The 20 most expensive buildings in the world: from super mosques to luxury casinos

The world's first house made entirely of carbon concrete is currently being built in Dresden. It is intended to lay the foundations for replacing reinforced concrete to a large extent.

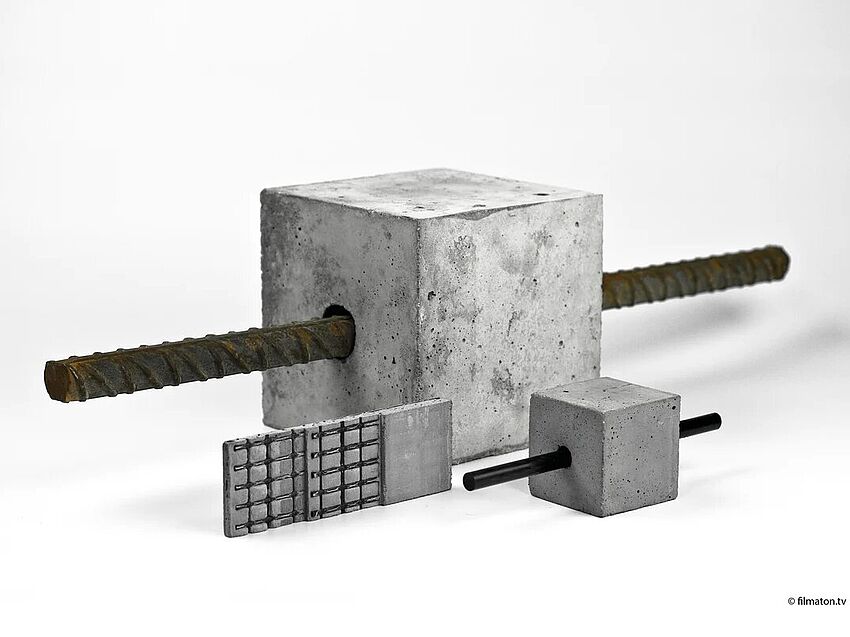

Due to its high tensile and compressive strength, reinforced concrete is indispensable in many areas of construction, especially in bridge building. But the composite material is also a problem child, devouring enormous resources and producing huge CO2 emissions. On top of that, its service life is severely limited at 40 to 80 years. For these reasons, the "C3 - CARBON CONCRETE COMPOSITE" consortium is pursuing the goal of replacing the supposedly irreplaceable building material as far as possible with a more sustainable alternative in a research project funded with 45 million euros: Carbon concrete. As part of this ten-year project, the world's first house made entirely of carbon concrete is currently being built in Dresden.

CUBE = TWIST + BOX

CUBE, as it is called, is the largest sub-project of the C3 project. The resulting house will be 40 meters long, 7.2 meters wide and 6.9 meters high, with a gross floor area of 220 square meters. The building consists of two elements: 1. TWIST - a free form of two opposite shells, each twisting into a roof starting as a wall - and 2. BOX - a cube that will find its place under this winding wall-ceiling. The functions planned include a presentation room for around 20 people, laboratories and test and technical rooms relating to carbon concrete. The BOX section in particular will be used for long-term monitoring of various components made of the material.

Innovative strength from eastern Germany

The subproject is a showcase project for innovative strength from eastern Germany: The Dresden State Enterprise Saxon Real Estate and Construction Management is making the site available for a provisional period of ten years. The tasks of the building owner will be taken over by the TU Dresden. Other partners in the construction project are HTWK Leipzig, AIB GmbH (Bautzen), ASSMANN Bauen + Planen (Dresden), HENN (Berlin), texton e. V. (Dresden), the Oschatz concrete plant and Bendl-HTS GmbH (Sebnitz). Planning on the demonstrator for the forward-looking construction method began in September 2017. Completion was actually scheduled for spring 2021, but will now probably not take place until a year later due to the pandemic.

Compelling arguments for carbon concrete

The C3 consortium, which consists of more than 160 partners from science and research, is pursuing the overall goal of developing the basis for replacing at least 20 percent of steel reinforcement in new buildings with carbon within ten years. The arguments for this replacement are compelling: Carbon concrete not only has a service life of over 200 years. Since the textile reinforcement does not rust, the concrete layers do not have to be nearly as thick, which makes more filigree structures possible, saves material and the energy required for production, and prevents associated CO2 emissions. The project also aims to establish the basis for demolition, dismantling of carbon concrete structures and recycling of the building material.

At present, carbon fibers are still mostly produced from the crude oil product acrylonitrile. However, an EU-funded research consortium called LIBRE has already developed a more environmentally friendly alternative based on lignin.