Future-proof multi-generational living in a courtyard development

Frankfurt am Main is known across Europe for its unique skyline. It will soon be enriched by a dazzling tower. The OMNITURM will be built right in the middle of the Frankfurt banking district by 2019. At over 190 meters, it will not only be the sixth tallest building in Frankfurt's illustrious skyscraper ensemble. It will also be the first high-rise building with mixed use in Germany that in addition to office and residential space will also provide public areas. In addition, it is part of a long list of important buildings that were built with high-strength reinforcing steel SAS 670 from Annahütte steel works.

The client is well-known in Frankfurt. Tishman Speyer, with the MesseTurm, the OpernTurm and the TaunusTurm, is already responsible for three other icons of the Frankfurt cityscape. The OMNITURM is currently being built diagonally opposite the TaunusTurm on the corner of Große Gallusstraße/Neue Mainzer Straße. The star architect Bjarke Ingels from BIG was brought on board for the ambitious project. His design provides for an almost rectilinear, classic glass tower. Almost. Were there not a surreal helical turn just under the middle of the building.

Changes to the program

This detail is by no means arbitrary, but rather denotes a change in use within the building. At the lower end, and therefore less conspicuous, the stories are offset to each other, thus creating balconies and canopies on the east side and an arcade on the west side. This public space is adjacent to linear office spaces. The following spiral turn indicates the change to the living space and creates spacious, terraced outdoor areas with expansive views. On top of this is orderly office space again so that the office space is located in a total of 44,200 square meters, the apartments are in 8,200 square meters and the public space is in 1,700 square meters.

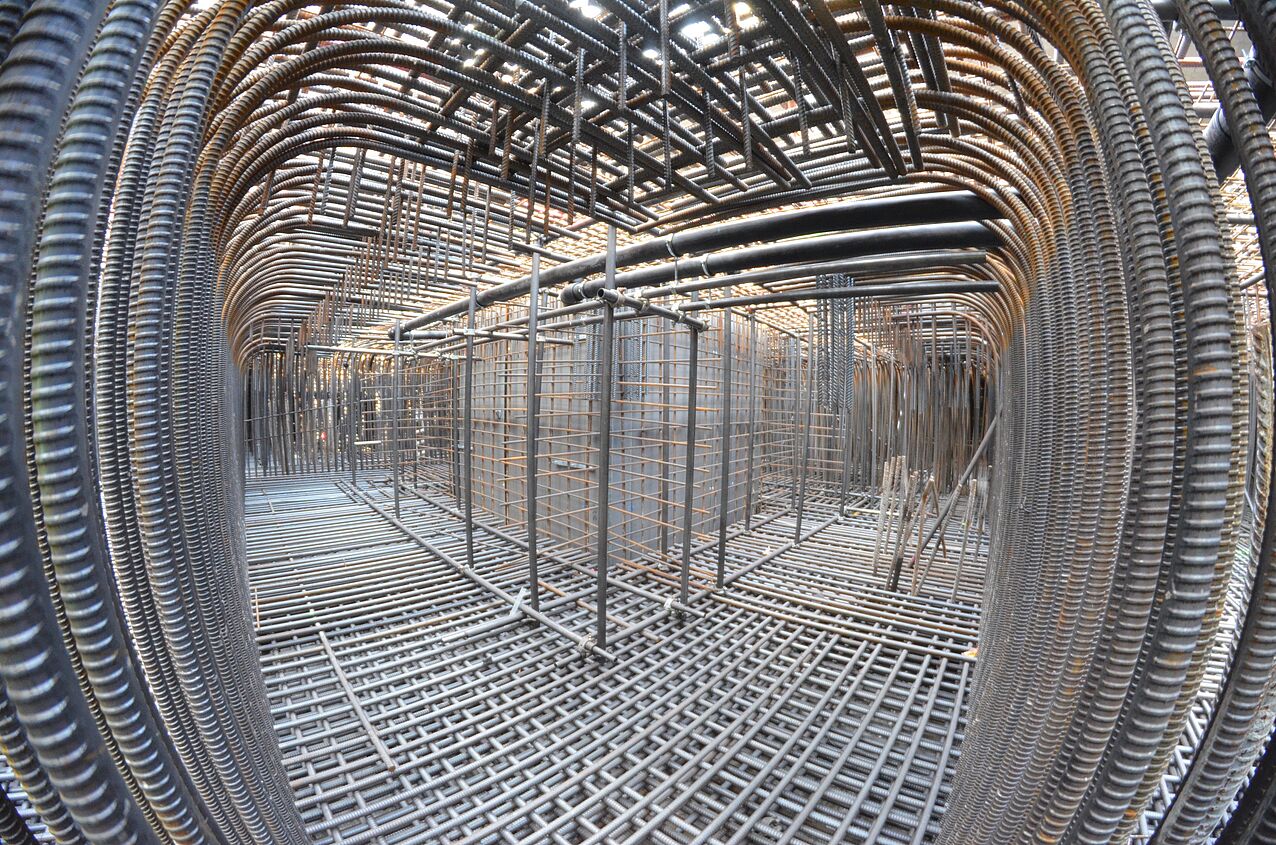

High-strength reinforcing steel SAS 670

A special structural feature of the OMNITURM is its reinforcement made of high-strength reinforcing steel SAS 670 from Annahütte steel works (SAH). This can transfer up to 34 percent more load than conventional reinforcing steel B500B. This makes it possible to significantly reduce the required reinforcing area, which offers cost advantages when it comes to material and the installation work. The threaded steel components have an endless screwable coarse thread, whereby the rods can be shortened or extended at any point and lap joints from coupler connections can be avoided. Moreover, the hot-rolled coarse thread is insensitive to mechanical damage.

The high-performance reinforcement has already been used in the OpernTurm and TaunusTurm in Frankfurt. Other prominent examples are the One World Trade Center, 432 Park Avenue or the Museum of Modern Art (MoMA) in New York City, just to name a few. With the OMNITURM, as well as with the aforementioned projects, the reinforcement from SAS 670 allows for a much slimmer construction method in the concrete supports being built, which ultimately leads to more usable space. This is a notable economic factor in cities with high rental prices such as Frankfurt and New York City.

Good news for ALLPLAN users: The catalog SAH SAS 670/800 for screwed-sleeve joints and couplers is integrated into ALLPLAN Engineering starting from the 2017 version.