Today’s architectural firms, engineering consultancies, and precast manufacturers are navigating a challenging environment. A shrinking workforce, escalating project complexities, and an urgent demand for sustainable building practices, all amidst an enduring global labor shortage are some of the key issues. Coupled with ambitious aspirations to construct larger, more sophisticated structures, delivered swiftly and cost-effectively, has led to a need to achieve more with fewer resources.

Recognizing the potential of modern construction methods such as prefabrication in minimizing waste and reducing construction time, the industry is now looking towards design automation and customization as a key solution. See how this innovative approach can boost productivity, mitigate errors, and ensure resource optimization, for successful project delivery despite mounting challenges.

© SK Rapid Wien; The Allianz Stadium in Vienna is a perfect example of how prefabrication can speed up construction. In just 8 months, more than 5,000 precast elements and 150 precast stairs were produced.

How can automation help with industry challenges?

The architecture, engineering, and construction (AEC) industry is grappling with numerous challenges. A global labor shortage, exacerbated by an aging workforce and a lack of new sector entrants, is hitting the industry hard, leading to an increasing reliance on automation for streamlining processes and enhancing productivity.

Low productivity growth, another key issue, is partly attributed to outdated construction methods, despite the advent of modularization and prefabrication. Lastly, the industry’s shift towards modern methods of construction like prefabrication has spiked demand for standardized building elements, presenting new challenges around efficient design, manufacturing, and delivery. Automation is emerging as a vital tool in these areas, aiding in the design and management of prefabricated elements, and optimizing the precast manufacturing process.

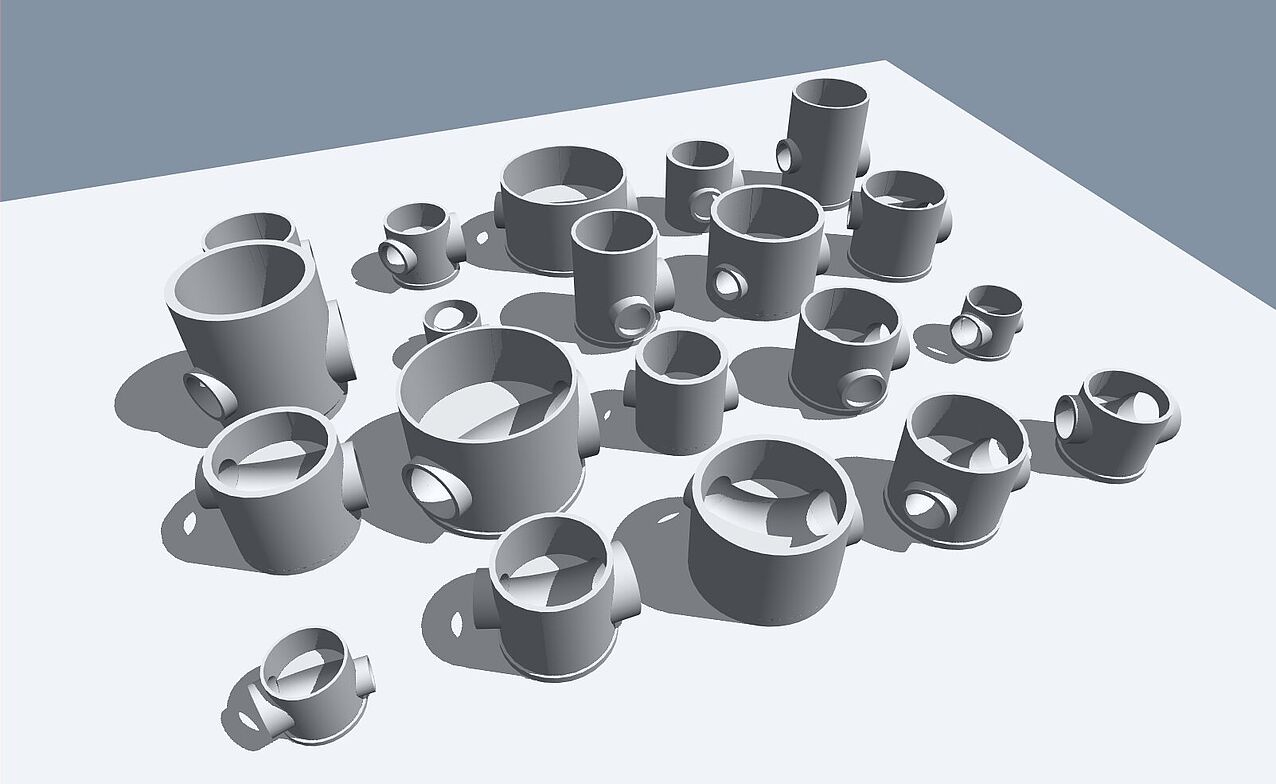

© ALLPLAN GmbH, Munich; When detailing buried vaults and junction boxes, openings are required for variety of services. These openings can be defined with just a few scripting nodes. This removes the need to manually model each opening.

Harnessing Automation Technologies for Enhanced Design Efficiency

The focus is turning towards advanced automation technologies that can streamline processes, increase productivity, and promote efficient design, manufacturing, and delivery of prefabricated elements. ALLPLAN BIM modeling software offers four such technologies: Visual Scripting, Python API, Bimplus, and Bimplus API, each contributing significantly to industry transformation.

Visual Scripting is a potent tool that enables designers to establish complex workflows effortlessly, thereby bolstering efficiency and productivity. It expedites design iterations and enhancements, leading to superior design quality and swift project deliveries.

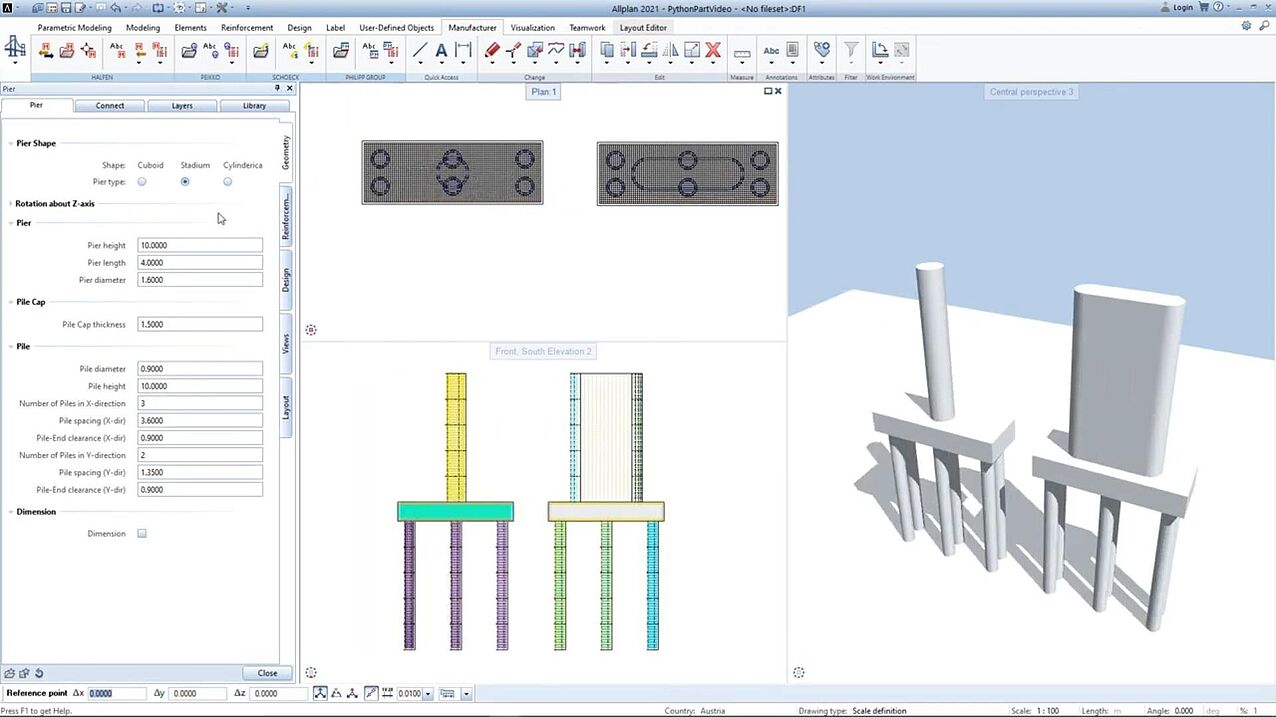

Python API interfaces with PythonParts in ALLPLAN, allowing for custom functions and automated workflows using Python, a popular and user-friendly scripting language. It automates tedious tasks, streamlines workflows, and minimizes errors, leading to sophisticated, accurate, and efficient designs.

Bimplus by ALLPLAN is a pioneering OPEN BIM platform that fosters collaboration among project stakeholders. It offers effective and efficient project data management, allowing for seamless content import and export, thereby improving collaboration, communication, and project delivery times.

Bimplus API enables the Bimplus platform to be customized to align with specific workflows and facilitates model integration into Bimplus. This feature promotes seamless collaboration among stakeholders, automates workflows, and improves efficiency, reducing errors and enhancing communication and design delivery.

© ALLPLAN GmbH, Munich; With the Python Part API, a developer can create complex customized and automated workflows with code. Python is a well-known and easy-to-use scripting language, making it easier to find a developer to help with the development.

Paving the Way for Enhanced Efficiency

The integration of automation tools into design, engineering, and manufacturing workflows represents a game-changing opportunity for the AEC industry. Through technologies such as Visual Scripting, Python API, Bimplus, and the Bimplus API, designers and engineers can automate their workflows, reduce errors, and enhance collaboration, ensuring they remain at the forefront of industry advancement. The benefits of automation are compelling, underscoring the need for firms to take advantage of these opportunities for improving their design processes.

For a more in-depth exploration of these automation technologies, as well as insights into effective automation planning, download our comprehensive white paper here.