As part of a Digipro project, ALLPLAN is working with three partners to research a system for automatic performance measurement using IoT and BIM. DigiPro focuses on the digitalisation of products, processes and business models in companies.

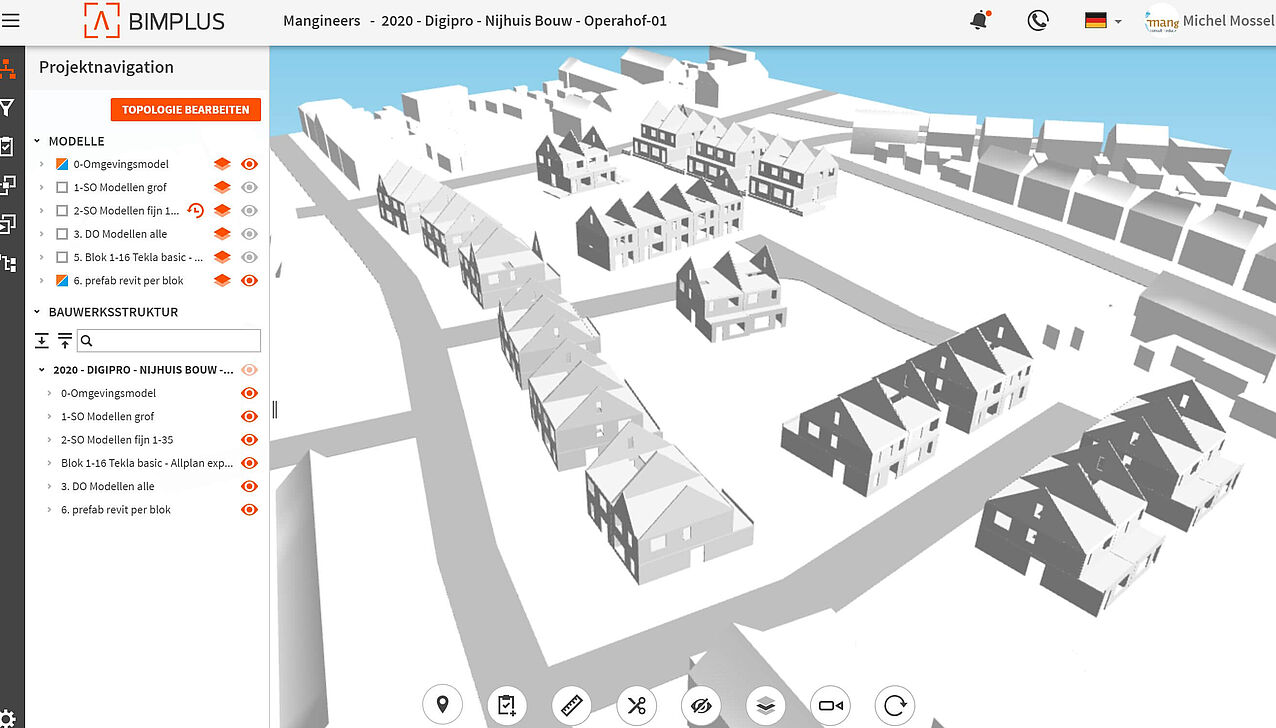

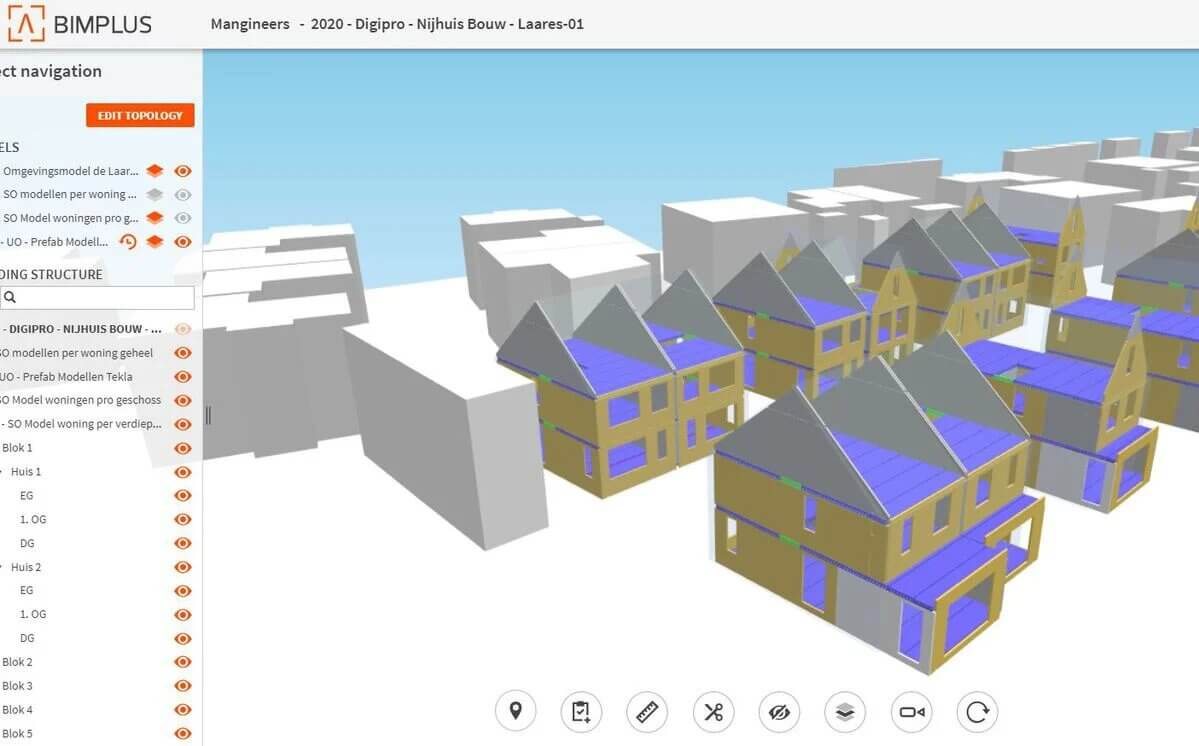

As part of the German-Dutch INTERREG program Digipro, a project is currently underway that aims to automate performance recording on the construction site using IoT (Internet of Things) and BIM (Building Information Modelling). A consortium of four companies - BuildersMind, mangineers, Nijhuis Bouw B.V. and ALLPLAN - is working on a solution for automated construction site monitoring that documents construction progress in near real time. Promising results have already been achieved in an alpha test phase on two construction sites of Nijhuis Bouw in Enschede 2020.

Technical innovation

The central technical innovation in the project is provided by BuildersMind in the form of a mobile (MACI) tracking box and the BuildersMind core. The MACI box is magnetically attached to a construction machine - in this case the hook of a mobile crane - and collects and transmits movement data from the implement to a monitoring device. The latter merges the data, evaluates it and integrates it into the BIM platform Bimplus in near real time. There, an overlay of the supplied as-built or actual data is automatically created with the planning or target data of a BIM model of the project, which can be used to determine and visualise the current construction progress.

Alpha test phase: 65 single-family houses in prefabricated construction

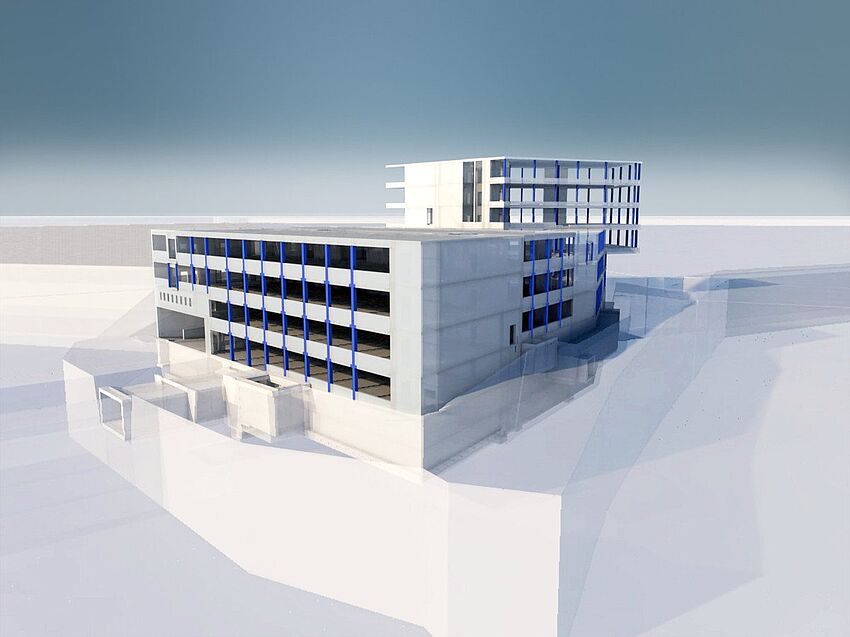

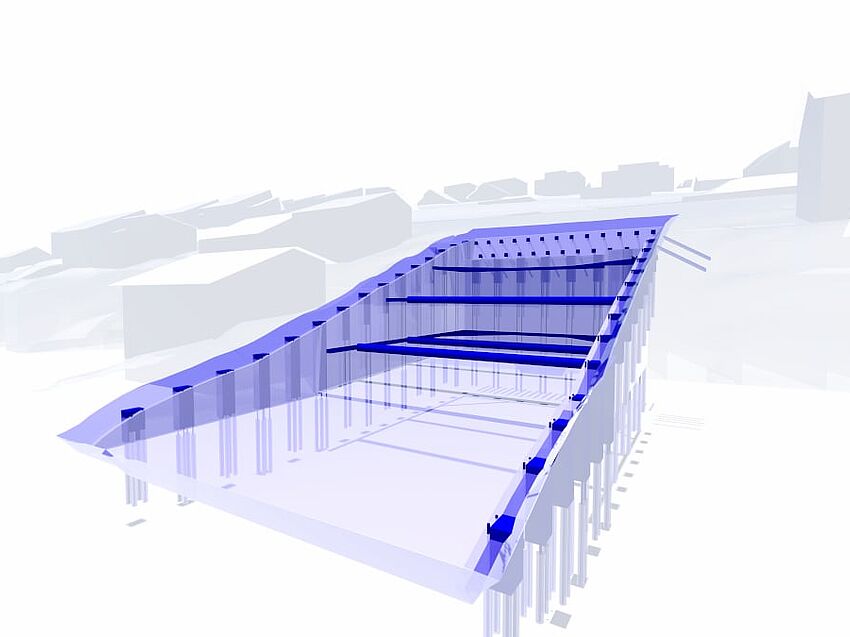

The system has meanwhile been successfully tested in an alpha test phase on the two construction sites "Operahof" and "de Laares" in Enschede, which comprise a total of 65 single-family houses in prefabricated construction. On the planning side, detailed BIM models were created by mangineers in three steps. In the first step, a visualisation of the surroundings and positioning of the buildings was carried out, whereby the zero point and actual geo-coordinates were aligned.

In the second step, a 3D volume model integrated the cubatures of the buildings. In this phase, simple as-built information such as positional data of the work equipment can already be integrated by connecting the BuildersMind system, and initial construction progress information (for example, the number of precast elements installed) can be recorded. In the third step, the 3D volume models were further detailed at storey and component level. These highly detailed models finally form the planning data basis for the automatic construction progress recognitionof the precast element assembly.

AI-based modules for component recognition

In the alpha test phase, the BuildersMind system has already been able to generate several 100,000 data samples per single-family house, with the help of which AI-based modules for component recognition have been trained. The modules in turn deliver specific cognitive services such as construction progress recognition of the prefabricated part assembly. The system is already capable of automatically generating a detailed performance calculation with installed quantities and associated times in near real time. Furthermore, the actual duration of work processes can be derived from this information for recalculations or the validation of effort values.

The information is output via Bimplus to a dashboard where it can be read. This is integrated into the Bimplus BIM Viewer.

In the future, further development of the proof of concept should also make it possible to refine the localisation in the BIM model at component level, integrate a 4D BIM model, perform a near-real-time target/actual comparison and create 4D construction progress forecasts for the precast assembly.