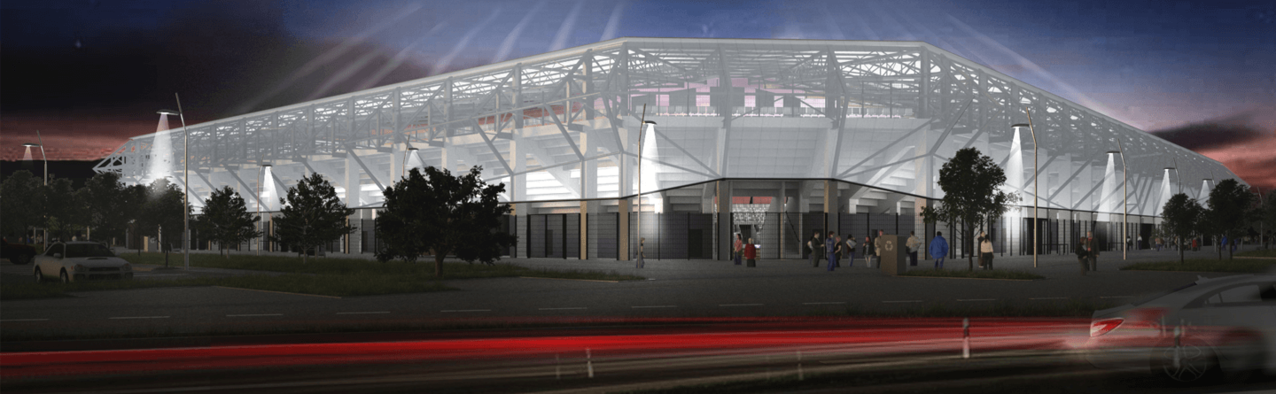

Wildpark Stadium, Germany

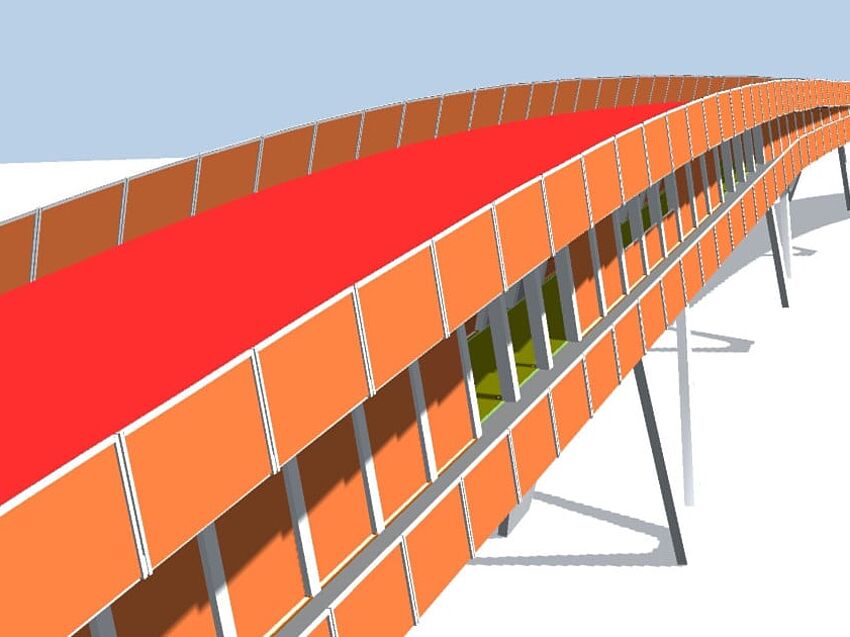

The new Wildpark Stadium in Karlsruhe, Germany will boast 34,000 seats within its rectangular walls. However, the construction had to be planned so that the old stadium could be dismantled simultaneously, while still providing seating for 15,000 visitors at any one time. Planning such a complex operation requires the utmost accuracy, so 3D modeling and BIM were an enormous help on the project. The grandstand area in particular had many details that needed to be meticulously planned, which otherwise would have been difficult to do with precision using 2D drawings. The unconventional Y-shaped structural roof supports were also a challenge on this project. Using BIM meant that the data could be used to create various plans and calculations and information exchanged easily with other stakeholders.

ALLPLAN greatly facilitated the design of the roof structure, as well as the construction planning. The 3D visualizations enabled the structural engineers to see how far the roof supports deviated from each other so they could then devise a feasible solution that still fulfilled the architect’s vision. The initial construction started with the simple supports, which proved that the details developed with ALLPLAN fit reliably on site.

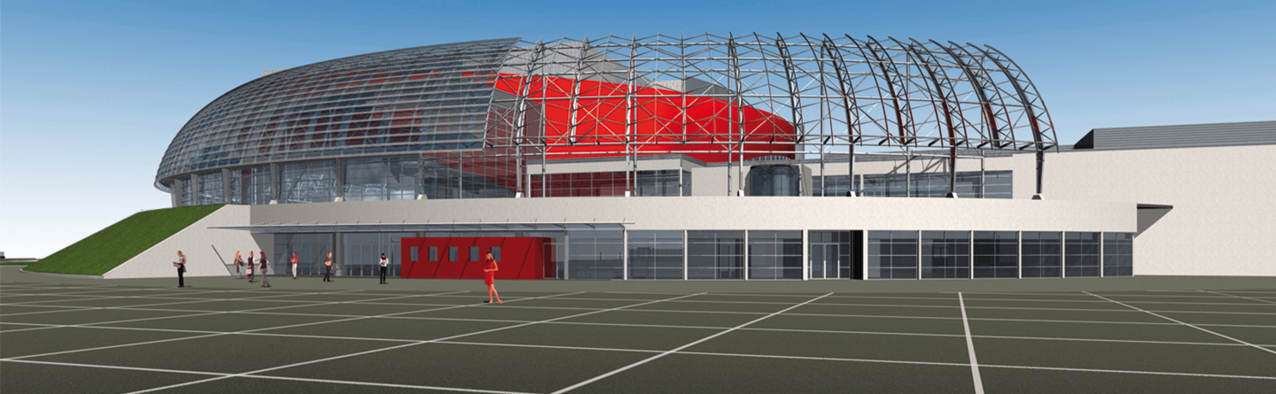

Le Phare Arena, France

Translated as “lighthouse”, Le Phare Arena in Chambéry, France will be able to be seen from miles away. Seating up to 6,000 people, this unique arena is designed to be a truly multi-purpose building, adapting its functions to host a wide range of events. The exterior features a domed glazed façade over a complex network of steel girders.

The integration of several disciplines that could be achieved with ALLPLAN was a key contributor to the success of this project. After initially creating a building model draft and creating an animated visualization of the interior using CINEMA 4D – which won the project for the architect – the steel components were transferred to ALLPLAN, where they could be used as intelligent 3D elements. The building services were also integrated into the digital building model, so that everyone was using the same model and data. The HVAC designers had the assurance of using the correct information, and the architects could plan space for the building services. The building data in ALLPLAN was also used to evaluate and optimize the thermal behavior of the arena.

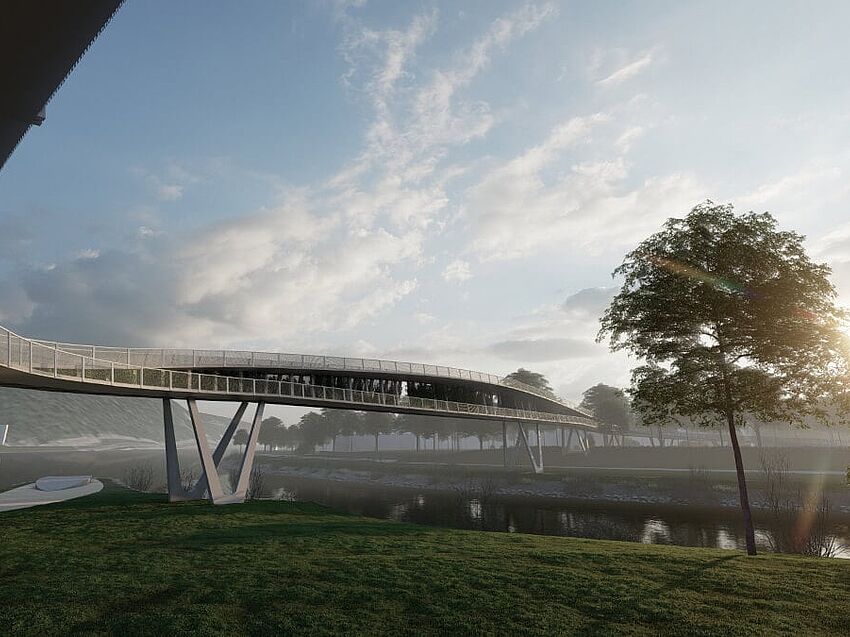

Park Malšovice Arena, Czech Republic

Another multifunctional building, the Park Malšovice Arena is designed to accommodate not just a football pitch, but other sports and social events year-round. In addition to the facilities required for football, there is also an athletics hall, restaurant, business and shopping centre, and gymnasium located on the site. The supporting structure of the stands is designed as a reinforced concrete skeleton, which uses precast concrete elements, while the roof is made from steel trusses.

ALLPLAN and SCIA Engineer were used due to the large and complex nature of the project. Having intelligent 3D models for both the stadium and shopping center paid off, particularly at the outset when several variants needed to be designed and presented to the investor. Without the 3D models and unique tools in ALLPLAN, the designer would not have been able to achieve the desired quality in the given timeframe. The two civil engineering design software programs worked hand-in-hand, allowing the structural design model in ALLPLAN to be seamlessly transferred to SCIA Engineer for further structural analysis and design. Once completed, this was transferred back into ALLPLAN where drawings could be created automatically and bills of quantities could be swiftly derived from the model, saving the designer valuable time.

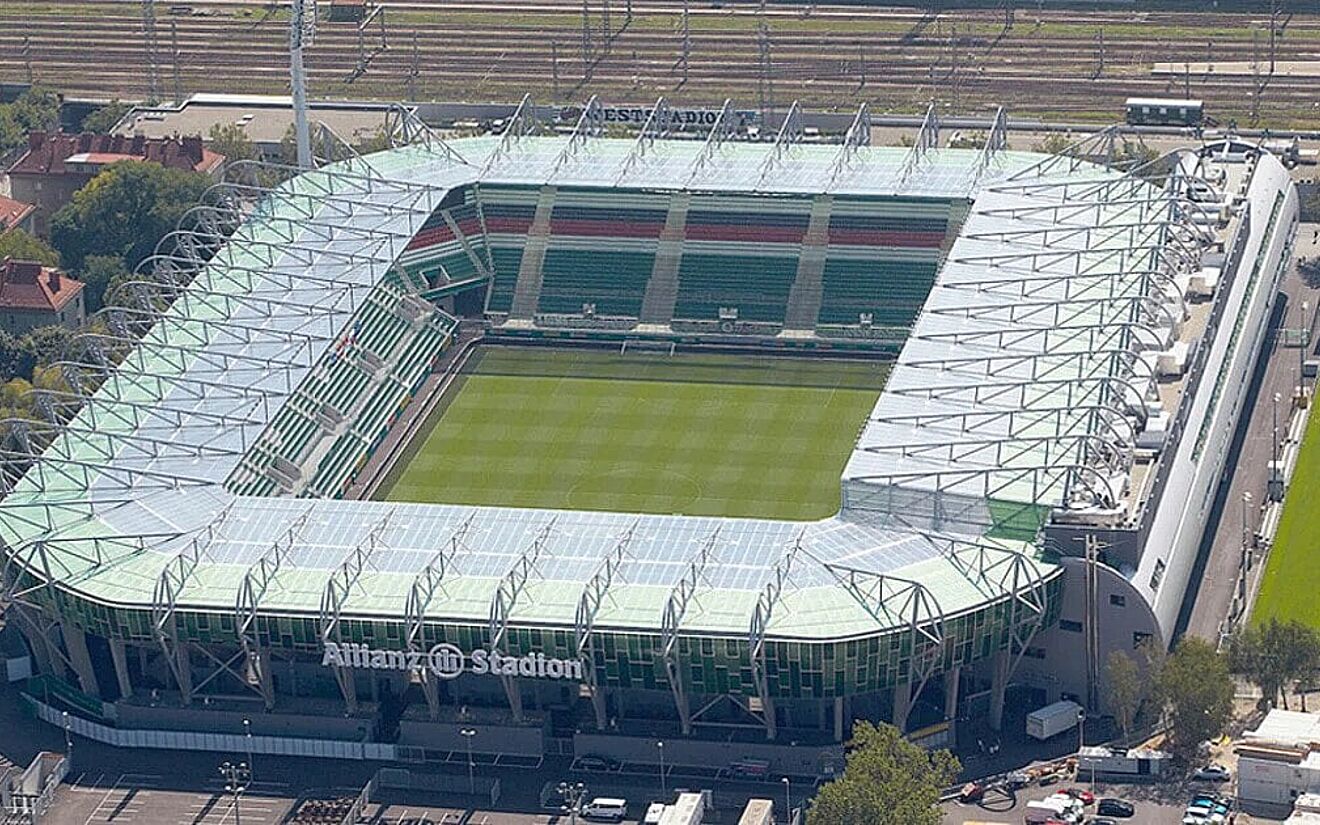

Allianz Stadion, Austria

Build in just 17 months, this soccer stadium in Vienna, Austria is a prime example of the efficiency of precast construction. Around 880 precast elements were required for the stadium, with 150 staircases and external columns that were 18 meters high and weighed over 40 tons.

For this project, the designer chose to model all the precast parts, girders, grandstand slabs, and hollow core walls in 3D to easily visualize the complex geometries. This also allowed the designer to plan for all the important openings in the precast elements, as well as the assembly requirements. The model could then be easily checked for any clashes between components, which was particularly useful due to the complex HVAC installation. The precise planning of this project resulted in reduced energy consumption on site thanks to the precast components, as well as a reduction of 90% in terms of waste compared to traditional methods.