Future-proof multi-generational living in a courtyard development

The chalice supports of the new Stuttgart Main Station are engineering masterpieces. Their reinforcement alone is an artwork in itself, deserving closer inspection.

After almost 15 years of construction, Germany’s largest building project is nearing completion. Most people associate Stuttgart 21 with its sheer scale and the media coverage it has generated. However, within the AEC industry, it is also known as a structural marvel: specifically, the enormous chalice supports that sustain the complex roof structure of Stuttgart’s new main station while allowing in natural light and ventilation. At the core of these iconic, free-form shapes lies a highly intricate reinforcement structure, made possible only through 3D planning.

The architectural design for the station was developed by Christoph Ingenhoven in collaboration with Frei Otto. It involves relocating the previously above-ground railway lines underground and transforming the former terminal station into a through station, thereby connecting Stuttgart’s East and North districts. This underground relocation allows Stuttgart’s Castle Park to extend up to the rear of Paul Bonatz’s historic reception building.

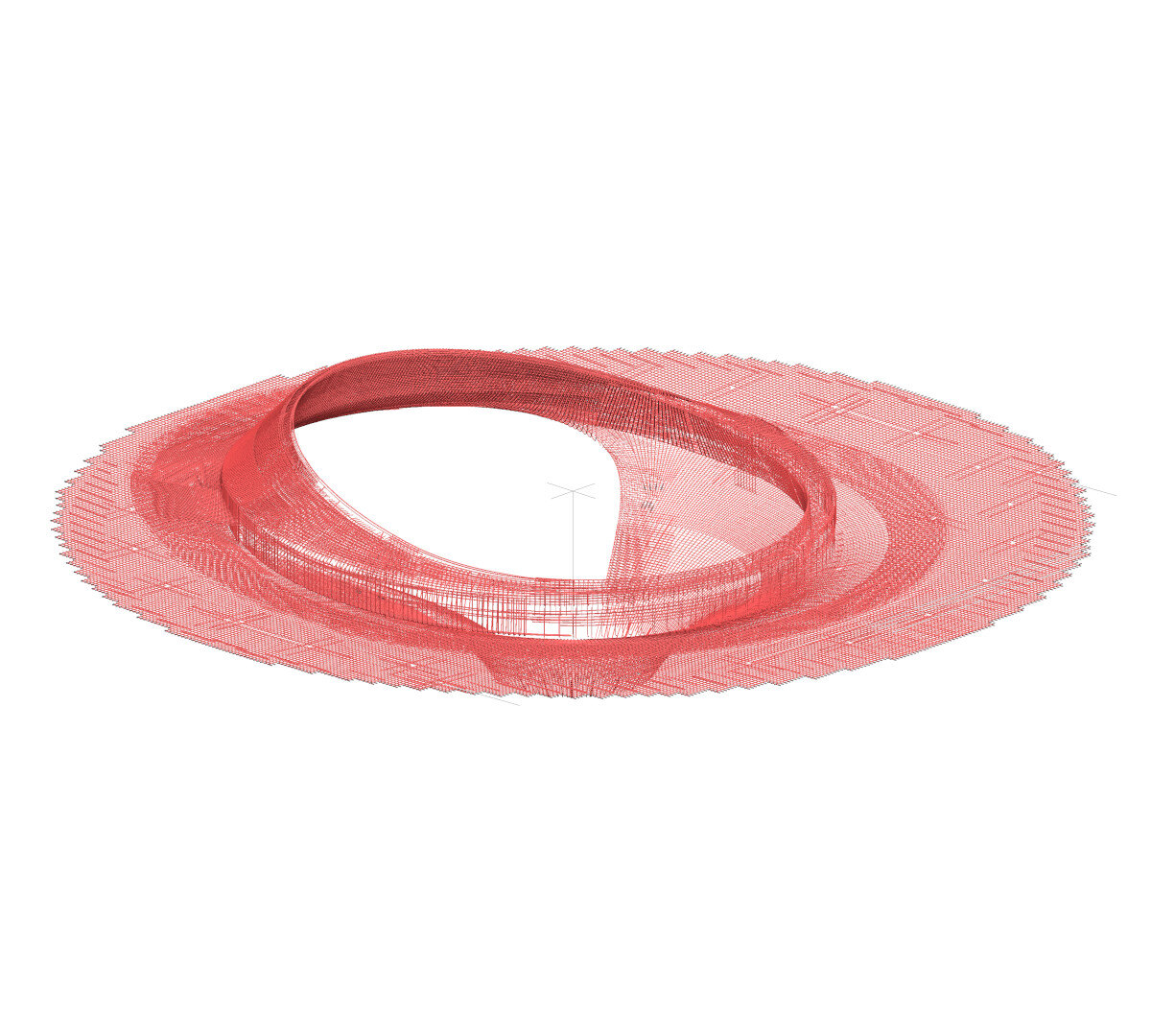

28 Chalice Supports for Stability, Light, and Ventilation

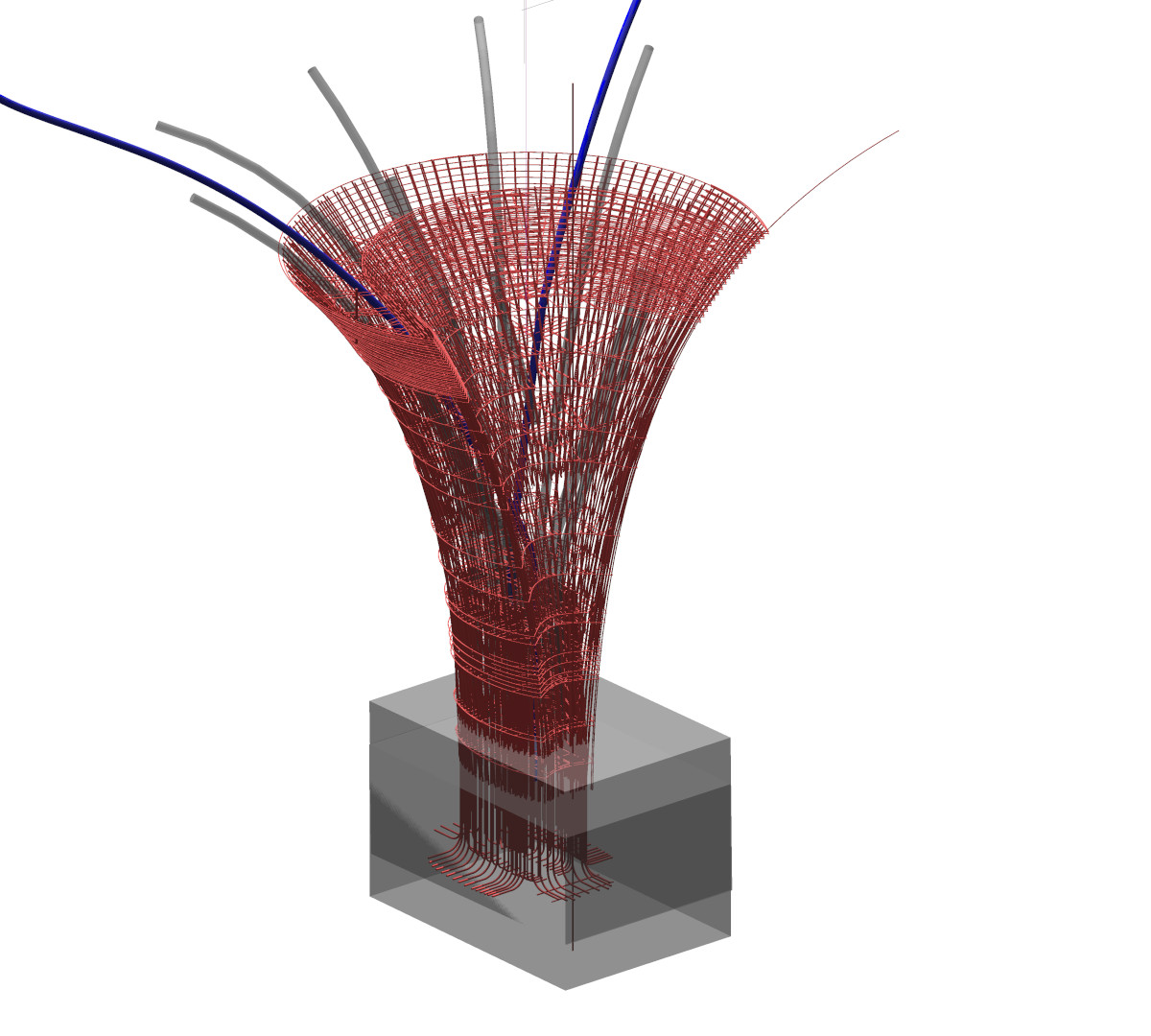

The station hall’s design presented two major challenges: providing an open, spacious atmosphere with natural light and ventilation, and handling the additional load from the new park as well as its intrinsic structural weight. The design process, which involved experimenting with soap film models, eventually resulted in the famous chalice supports. This solution emerged through extensive iteration and collaboration. A total of 28 piers support the shell roof with its added loads, simultaneously forming large light openings. Their design minimizes the station hall’s structural height and material use – making it a feat of engineering, indeed.

Chalice Supports Reinforcement: An Artwork of Its Own

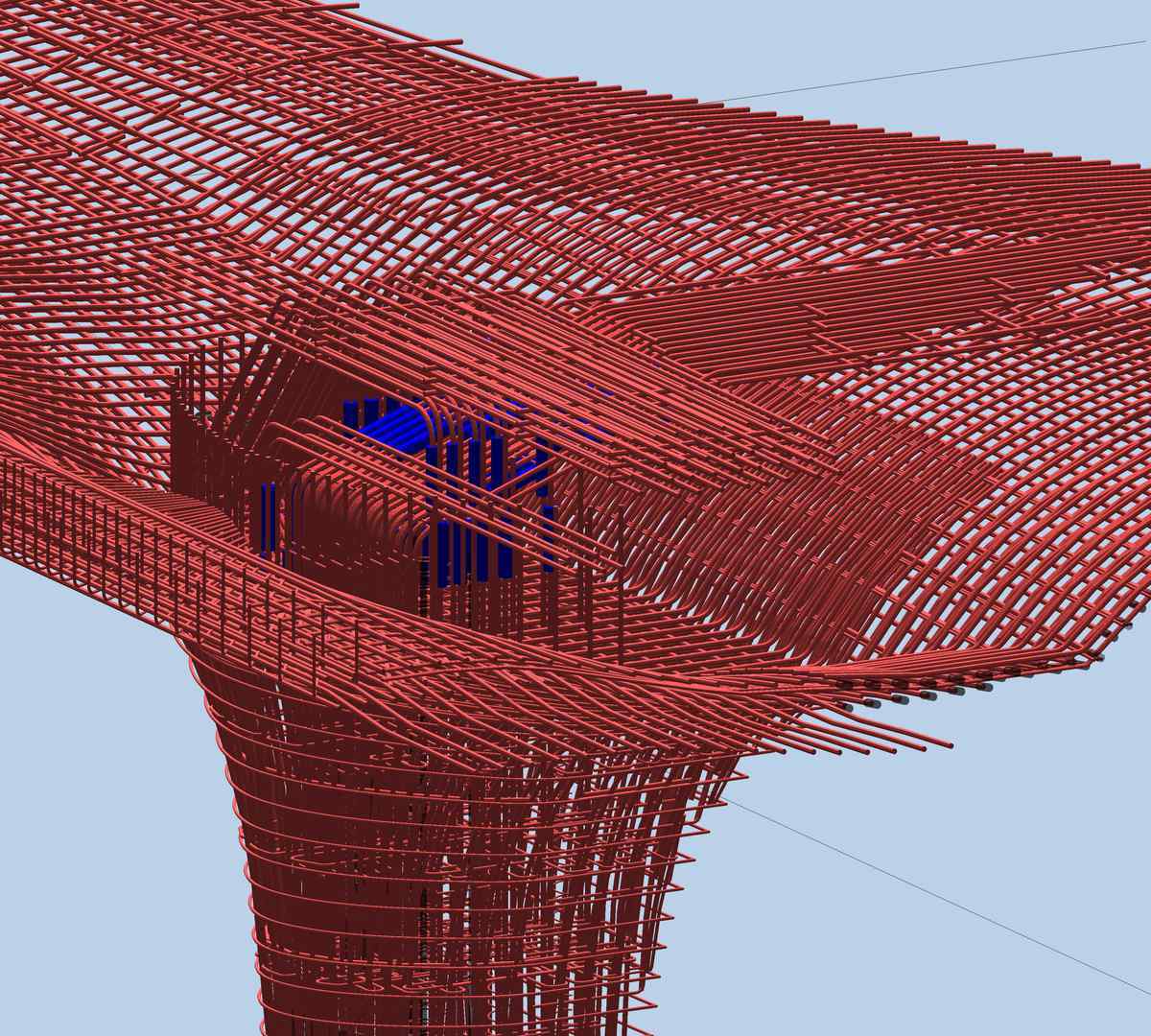

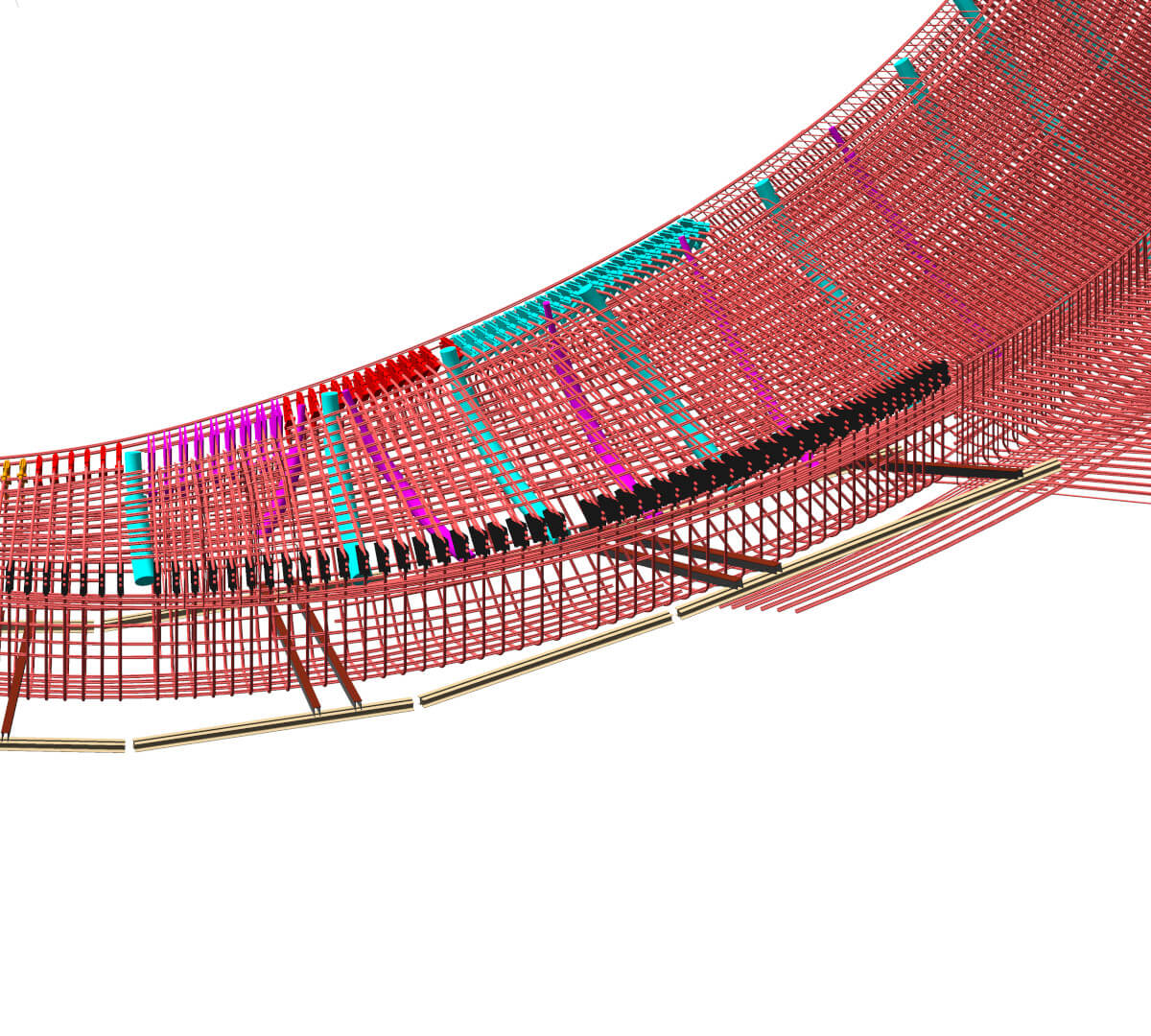

The Stuttgart office of Werner Sobek was responsible for the structural and facade planning of the underground station, including the reinforcement design for the chalice supports. This task was highly complex – the geometry of the supports varies constantly in thickness, includes both synclastic and anticlastic curved areas, and requires a mix of circular and rectangular reinforcement systems. The high demands on the visible surface required extreme precision when bending shapes and allowed minimal deviation in concrete cover.

Werner Sobek’s response to these challenges is nothing short of an artwork. A reinforcement model in Allplan was created for the reinforcement planning, including not only the bars but also all reinforcement-related inserts as well as concreting and compaction spirals. The complexity of the reinforcement is evident in the number of plans generated from the model: each of the 14 inner chalices (except for one special chalice) required about 350 DIN-A0 drawings, with 300 tons of reinforcement steel. Each of the 14 outer chalices required 400 drawings and 350 tons of steel. In total, the roof was represented in 12,000 reinforcement drawings.