After about 100 printing hours and an eight-month construction process, Germany's first completely 3D-printed single-family house is ready.

The time has come: Germany's first 3D-printed single-family house (we reported) is finished and is now visible to all eyes in Beckum, North Rhine-Westphalia. According to architect Waldemar Korte from MENSE-KORTE ingenieure + architekten, the pure printing process took just about 100 hours, or around twelve and a half working days. Not a bad value for around 160 square metres of usable space. The entire construction process of the pioneering project on German soil took about eight months. The building was designed with ALLPLAN.

Gantry robots and groundbreaking "ink"

In addition to Waldemar Korte and the HOUS3DRUCK building owners' association, which he founded, the project partners PERI and HeidelbergCement were particularly responsible for the success of the project. As the executing company, PERI took care of the execution, i.e. the actual printing, with a huge gantry robot. HeidelbergCement, in turn, together with its subsidiary italcementi, supplied the groundbreaking "ink", so to speak: a special concrete for the shuttering-free application called i.tech 3D.

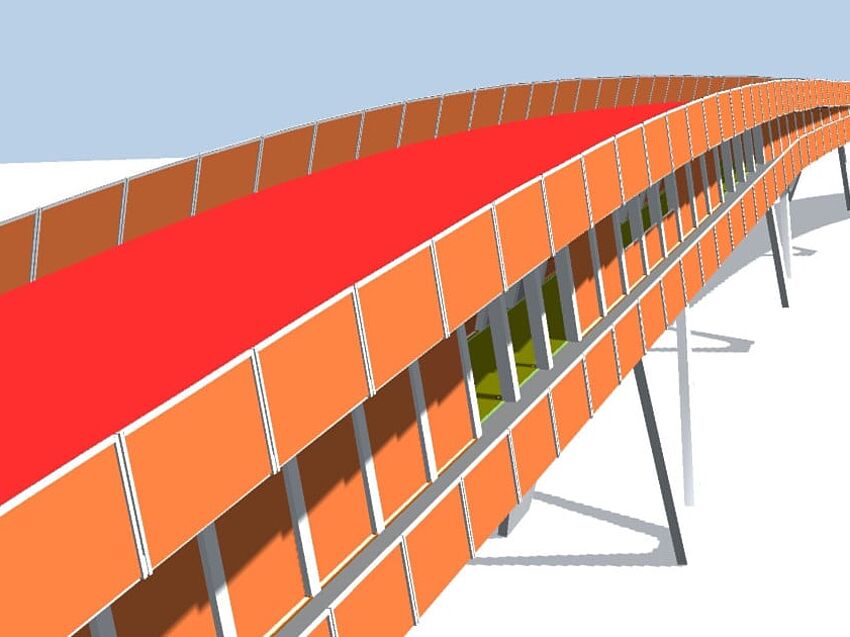

Round "corners" and optical side effect

The additive process makes shapes possible that could only be realised with great effort using classic construction methods. In the case of the house in Beckum, for example, this applies to the round "corners". The grooved façade clearly shows the different layers and thus its origin in 3D printing, which created it. An optical side effect that the building can certainly wear with pride. And who knows: perhaps this special feature will soon be seen more often in Germany.