Better Precast Girder Bridge Design with ALLPLAN: A Complete Workflow Solution

When the Tamina Bridge in the Swiss Alps was first proposed, the engineers were uncertain how they would create a bridge that spanned two different heights at each end of the valley, at a height of 220m (772 feet) above ground. Yet despite these challenges, the bridge was completed a year ahead of schedule in just four years – mainly due to the efficiencies that Building Information Modelling (BIM) provided. While the name may inadvertently imply that only buildings can benefit, BIM offers a host of advantages when designing and building bridges as well.

Interdisciplinary Coordination

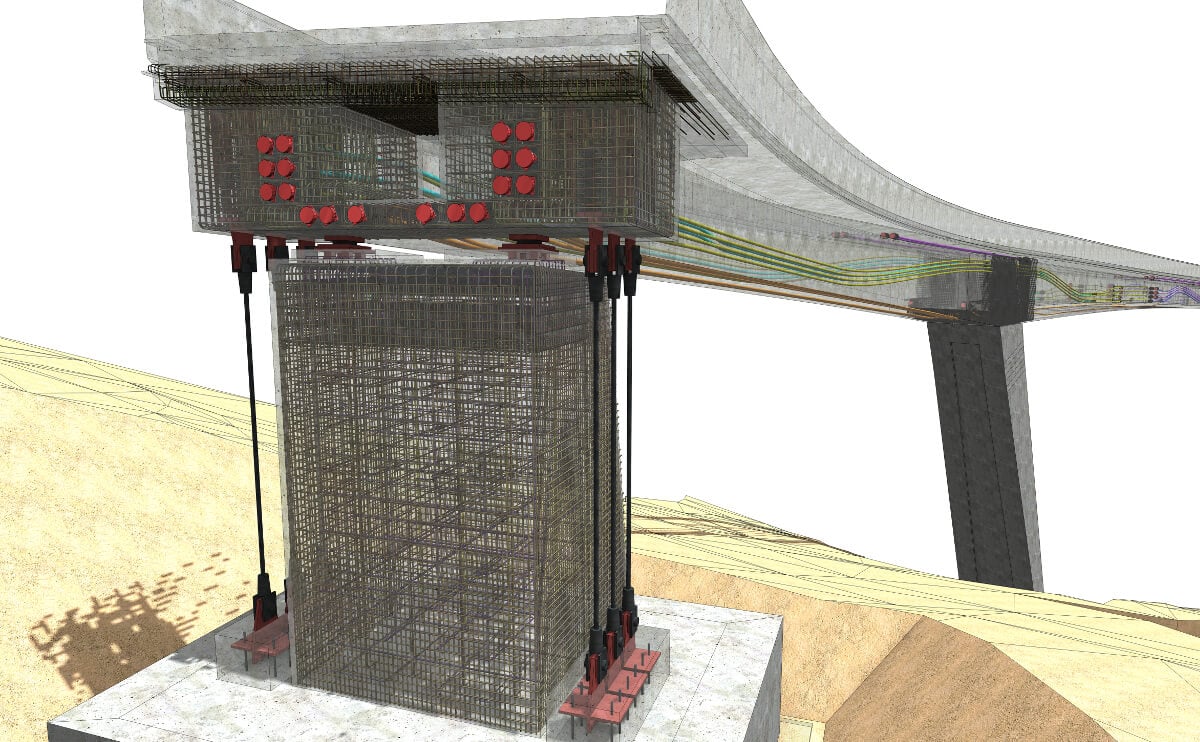

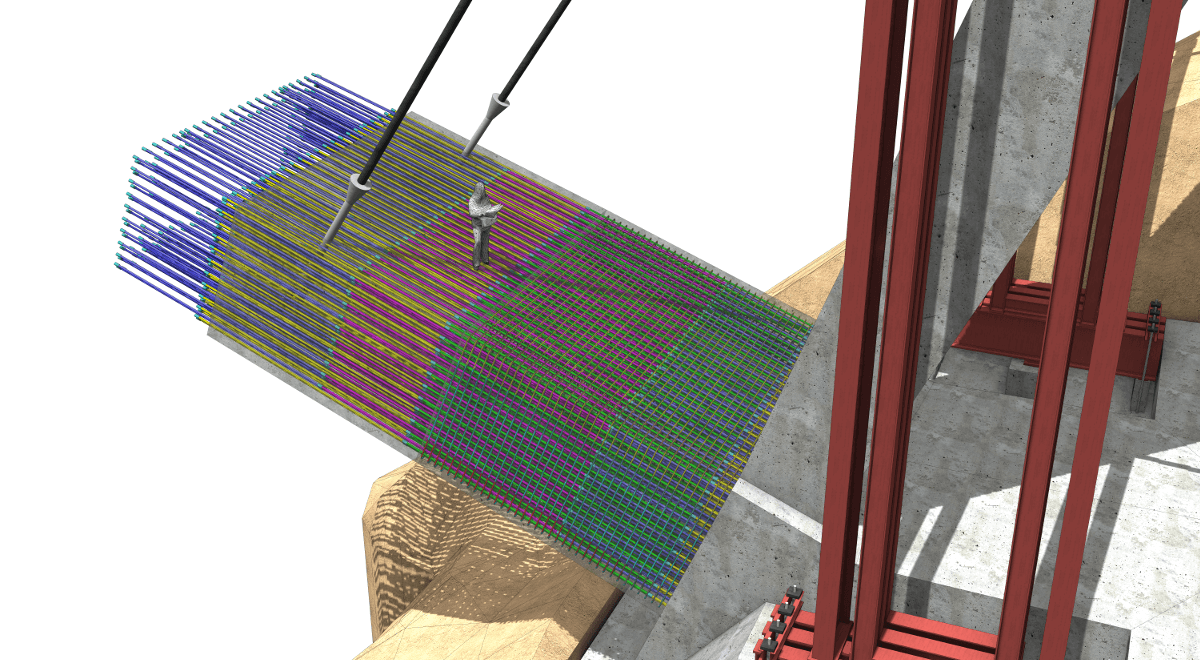

On a bridge project, there are many different specialists involved – such as the highway engineer, bridge engineer, structural detailer, and geotechnical specialists. Each requires a different set of information to do their job, yet at the same time, they also need to ensure their models and documents describe the same project. With a data management platform like Bimplus, the uploaded models can be easily combined so that clashes and inconsistencies can be quickly detected. Any issues can then be discussed and resolved with the other disciplines swiftly, with everyone working from the same set of information. In contrast, with a bridge designed in 2D CAD, any collisions might not be discovered until the work begins, leading to extra costs and time delays, as well as wasted materials.

Constructability Reviews

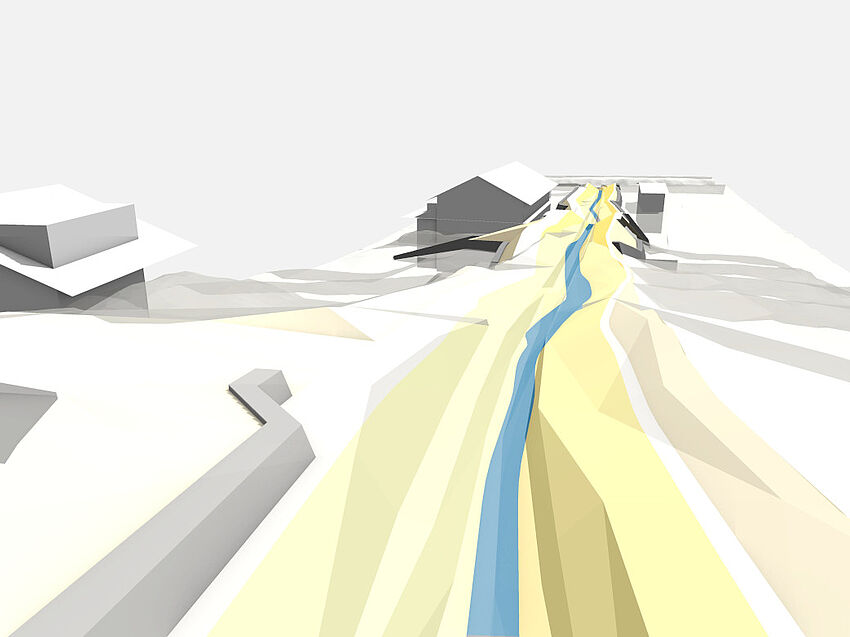

Determining if the bridge is feasible to be built can be made easier with the help of 3D bridge design software designed for this purpose. Using a federated model – a model that combines the individual sub-models of each discipline into a single, connected whole – the built-in rules of the bridge modeling software can help verify that the bridge meets codes and regulations in a fraction of the time compared to manual checks. In addition, the disruption from the construction phase and the final appearance of the bridge in-situ can be evaluated using BIM and 3D modeling, which can be important if the bridge is located in a densely populated or sensitive area.

Cost Optimization

Improving collaboration and coordination to design out errors and inconsistencies can help save the costs of re-work, both in the design office and on site. Avoiding defects during construction means there are no costs incurred from changing the design, which can happen if the owner runs over budget and is looking to cut costs in other areas. Any delays caused by changes or re-work can push the construction schedule into winter and periods of unpredictable weather, causing even more delays or potentially meaning that different codes and standards must be adhered to. The ripple effect of small changes from design errors can quickly mean that projects get out of control – but with BIM, the risk of this is drastically reduced.

The Future of Bridge Construction

BIM enables a three-dimensional bridge model to be used for communication, collaboration, simulation, and optimization. It can be used to develop accurate cost estimates, undertake structural analysis, and predict construction schedules, all whilst enabling coordination with all stakeholders. Even the operational phase can be enhanced with the use of the BIM model. In 20 years, no one will be able to imagine how construction projects could have been done in our time without BIM. To see the powerful features of BIM for bridges, download a free, 30-day trial of ALLPLAN or download our whitepaper "The Efficiency of BIM for Bridges".