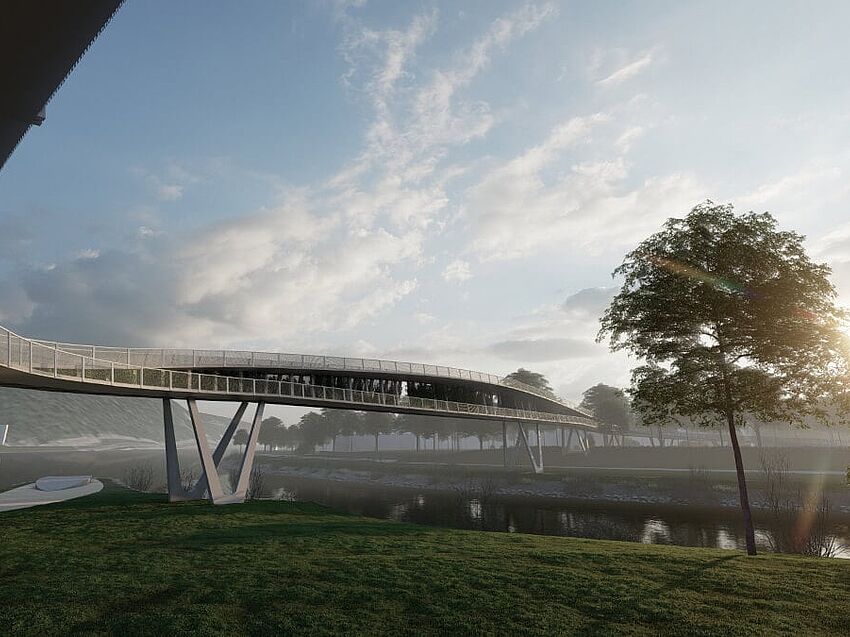

In Part 2 of the student design for a new bicycle and pedestrian bridge in Lahnstein, we take a look at its planning and post-processing with ALLPLAN and Lumion.

In the first part on Green Link Lahnstein, we were able to admire how great the bridge design for Lahnstein's Rhine promenade is. As a reminder, the concept with separate paths for cyclists and pedestrians and the green space this separation creates is too beautiful not to be built. In Part 2, we will now take a look at how the bridge was planned by the students.

Planning basis for the bridge: 3D model in ALLPLAN

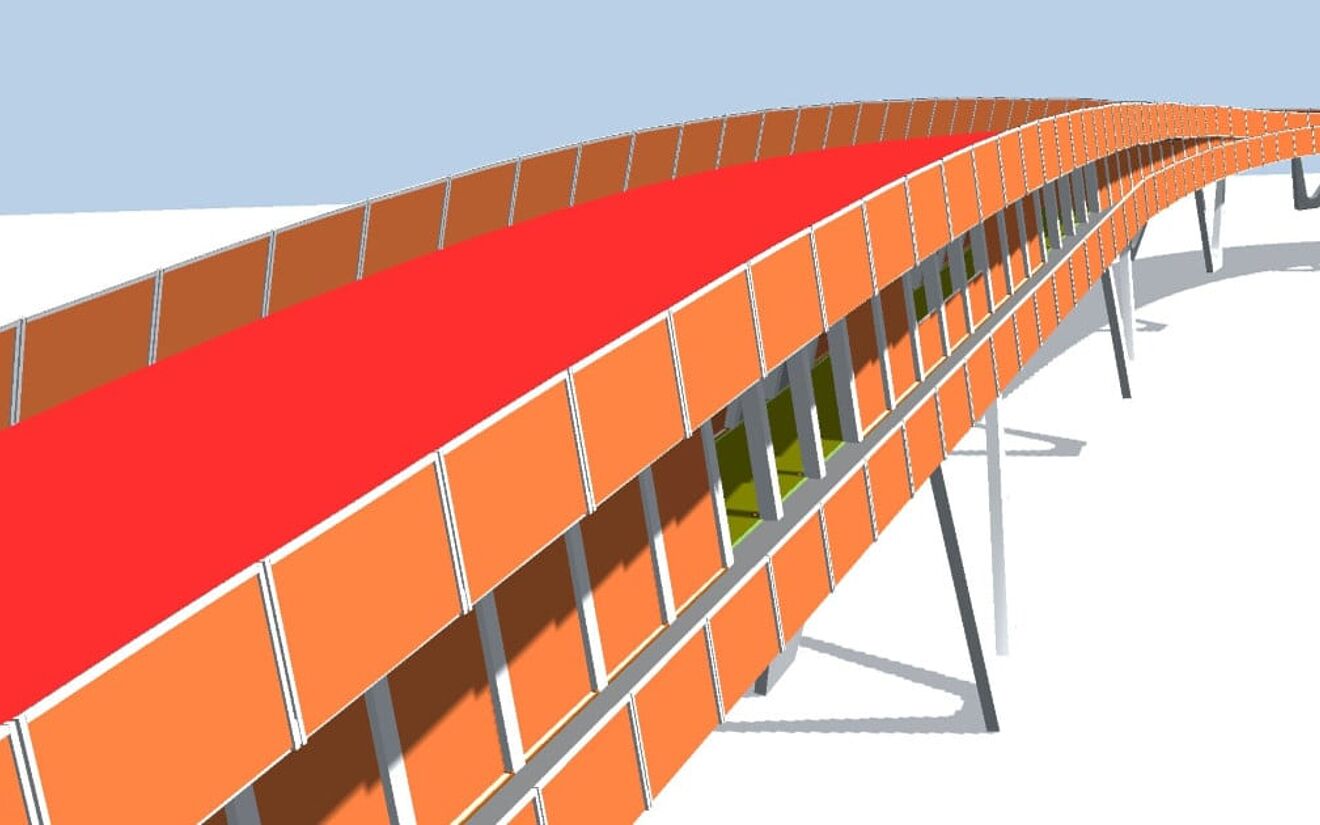

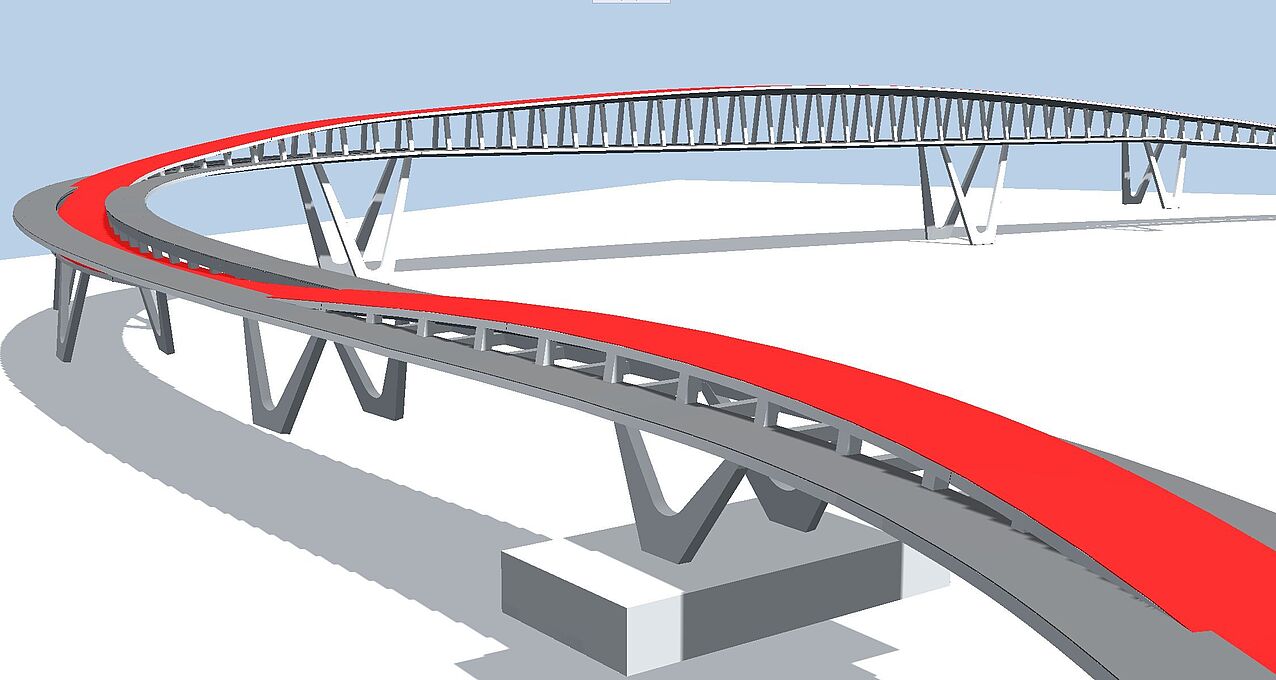

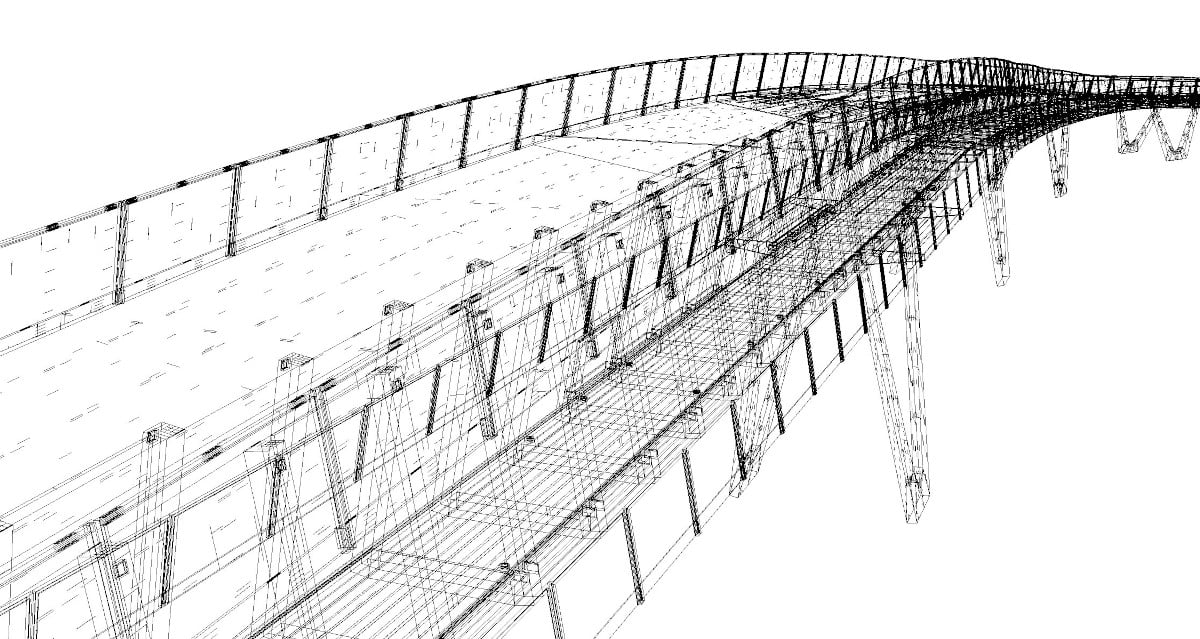

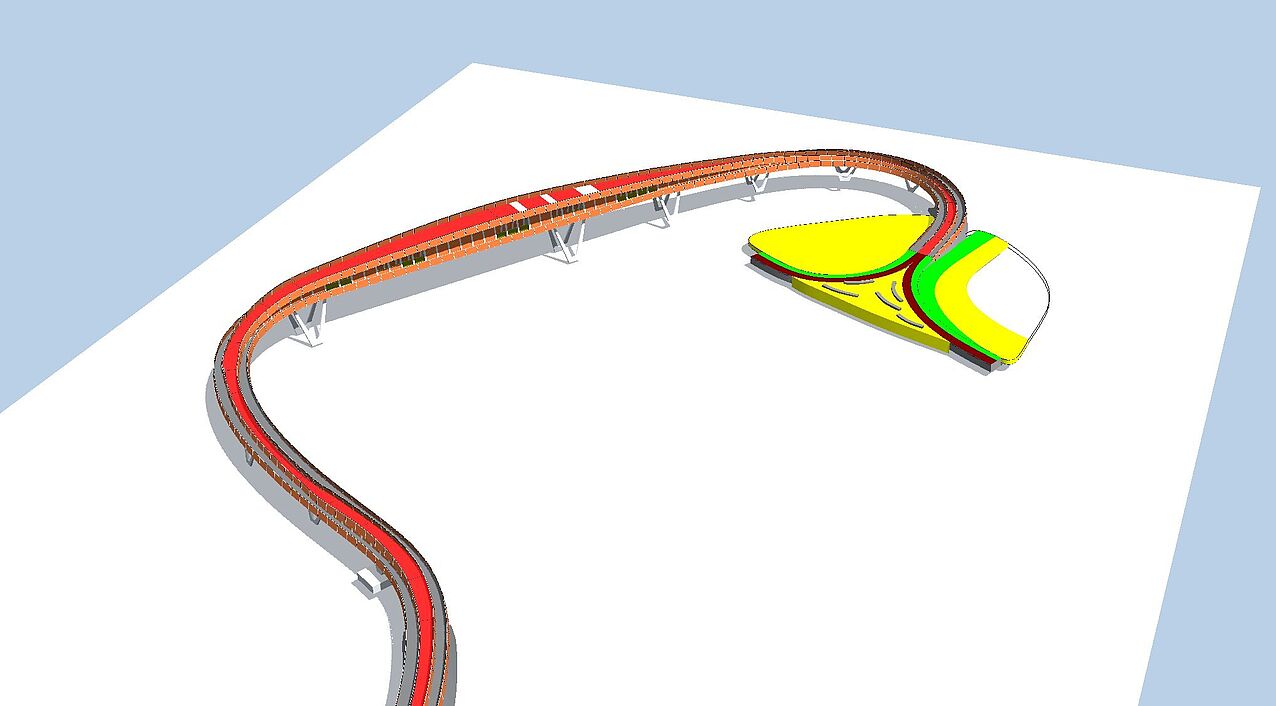

A 3D model in ALLPLAN served as the basis for the planning. A particular challenge in the modeling was the dynamic, organic shape of the bridge, which changes levels both horizontally and vertically. This is where the ALLPLAN functions of "Extrude along path", "Loft", "Convert 3D lines to 3D surfaces" and "Extrude 3D surfaces" came in handy for the students. With the help of these tools, almost any shape described in 2D or 3D lines can be converted into a three-dimensional body. The different sections of the bridge ultimately determined how the various tools were used.

Loft function connects different cross sections

The roadways were generated using the Loft function. For this purpose, the different cross-sections were first drawn according to the engineer's calculations. Each shape and position required a new cross-section, so these individual ramp sections (with a six percent slope) and landings (three percent slope) of the footway could be combined into a 3D body using the Loft tool. The same method was used to implement the various heights and widths of the bike path. Supports, plant troughs and grids, ramp pavements, cross supports and lights were again created from freely modellable 3D bodies, which were brought into the desired shape using the "Point Modify" tool.

Post-processing in Lumion

The railing also proved to be particularly challenging, as it had to be modeled as realistically as possible due to its special design and its function in the bridge's lighting concept. The curvature and gradient of the ramp made it necessary to recreate virtually every frame. To simplify the modeling and reduce the amount of work, the students therefore left the steel cable grids as simple 3D bodies, which they only re-textured later in Lumion. The 3D representation of the railing was ultimately used only for details and cutouts, converting it into a line representation using the "hidden" calculation.

To generate a more realistic impression of the bridge, the 3D model was exported to Lumion, where it was textured and post-processed with materials and pre-sets. For a smooth workflow, the team used line colors so that 3D bodies with the same texture also received the same line color. Thanks to the SKP format and the live interface to ALLPLAN, data could be exchanged quickly and easily between the programs at any time. Buildings in the immediate vicinity as well as individual open space elements such as walls were also modeled in ALLPLAN using free 3D bodies and exported to Lumion.