ALLPLAN 2025-1: Smarter Workflows and Stronger Collaboration

Since 2022, the ‘SuperHub’ has enriched the centre of Meerstad: a future-proof and sustainably planned multifunctional building. In an iterative process, the structural engineers from Pieters Bouwtechniek succeeded in realising the planned aesthetics of the visible timber construction while ensuring stability. The structural engineers relied on SCIA Engineer software for the modelling and structural analysis of the load-bearing structure.

In Meerstad, the green lung on the eastern outskirts of the Dutch city of Groningen, a neighbourhood with around 5,000 new homes is set to gradually grow over the next decade. Inviting green spaces and open areas as well as the recreational lake Woldmeer create excellent conditions for the development of the neighbourhood. However, the planned city, which was designed on a drawing board, has so far lacked a community centre as a social meeting point with shopping facilities. The construction of the multifunctional ‘SuperHub’ building, which currently houses a supermarket, a café and a health centre, has now provided a remedy in the search for an urban centre. Thanks to the prefabrication of all parts of the building, the ‘SuperHub’ was completed after a short construction period in 2022.

Timber as a central design element

The visible timber supporting structure was designed by the Dutch architectural firm De Zwarte Hond. The spacious market hall, which looks like a cathedral with its large span and nine metre high ceilings, extends over a gross floor area of 2,090 square metres. The timber columns, arranged in a grid, are lined all around with a building-high, non-load-bearing curtain wall made of glass and steel, which features curved windows at the rounded corners of the oval building, provides thermal insulation to passive house standards and ensures particularly bright interiors. The timber construction has a positive climate footprint and was planned to be future-proof and sustainable. The large span and high ceilings allow for flexible, resource-saving building conversion and fulfil the requirements of changing usage needs. The large roof area offers sufficient space for greenery and a photovoltaic system. Thanks to the built-in air treatment system and heat and cold storage in the floor, a pleasant and energy-efficient indoor climate is also ensured.

22 glued laminated timber pillars support the flat roof

The nine metre high flat roof construction consists of a diagonal grid of glued laminated timber beams. The roof overhangs by 5.4 metres on all sides. It is supported by 22 pillars arranged in a grid of 10.8 metres x 10.8 metres. The geometry of the pillars is reminiscent of a tree: each pillar is made up of four curved glued laminated timber supports that branch out at the top to form a cross. The glued laminated timber supports are held together at the connections by invisible steel connecting elements. Beams extend from the end of each curved ‘tree’ support, forming the lattice-like structure of the symmetrical roof. The supporting structure is made entirely of hydrothermally modified hardwood. Both the beams and the columns have a cross-section of 200 x 600 mm². The length of the timber elements was limited to 15 metres to ensure that they could be easily transported and assembled.

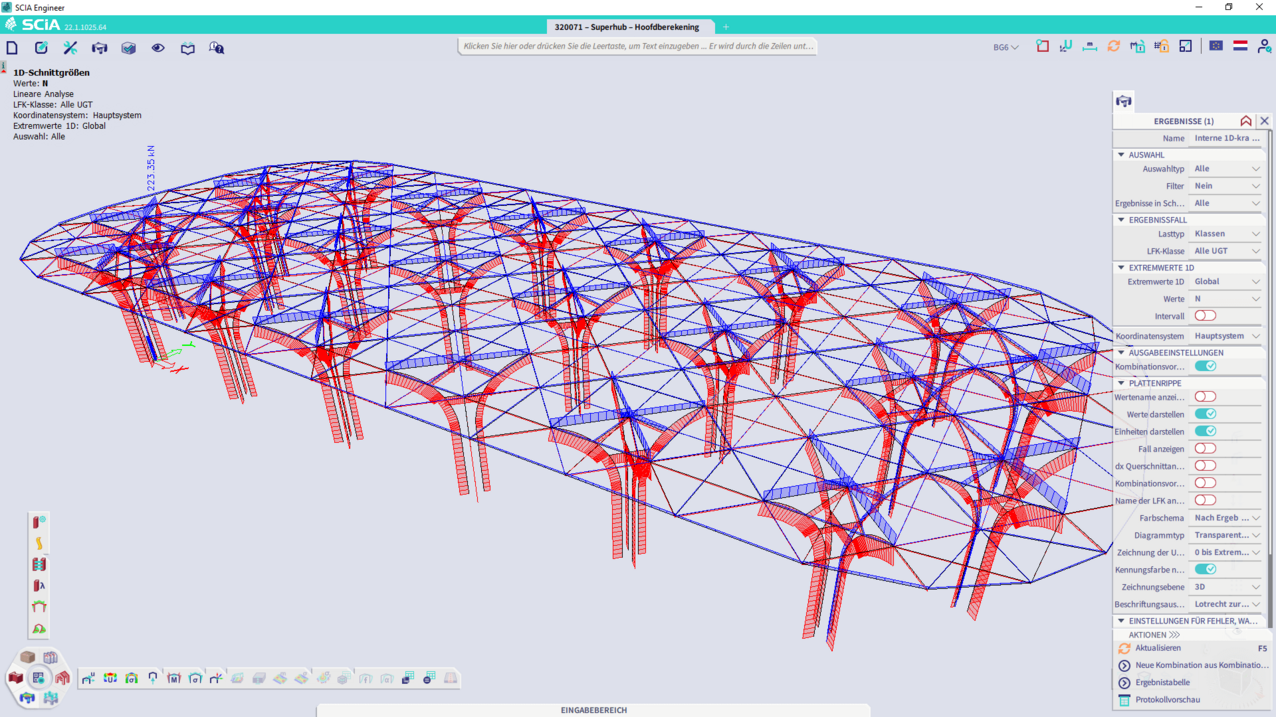

Load-bearing structure captured as a 3D structural analysis model

The Dutch engineering firm Pieters Bouwtechniek, which was responsible for the structural design of the ‘SuperHub’, succeeded in ensuring the stability of the building thanks to the appropriate software, while at the same time preserving the aesthetics of the visible timber structure designed by the architect. ‘The complex interplay of forces in the cantilevered roof structure and its interaction with the tree-like timber supports could only be properly captured in a 3D analysis model,’ explains Steven van Eck, structural engineer at Pieters Bouwtechniek. The engineers therefore relied on the multi-material structural analysis software SCIA Engineer for the modelling and static calculation of the structural analysis model.

Iterative design process for connection details

‘We initially put a lot of effort into designing the connection details for the timber components, because the design of the connections has a significant influence on the entire load-bearing structure and its structural analysis. On the way to the final model, we tested various systems of continuous beams and single-span beams in SCIA Engineer in numerous iterations, in which the arrangement of the hinges and the rotational stiffness of the connections varied constantly,’ recalls van Eck. Meanwhile, the team saved a lot of time modelling the ‘tree’ columns. ‘We modelled a pillar with its four glulam columns and the beams as well as the steel connections and then duplicated them by copying and pasting in the grid,’ reports van Eck, who was able to model 90% of the structure in a very short time in this way.

Structural analysis with SCIA Engineer

For the majority of the calculations, the structural engineers carried out linear static analyses in SCIA Engineer. Because the building is located on the edge of an earthquake zone, earthquake analyses were also carried out using the modal method and the multimodal response spectrum method. The engineers determined the base shear force, which was then used to prove that wind loads are decisive over seismic loads. In addition, the SCIA ‘Connection Forces’ function was used to easily determine the forces of the governing connection details. SCIA Engineer's calculation report helped the team to quickly generate an output of the structural calculations for the documentation of the model. ‘I like using SCIA Engineer because, thanks to the many modelling and calculation options, I can create a customised and workable design for any project, no matter how complex, and let the software do the work for me,’ concludes van Eck.