Airship Hangar Mülheim: A Masterpiece of Innovative Timber Construction

Rebar detailers are not only interpreters, the core of their skill set lies in problem-solving. They put the pieces of a puzzle together to create the right drawing, and in turn, the correct fabricated rebar. The adage, “You aren’t building a Swiss watch,” really means precision isn’t necessary. While this might be true in some cases when detailing rebar, it really isn’t the right approach to this job.

There are many components that go into a concrete pour, all of them vital. Other trades depend on the correct reinforcement, and in a sense, not interfering with their work. As with any major project, a successful outcome is dependent on team work and collaboration. Coordination between the engineer, general contractor, rebar site foreman, and the fabrication yard is crucial.

Detailers must always ensure they are working with the engineer’s latest set of drawings. Usually, there is no direct contact with the engineer, and any communication is done through the general contractor (GC). If there is information that’s needed, or t missing, the detailer must inquire with the engineer through the GC in the form of an RFI; request for information. Generally, two weeks is a standard turnaround time for this request.

A great deal of information is passed between the GC and the detailer. As mentioned already, mainly in the form of RFI’s. Also, any changes to the project that require a change to the contract price (either as an addition or a subtraction), construction schedule, start dates, pour dates, pour breaks, and drawing submission dates are all communicated with the GC.

The rebar site foreman is the person that supplies the detailers with on-the-job information, such as maximum bar lengths they can handle on a particular site. For the rebar drawings, they notify the detailers of their preferences on what they would like to see; such as number of drawings per elevated slab. It could be one drawing per layer, or one drawing for each layer direction. Detailers also receive the information as to when they need the bar on site for a pour. If needed, detailers also specify how they want to support the bars; with chairs, bolsters, bricks etc.

The fabrication shop keeps the detailers informed on the maximum truck weights, minimum safe bending numbers, as well as lead time. Lead time is crucial, and in most cases, dependant on what is being fabricated. The fabrication shop requires two weeks from the time they get the bar list information from the detailer. Detailers must take that date into account when planning their workflow.

In the ideal scenario, all drawings are submitted to the engineer for approval and returned to the detailers in plenty of time to accommodate the pour date of the concrete. This is not often the reality. Detailers get the engineer drawings and the rebar is expected to be on site within a relatively short period of time.

First, they receive a concrete pour date for the area from the GC. Knowing that the engineer needs to review the placing drawings for conformity, and their turn around time is two weeks, so the detailers must ensure they are in his/her hands at least two weeks prior. Next, they need to determine how long it will take to create the detailed drawings for the area that needs to be poured, also allowing for any time it might take to receive the answers to RFI’s. The timeline could be one or even two weeks to detail the drawings. Overall, from the start date to the pour date, detailers need approximately four to five weeks.

The Future of Rebar

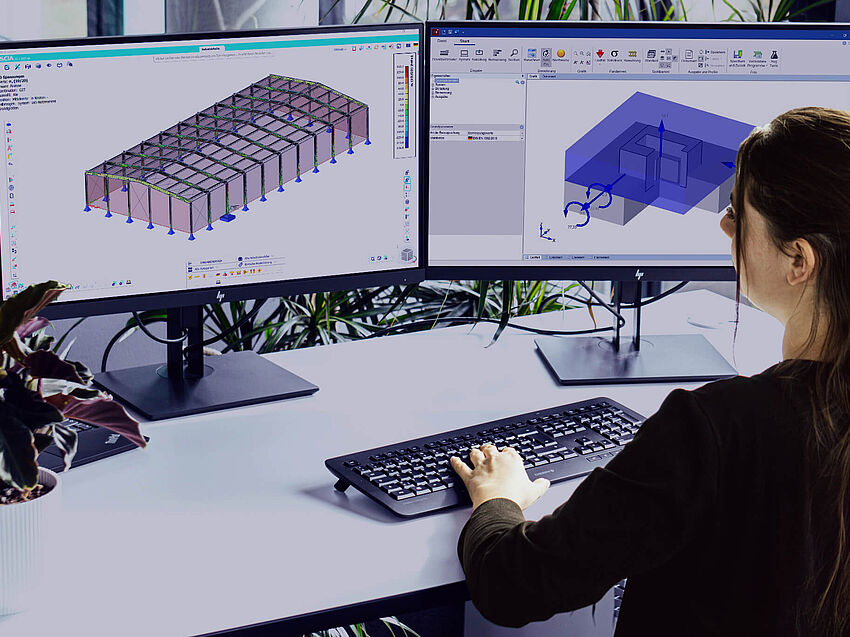

For a rebar detailer to do their job effectively today, they need a computer and the right software. In years prior, the common-held belief was that the drawing board detailer was much faster and more productive than the detailer working on the computer with CAD software. We would hear them out and give them that part of the argument only to counter with our own thoughts. Many thought you could be faster with the initial submission, or first round of drawings, but when it came to making changes, the software proved faster, because not everything had to be redrawn. The CAD software now is faster all around.

Now, another argument is brewing amongst us in the AEC; 3D and BIM, versus 2D. While 3D is a component of BIM, it is not BIM in and of itself. Most would agree that 3D rebar is faster than 2D rebar. In all actuality, it is not faster, but close to or equal in speed. However, there are real benefits to constructing in 3D and then detailing from that. There remains much scepticism as to the importance of 3D rebar at the detailing level. It may be hard to conceive of now, but 3D will be the only option in the future.

What is 3D/BIM to a Detailer?

In an age of technology, why wouldn’t 3D be important to a detailer? One can only imagine the significant value it can bring to their job. Visualization is the biggest plus. For a detailer, whether a junior or senior, to be able to see what they are creating in 3D, they’re able to better understand the various levels of development and can adjust to make things fit accordingly. When modeling a bar in 3D, you can see if that bar is sticking out of the concrete, interfering with other rebar, or interfering with other factors; such as, structural steel, mechanical or plumbing openings. With 2D modeling, there was no way to detect these clashes between the disciplines until they happened on site, causing strained communication and money lost in time and materials. It often wasn’t until two to three days before the pour that these problems were discovered.

Additionally, if the rebar went out wrong or something changed in the field, the detailers would just cut and fix it. This makes for a very messy situation. Rebar detailers are not responsible for modeling any potential conflicting components, as they rely on receiving models from the other subcontractors and coordinating that way.

Model coordination is now key for a detailer to be effective, and to eliminate a lot of the site issues that occur. Each sub-contractor has their own model they work from. All these models can be brought together to detect clashes in BIM software. Rebar detailers need only worry about the structural steel components, like embedded plates, steel columns and beams. For plumbing and mechanical, they look for penetrations in the concrete and determine if the rebar works, or if these openings need to be adjusted.

It’s crucial for a detailer to see how their pieces fit together, like where a column intersects a beam and ties into a slab. They deal with problems such as bar congestion, bar layering, hook dimensions, lap locations and bar spacing, or lack thereof. The idea behind all the coordination, visualization is to make the job of the placers as easy and as smooth as possible.

Software & Rebar

Any existing or aspiring software company needs to understand the job and complexities of detailing rebar, and the workflow the detailers adhere to when creating the placing drawings. We understand, and we want potential clients to know we will do what is necessary to adapt and develop the essential tools that a detailer needs to effectively do their job. We truly believe that our software is the best available option on the market. We strive to be innovators who understand the needs of our customers, their customers, and the industry at large. We believe that behind every good detailer should be a great detailing program.