ALLPLAN Bridge is Now ALLPLAN Civil: What the Name Change Means for Users

Navigating the complex terrain of modern bridge design demands more than just engineering expertise; it calls for cutting-edge solutions that streamline workflow, foster collaboration, and enhance data interoperability. For Yüksel Proje's recent Shusha Bridge project in Azerbaijan, ALLPLAN Bridge was a game-changing tool that was integral to delivering just that. This ambitious undertaking grappled with a multitude of challenges, from intricate geometries to rigorous alignment restrictions, and emerged with a bridge design that's as innovative as it is beautiful. Keep reading to see how Yüksel Proje leveraged parametric modeling, workflow automation, visualizations, and more to achieve a breathtaking combination of form and function in the Shusha Bridge.

Accuracy with technology

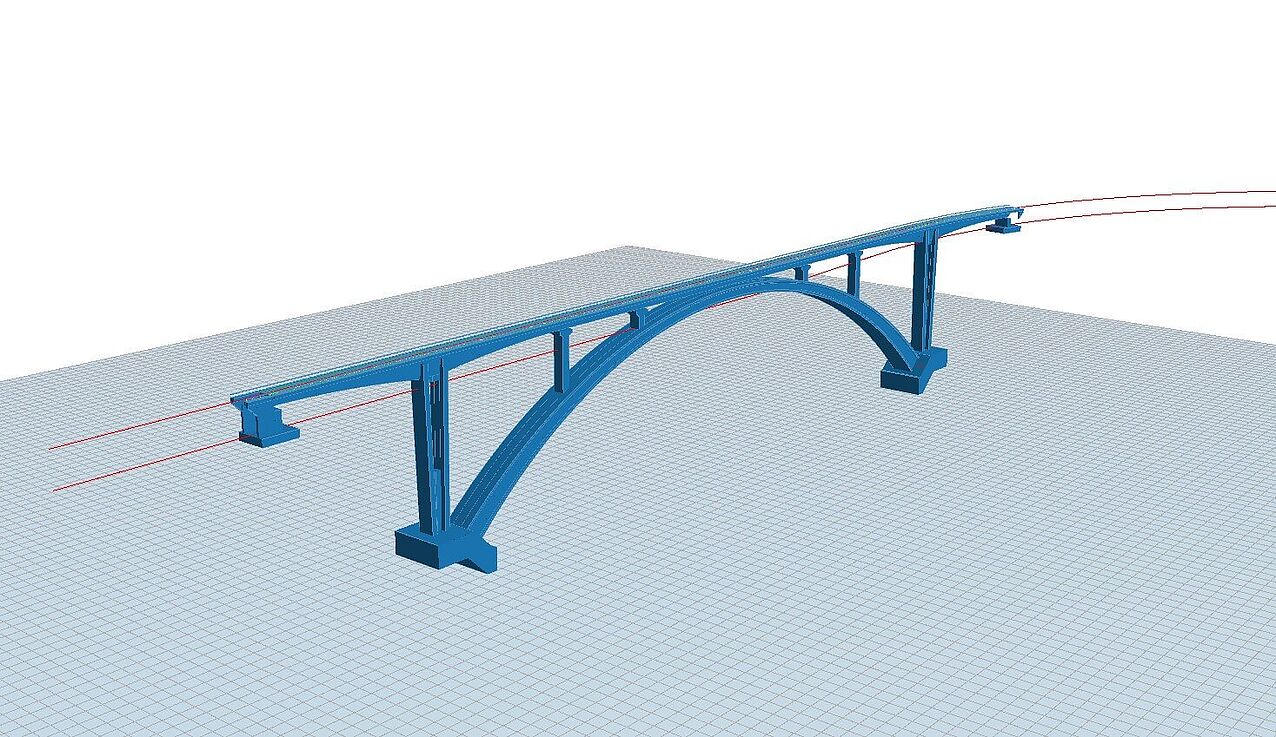

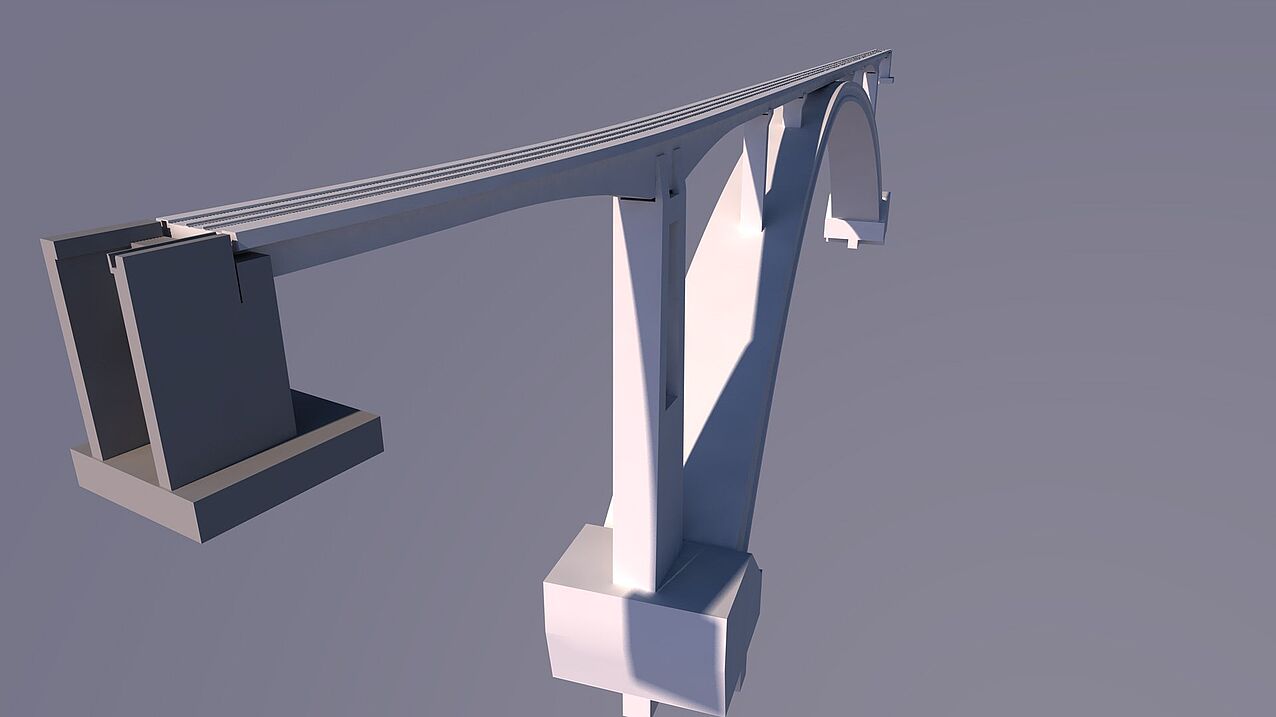

The bridge, designed to cross a deep valley near Shusha, is as much a triumph of aesthetics as it is of engineering. To avoid high piers in the valley, a unique arch bridge layout was chosen. While visually stunning, this design choice presented several challenges, including the need for detailed geometric parameters and specialized construction methods. That's where ALLPLAN Bridge's partial import and export functionality was particularly beneficial. By employing its TCL command language format, Yüksel Proje was able to partially export and import data, thus eliminating redundant tasks and avoiding errors in the geometric model.

Making reinforcement modeling easy

Another significant advantage of using ALLPLAN Bridge was its parametric reinforcement modeling capabilities. With PythonParts – which are objects created with Python code integrated with ALLPLAN's API – the engineers could create custom objects and automate tasks. The software enabled them to easily adjust reinforcement objects, catering to the bridge's varying pier heights.

This parametric approach was particularly advantageous for the project’s complex geometry, as it facilitated rapid adjustments to the reinforcement layout in response to design changes or construction challenges. With PythonParts linking directly to the geometric model, any alterations in the structure were automatically reflected in the reinforcement elements, ensuring both accuracy and consistency in the BIM workflow.

A picture is worth 1,000 words

Visualization was particularly beneficial on this project. These capabilities enabled real-time 3D rendering of complex geometries, facilitating easier communication and decision-making among project stakeholders. The intuitive interface and visual aids offered by ALLPLAN Bridge also helped to validate design choices at various stages, from conceptualization to final approval. High-quality visual outputs ensured that both technical and non-technical team members could understand the intricacies of the design, thereby streamlining the approval processes and reducing the risk of costly revisions.

Seamless sharing

Interoperability is one of the major pillars of modern construction projects, as they inevitably involve multi-disciplinary coordination between architects, engineers, and contractors. Here, ALLPLAN Bridge’s functionalities extended beyond just modeling and automation, offering robust solutions for data exchange and interoperability as well. The software's compatibility with Industry Foundation Classes (IFC) attributes ensured that data could be seamlessly shared across various software platforms and project stakeholders, enabling different disciplines to use the software of their choice. This is a business advantage as well as a technical one, as it facilitates quicker decision-making and adherence to project timelines.

Furthermore, by enabling outright assignment of IFC attributes, the software provided a streamlined framework for collaborative data management. This means that changes in design, materials, or schedules could be communicated instantly, avoiding bottlenecks and ensuring that all team members are working with the most current and accurate information. The enhanced interoperability functions not only streamlined the workflow but also minimized the chances of costly errors or delays, thereby contributing to both the efficiency and effectiveness of the construction process.

Conclusion

By leveraging ALLPLAN Bridge's multi-faceted functionalities, Yüksel Proje was able to overcome the design and construction demands of the Shusha Bridge project, all whilst demonstrating a forward-thinking approach to BIM in bridge construction.

If you're seeking a robust bridge design solution that offers both flexibility and precision, consider taking the next step in optimizing your design and construction workflows. Don't just take our word for it – experience the power of ALLPLAN Bridge firsthand by downloading a free, 14-day trial today.