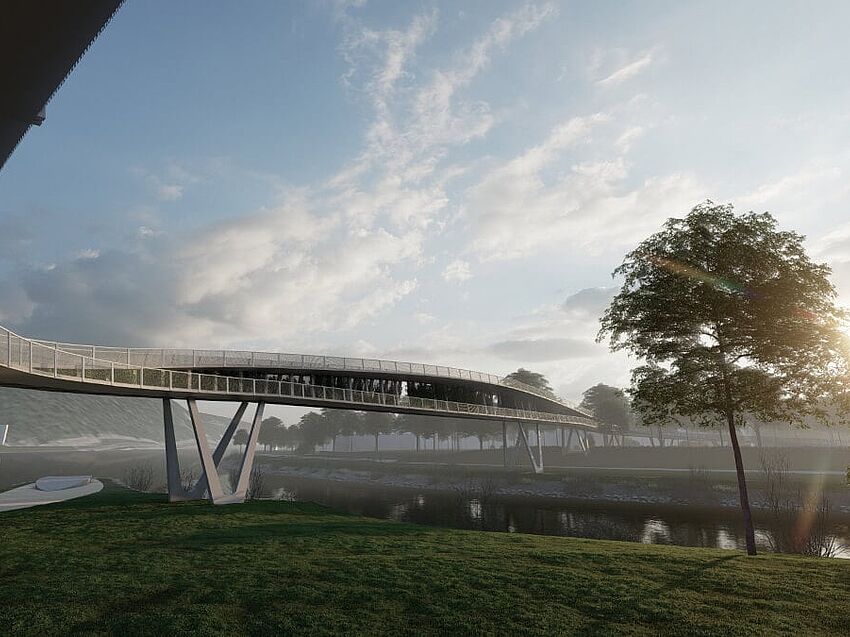

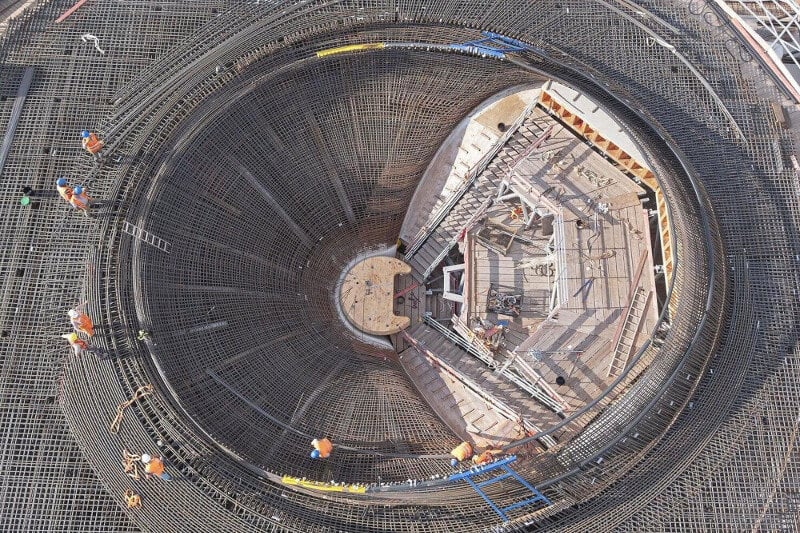

With building and infrastructure designs becoming ever more ambitious, designing concrete reinforcement to fit organic and freeform shapes presents unique challenges for structural engineers. Not only does the reinforcement have to fit the shape, but design codes must be adhered to and accurate drawings and documentation produced. Achieving these requirements on non-standard components – without any errors or discrepancies – is incredibly time-consuming. However, with advanced 3D modeling software, complex reinforcement challenges can be solved quickly and easily.

Efficient Reinforcement Design

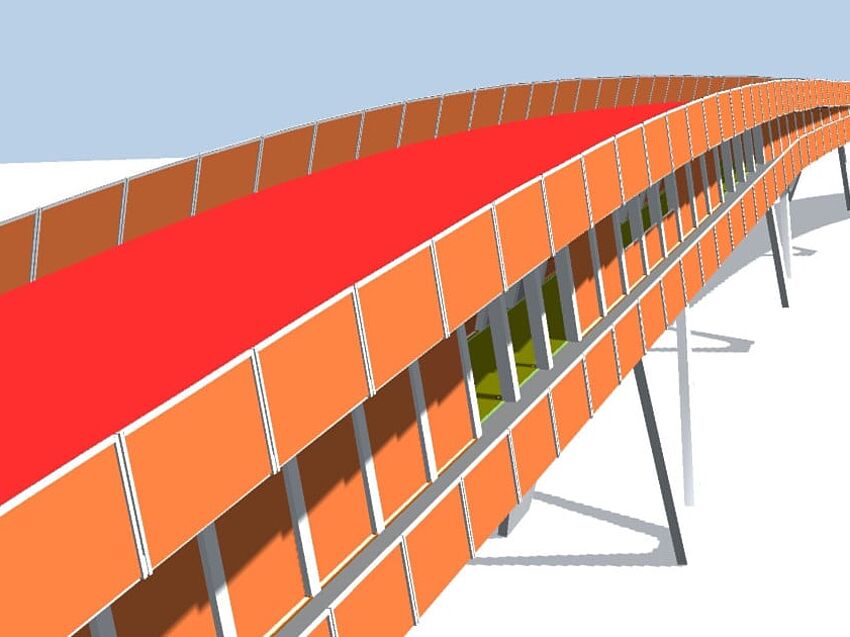

One of the benefits that 3D concrete modeling software offers is that it recognizes shapes and volumes as objects, as opposed to a collection of lines. In ALLPLAN Engineering, any shape that can be modeled can be reinforced – even freeform models. Once the object is modeled, producing the reinforcement model is extremely quick. The program understands how these volumes behave, so placing reinforcement is a simple matter of specifying the cover depth, bar size, and spacing, and the reinforcement will automatically wrap around the edges where required. The engineer retains control over the model and can quickly amend the reinforcement by adjusting the properties – such as bar shape, hook lengths, cover depth, and more – and the model will update automatically.

Improved Visualization

Using 3D reinforced concrete modeling ensures greater accuracy, particularly for complex shapes. Being able to visualize the finished result lets engineers identify issues before they are found on site and provides assurance that the designed reinforcement will fit within the component. However, ALLPLAN Engineering includes tools that go beyond a visual check, instead using clash detection analysis to identify any collisions between reinforcement and components. Errors and discrepancies can be fixed before the design phase is completed, for fewer issues during fabrication and construction.

Increased Accuracy

Complicated reinforcement designs present additional challenges around accurately quantifying the bars and creating bar lists or bending schedules. Even for standard beams and columns, this can take a considerable amount of time – with freeform shapes, the additional complexity can add a significant time element for calculations as well as checking, particularly if special bar shapes are required. Yet with 3D rebar CAD software like ALLPLAN Engineering, the quantities are calculated automatically from the reinforcement model and are updated as the model changes. The program will quantify every different bar shape, removing the manual labor from the process, improving the accuracy, and drastically reducing the time required.

Efficient Documentation Production

Producing accurate documentation is another strength of ALLPLAN Engineering. Because the information is taken directly from the reinforcement model, it is quick and easy to extract a section or view from the model and place it on a drawing layout. Similarly, there are a wide range of code-compliant reports which can be inserted onto a sheet with all the relevant information included using just a few clicks. This saves time re-drawing sections and views or inserting schedules like bar lists, particularly as each detail updates in line with the changes made to the model. Creating a completed set of accurate reinforcement documentation has never been easier.

Choosing Concrete Modeling Software

ALLPLAN Engineering 3D modeling software makes reinforced concrete detailing and design faster, easier, and more precise. If you are considering transitioning to a 3D reinforced concrete modeling program, download our whitepaper, 8 Considerations for Efficient Reinforcement Detailing, to discover what aspects to consider when choosing rebar CAD software.