Rarely is one construction project the same as another – even if the building itself is the same, the site conditions or another facet may be different. That said, most projects use many of the same materials – for example, structural steel, reinforced concrete poured in-situ, or precast concrete manufactured off-site are some of the most common. Traditionally, designing with any of these materials could have required separate specialist design software. Yet having 3D BIM software which can handle the unique requirements of each material type from within one solution, from design to build, is a distinct advantage in terms of efficiency, productivity and optimizing buildability. This is how architects and engineers can benefit from a multi-material approach.

Why Materials Matter

Every project ever designed uses a range of materials, so why does an integrated solution matter? The answer is that each material has unique construction requirements that affect the design process and workflow. In turn, these requirements can create time-consuming tasks during the design stage, when time could be better spent on creativity, optioneering or improving quality and buildability. Additionally, with increasing requirements to select and make construction choices to deliver ever more sustainable and hybrid buildings, designing with different materials becomes even more important.

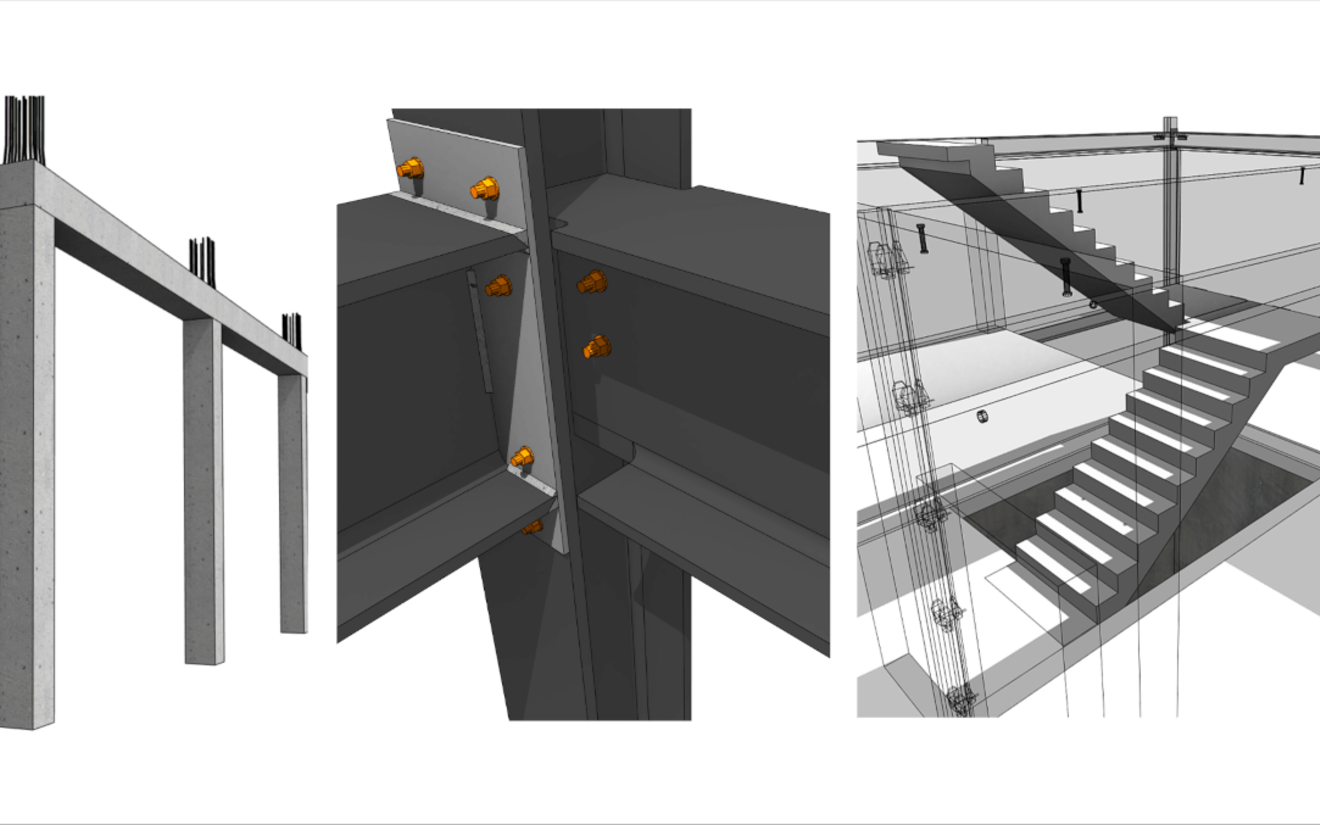

For example, modeling steel reinforcement for concrete can be a tedious activity, particularly if there are non-standard or freeform shapes that need to be reinforced. Modeling the bars accurately and detailing them (even if only in 2D) takes time, which can be exacerbated if there are any changes. Once completed, quantifying the reinforcement and any special shapes is laborious, as well as having a high potential for errors to creep in.

Precast modeling also requires reinforcement, but there are many other additional activities that need to be considered. How can each precast component be divided optimally for production, transportation, and assembly? Where should lifting hooks be installed, and how can the geometric information be efficiently sent to production machines? Without specialist modeling software, these design activities take up significant time.

Structural steel modeling presents its own set of challenges. With steel frames, there are many detailed connections to model, and if the design changes, updates are naturally required. Manually undertaking these tasks can be error prone as well as slow.

An Integrated Solution

Of course, design software exists that removes many of these issues and streamlines the design process for specific materials. However, instead of requiring several different programs that create outputs in different formats and may not transfer information easily between them, ALLPLAN 2023 offers an integrated approach with design solutions for the unique requirements of each material and construction approach.

This enables the coordination of different materials and construction methods in one common model enabling, for example, architects to better consider the economical and sustainable use of building materials, earlier, and in accordance with environmental requirements. And engineers and construction companies to then build directly on the architects' design and use it as the basis for structural analysis and detailing, MEP engineering, prefabrication, and construction. ALLPLAN 2023 supports superior workflows from the initial idea to the completed project, enabling time, cost, and material savings – for ultimate buildability.

Automated Reinforcement

Reinforcement detailing is characterized by high workloads and tight deadlines. Automated reinforcement helps to reliably complete recurring tasks in less time. With ALLPLAN 2023, it is now possible to reinforce several columns and walls of one type at the same time. In addition, there are numerous improvements in detailing. For example, columns can now have multiple stirrup types and continuous beams can also be reinforced in one work step.

With regard to the increasing requirements in BIM projects, the attribution of reinforcement has been extensively revised. In addition, there are many other various improvements; for example, several polygonal placements with different mark numbers can be connected – and combined into one polygonal placement, with one mark number, to streamline manufacture and implementation.

Diverse Steel Construction

Users now have the ability, in ALLPLAN 2023, to customize the start and end angles of Structural Framing Elements, which is necessary to accurately model structural steel . The Connection Toolbox now includes the ability to specify holes and end conditions. These features help engineers model most steel connections at LOD 300 and above, improving accuracy and the efficiency of communication when collaborating with detailers, fabricators, MEP engineers, and other BIM stakeholders.

Furthermore, the Connection Toolbox is written in Python and can be extended by users and developers. Column Splice Plate and Base Plate examples have been shipped with ALLPLAN 2023 to help get started with extension development.

Optimal Precast Concrete Design and Detailing

One of the newest innovations in ALLPLAN 2023 is the integration of tools for the design and detailing of precast elements. Planbar Essentials, one of the most innovative planning solutions in the Precast area, has now been incorporated into ALLPLAN, opening up new possibilities for capitalizing on industrialized construction. As a result, engineering firms can now design precast concrete elements of any complexity directly in ALLPLAN. Similarly, engineering offices and precast manufacturers can build on existing BIM models from architects and integrate them directly into the design process and manage their projects with ease.

Merging Planbar and ALLPLAN not only simplifies project coordination, but also enables new, even more efficient workflows. For example, precast elements can be created in a time-saving manner using functions in ALLPLAN, as well as PythonParts and – a brand new feature – the intelligent conversion of 2D stair sketches into fully parametric 3D components.

Save Time and Money, and Optimize Buildability

With no need for licenses for multiple software products, as well as the reassurance of no data loss between programs, having 3D BIM software that can handle all project phases and all materials, from design to build, makes sense. Coupled with the efficiency gains of an intuitive, easy-to-use tool, ALLPLAN 2023 can help achieve a multi-material approach for ultimate buildability and potentially significant savings for your projects. To learn more, download a free, 30-day trial.

Do you want to learn more about ALLPLAN 2023? Here you find an overview of all new features.