Reactivation of the Siemensbahn: KREBS+KIEFER relies on ALLPLAN

The structural rehabilitation of existing suspended road infrastructure is a hot topic around the world. Often, it’s possible to perform maintenance to bring these structures in line with current safety standards, but the intervention depends on the level of knowledge that can be acquired about the infrastructure in question. However, with this data, a numerical model can be created to analyze the behavior of the structures and determine their stresses. Meanwhile, the geometric model allows the study of connections, nodes, and structural elements. To illustrate this, engineer Francesco Fanigliulo from Studio di Ingegneria delle Strutture in Cosenza shares his insights on utilizing a 3D Building Information Modeling (BIM) model, developed with ALLPLAN and ALLPLAN Bridge, for the comprehensive rehabilitation of two viaducts in Italy.

Project Background

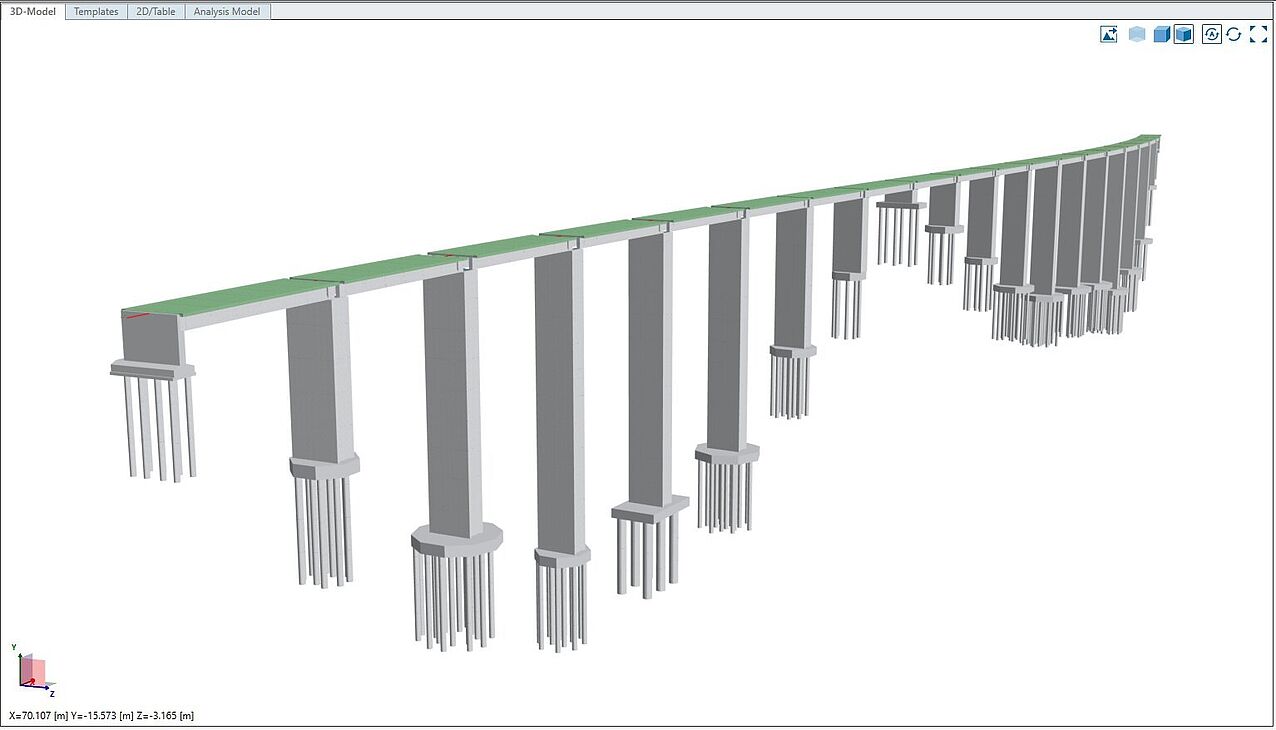

On the A2 Mediterranean highway lies a crucial set of infrastructure: the Friddizza viaducts. Comprising two parallel structures built approximately 50 years ago, the North and South Friddizza, these viaducts are a critical part of the motorway network, facilitating the seamless flow of traffic across varying elevations and longitudinal profiles.

The North Friddizza stretches across 627 meters with 19 spans, featuring supported decks held between abutments and piers for the end decks, and between piers for the inner decks. This design enables a structural scheme of simply supported beams. In contrast, the South Friddizza, albeit similar in construction and geometry, comprises 8 spans and extends over 264 meters. Despite the difference in span numbers and pier heights, both viaducts share a construction principle that allows for a unified approach to stress analysis and structural integrity checks.

Central to both structures are stem-type piers with multiconnected sections, supporting decks with a span of 33 meters and a net girder span of 32.5 meters. The decks present a comb-type cross-section, with parallel beams and orthogonally arranged stringers that distribute loads and mitigate torsional stress on the beams. This arrangement is critical for maintaining the structural health of the viaducts, with a deck width of 9.3 meters, slab thickness of 20cm, and beam spacing of 2.4 meters, ensuring robustness and resilience.

The rehabilitation of these iconic structures was undertaken under a comprehensive 16.74 million Euro project funded by the Connecting Europe Facility (CEF) RELEVANT program. This initiative aims not only at static rehabilitation but also at seismic enhancement to accommodate both ordinary vehicles and exceptional transports in compliance with EU Regulation 2021/1328. This regulation details requirements for dual-use civil/military transport infrastructure, highlighting the project's significance for both civilian and strategic mobility.

Preserving a Legacy with Innovative Engineering

An accurate study of the work was carried out using ALLPLAN and ALLPLAN Bridge, which allowed the entire viaduct model to be studied taking into account the actual geometries surveyed. Two numerical models were created in order to undertake static and seismic structural analyses:

- A descriptive numerical model of the deck-pile system, along with a local FEM model for the study of the stresses of both viaducts using LUSAS software;

- A global numerical model for each viaduct, one for the North Friddizza and one for the South Friddizza.

Computational models were performed to study the stresses induced by the acting loads, with boundary conditions compatible with those found on site. Local verifications were also performed based on the tests and investigations carried out and the assumptions made.

The initial focus centered on addressing the significant tension variations in the viaduct's prestressed reinforcements, which showed an average drop of 50%, exceeding expected norms. This led to a recalculated design stress, significantly reduced from initial estimates. Additionally, discrepancies in the actual vs. expected pier heights necessitated a reevaluation of the foundation's bearing capacity, which was further complicated by the unexpected soil-structure interactions due to the piers' varied embeddings. Through detailed material assessments and structural investigations, including core extractions and geoelectrical surveys, the team gained insights into the structural integrity and material conditions, which informed their approach to reinforcing the viaduct's static stability.

Following the static rehabilitation, the attention shifted to enhancing the viaduct's resilience to seismic activities. Building on the foundation of previous seismic dampening installations, advanced numerical modeling was used to assess the structure's seismic vulnerability accurately. This involved both the local and global models to analyze stress distributions and seismic response. A novel intervention proposed the use of an external kinematic chain to mitigate horizontal seismic forces on the piers, effectively reducing stress at critical points and ensuring a more robust seismic performance. This dual-phase approach, leveraging cutting-edge software and innovative engineering solutions, aimed at not only restoring but significantly improving the viaduct's resilience to both static and seismic challenges.

Future-Proofed Viaducts

The chosen intervention method involved the innovative use of carbon fiber reinforced polymers (CFRP), high-performance mortars, and multidirectional high-slip bearings. The structural rehabilitation strategy uses CFRP in two forms: as foils applied to the lower surfaces of the beams to bolster bending resistance, and as fabric wraps at the beam ends to enhance shear capacity. This approach ensures the structural elements are fortified against future stresses while preserving the integrity of the original construction.

For the piers, a key component of the viaduct's support system, the rehabilitation plan introduces high-performance mortars. These materials are selected for their dual benefits: their slender profiles maintain the structure's seismic response characteristics by not adding significant mass, and their advanced composition offers superior reinforcement. This method effectively addresses the degradation of existing reinforcements and integrates seamlessly with the use of carbon fiber enhancements to provide a comprehensive upgrade to the piers' resilience.

For the seismic improvements, multidirectional high-slip bearings were installed at the top of the piers, which ensure the absorption of deformations due to temperature and horizontal actions. Instantaneous forces, such as seismic, braking, and wind forces, are transmitted to structural elements reinforced for this purpose or where the action induces less stress.

By integrating these innovative solutions, the project not only addresses the immediate needs of the viaducts but also sets a benchmark for future rehabilitation efforts, ensuring that the Friddizza viaducts continue to serve as vital arteries on the A2 Mediterranean Motorway for years to come.

+++ What is ALLPLAN Bridge? - A powerful parametric BIM solution for bridge engineers, combining all phases of bridge design from highly detailed model creation, including prestressing tendons, to the integration of the construction process, structural analysis with code-based design, and drawing production, in one solution. You can find more information here. +++