As technology continues to disrupt the construction industry, embracing innovation is no longer optional – it’s essential. Consequently, Building Information Modeling (BIM) is increasingly being adopted for planning numerous construction activities. In particular, formwork planning has emerged as an area where the incorporation of BIM offers significant advantages. Beyond just cost efficiencies, construction firms and general contractors are recognizing the extensive advantages of applying BIM in formwork preparation.

Taking an Innovative Approach

When it comes to in-situ concrete, the dynamics are changing. Whether for rental or ownership, there’s an increasing preference for internal formwork planning, fueled by the escalating costs of outsourcing formwork planning to original equipment manufacturers (OEMs). Many OEMs levy hefty charges, sometimes reaching 500 € for a single formwork plan. To reduce this additional pressure on project finances, some companies have turned to manual planning utilizing manufacturer-defined geometries. However, while this method offers basic visualization and plan creation, it lacks advanced intelligence.

Yet there are some pioneering construction companies who are finding alternative solutions to this problem. By incorporating BIM models into formwork planning, they’re reclaiming control over their projects and budgets, especially for complex formwork activities. At the same time, they are also increasing their capacity for handling larger, more intricate projects. The office building “Roche New Office Building 2” in Basel – built by ARGE Marti Roche Bau 2 (Marti AG Zurich/Basel) – stands as testament, where the project not only adhered to its timeline but finished ahead of schedule.

Options for Efficient Formwork Design

When it comes to planning formwork, there are essentially three approaches, each with distinct advantages and disadvantages:

1. Engaging Rental Firms or OEMs: This route tends to be costly and can reduce the options available, as solutions are confined to the offerings of that particular manufacturer or rental firm. However, for busy teams, outsourcing offers an efficient way to ensure progress – and pace – is maintained on a project.

2. Utilizing OEM-specific Tools: A multitude of OEMs provide planning tools tailored for their own systems and designated CAD software, which can improve the efficiency of the planning. On the other hand, these tools bind users to particular manufacturers and their workflows.

3. Manual Methods: For smaller projects, manual methods using customized blocks or drawing on past expertise can be used. Although this method offers flexibility, it can come up short in terms of efficiency and intelligence.

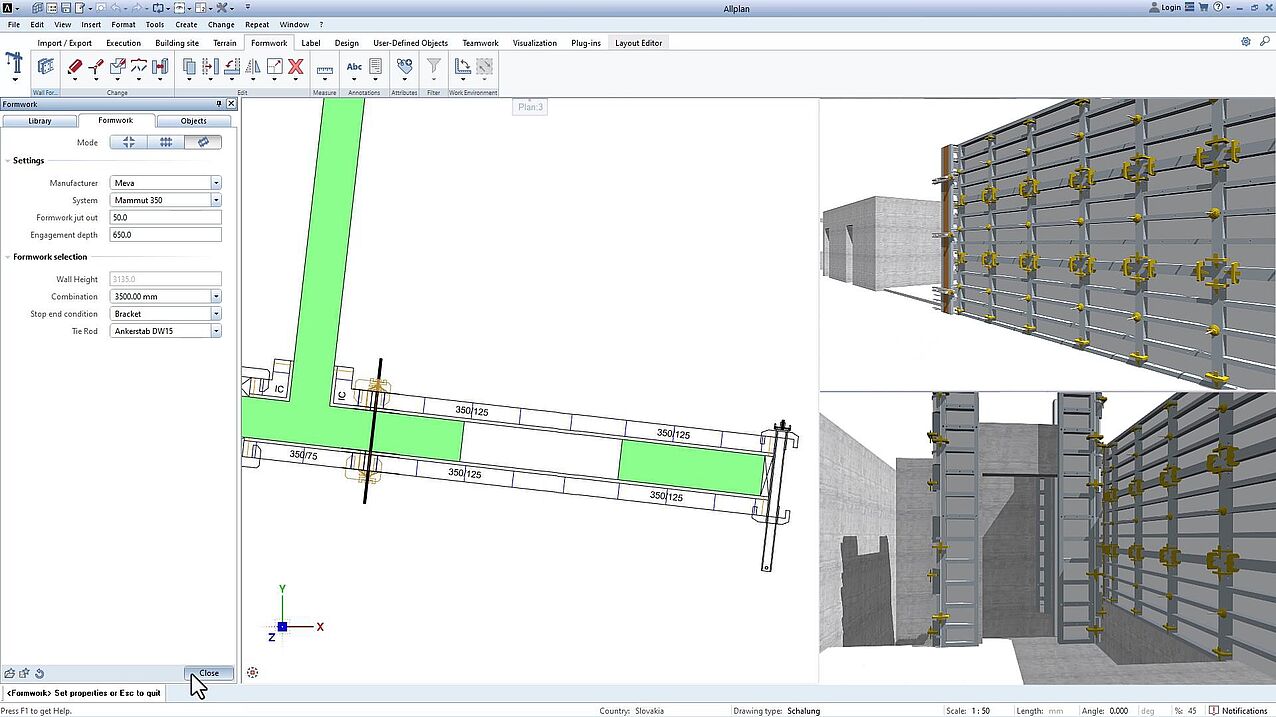

However, there is a fourth option: using ALLPLAN’s formwork planning feature. This software provides users with the tools they need to design the building formwork, for much less than an external formwork planner. What’s more, the benefits extend well beyond just cost savings.

Formwork Planning with BIM in Practice

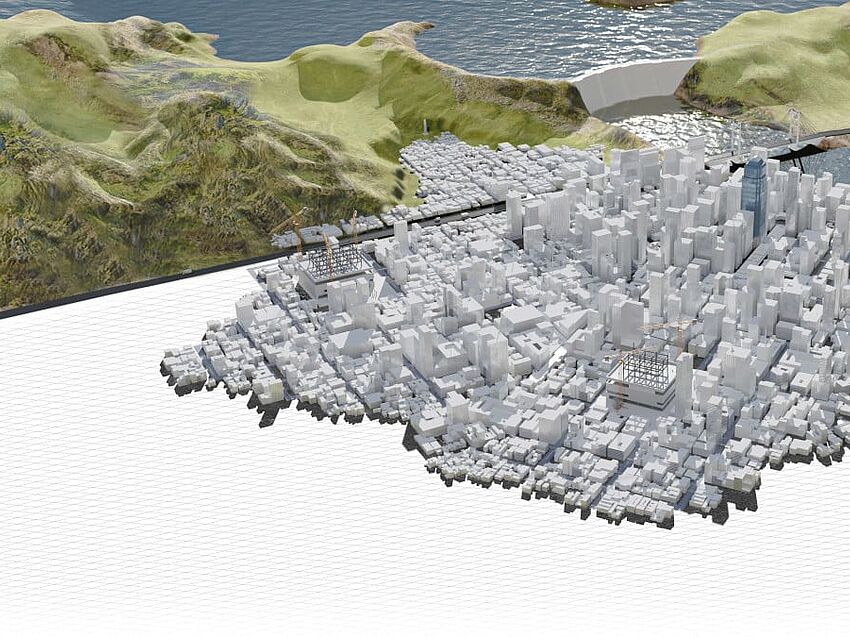

To understand the advantages that BIM offers for formwork planning, consider the following use case. After successfully winning a tender for a building project, the construction phase requires in-depth planning. Central to this planning is a 3D BIM model, which is either supplied during the tender phase or crafted internally. This model serves several purposes. Firstly, it’s the basis for the quantity estimation and cost planning during the tender phase. Afterwards, it can be used for the formwork planning, including planning specific activities or simulating the construction execution.

For the formwork planning, the building is divided into distinct segments, taking the construction schedule as well as the labor and resources required into account. This methodology maximizes operational effectiveness and resource allocation.

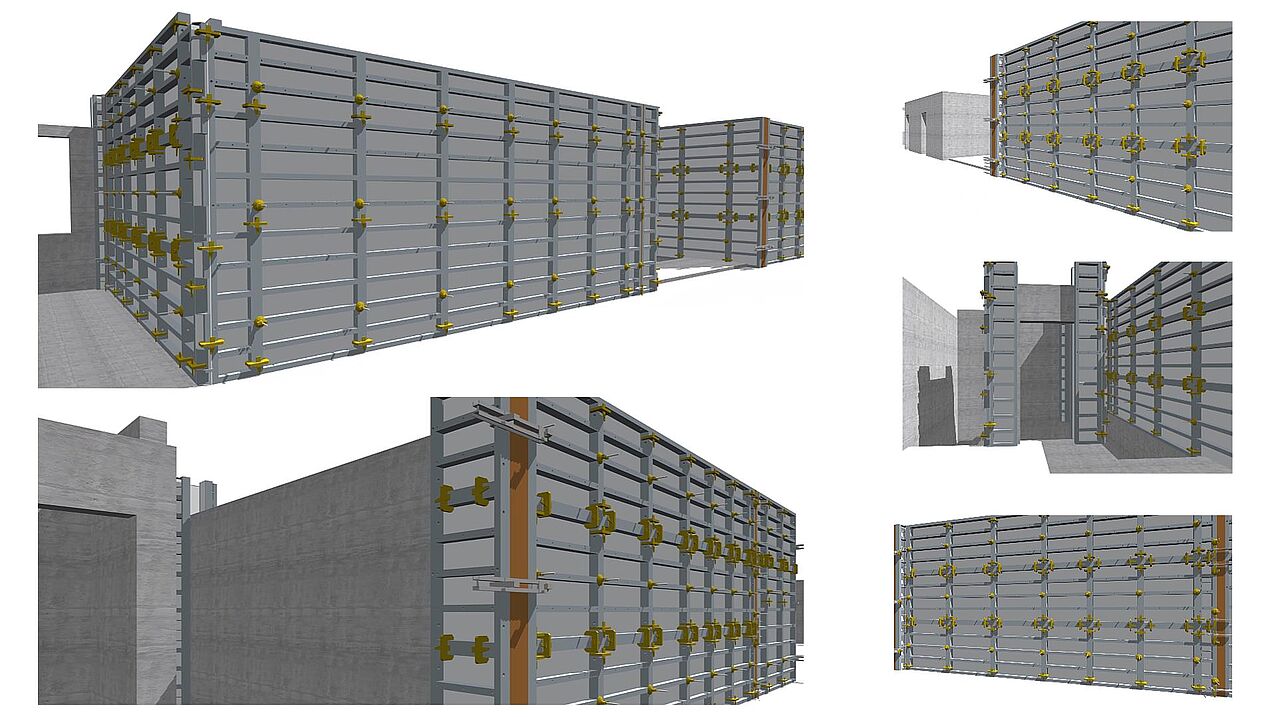

Next, a step-by-step plan for the formwork components is created. With ALLPLAN’s formwork planning tools, engineers can optimize utilization of formwork components over time, pinpoint and solve potential safety hazards and resolve clashes created by formwork components in crowded areas of a project. By assigning a time attribute to the formwork elements, it is also possible to create reports of the maximum quantities of formwork elements that must be ordered and delivered at various points in time.

The Advent of BIM-Integrated Formwork Planning

Technology is developing at a rapid pace, and as a result, formwork planning will continue to become increasingly efficient. ALLPLAN is dedicated to supporting the entire Design to Build process, with solutions that increase efficiency across the project life cycle. The latest release offers advanced workflows for rapid construction site design, enabling formwork – as well as other operations, such as cranes and groundworks – to be meticulously planned and executed.

In summary, integrating a BIM model into formwork planning isn’t just about cost-effectiveness. It’s a forward-thinking approach, enabling construction companies and main contractors to control their projects effectively, ensure operational efficiency, and drive innovation. With the construction industry evolving rapidly, capitalizing on BIM-centric formwork planning is a forward-thinking step that will help to set new benchmarks of success in the sector.

>> You want to know more about formwork? Then join us in our free webinar "Formwork planning with BIM models: Increasing efficiency for construction companies and general contractors" on November 9, 2023. <<

Isn't it time you experienced the future of construction design? Explore what ALLPLAN 2024 has to offer and take your projects to the next level with a free, 14-day trial.

{}