ALLPLAN 2025-1: Smarter Workflows and Stronger Collaboration

Creating 3D models has long been the province of architects rather than engineers. But with the advanced 3D modeling tools available, civil and structural engineers can now start reaping the benefits of 3D designs. Whether you want to create structurally ambitious buildings or design complex concrete reinforcement, the possibilities offered by 3D modeling are endless.

How Does 3D Modeling Software Help Civil and Structural Engineers?

Advanced 3D modeling software gives civil and structural engineers a way to work more accurately, efficiently, and cost-effectively than traditional 2D design methods. This is particularly true on complex projects, where errors can easily creep into the design. With 3D modeling, drawings and quantities are created as a by-product of the model, making updates and changes quicker, easier, and more accurate. Collision checks can help detect clashes between components for higher quality designs.

In addition, designing and detailing concrete reinforcement using intelligent modeling tools drastically reduces the time needed for reinforcement design. Even bar bending schedules – which are typically painstakingly manually created in Excel – are auto-generated from the model at the click of a button.

How Are Other Civil and Structural Engineers Using 3D Modeling Tools?

Inspired by the modeling work of architects, these civil and structural engineers turned to 3D modeling for their projects with impressive results. Here are a few examples.

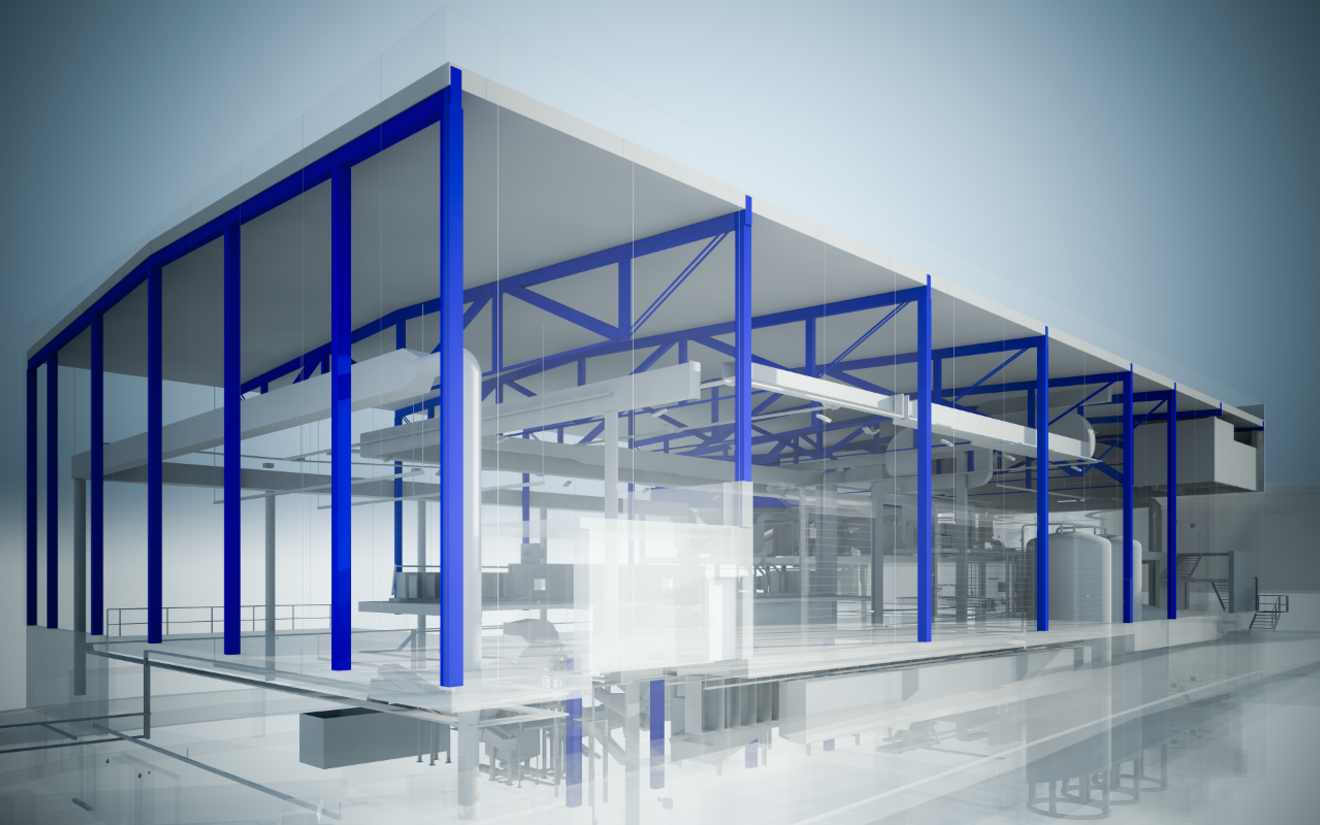

Biomass Treatment Plant, Switzerland

The new biomass receiving and treatment plant needed to align with the existing structures present on the site, while also coordinating the operational requirements of the receiving area and the treatment area. Using a 3D model allowed the existing buildings to be modeled to ensure a collision-free design, while also helping to achieve the architect’s vision of a large, 62.5m by 36m hall that had no columns. 3D modeling software allowed the engineers to meet all the requirements while also providing the client with a model they could use for facilities management.

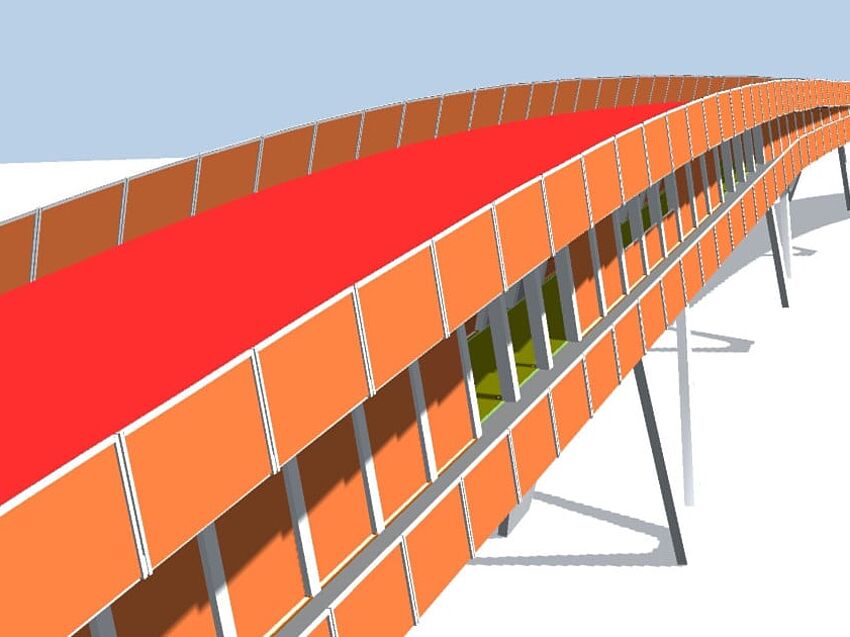

Katwijk Pumping Station, Netherlands

This project was particularly complex due to the wide range of shapes used – trapezoidal exterior walls, a cylinder-shaped trough, round flow openings, and elliptical platforms for cleaning cranes – as well as the existing pumping station. These conditions meant being able to design in 3D helped the engineers visualize the building accurately while also identifying collisions before work started on site. In addition, several designers were working on the same model simultaneously, so everyone always had access to the latest information.

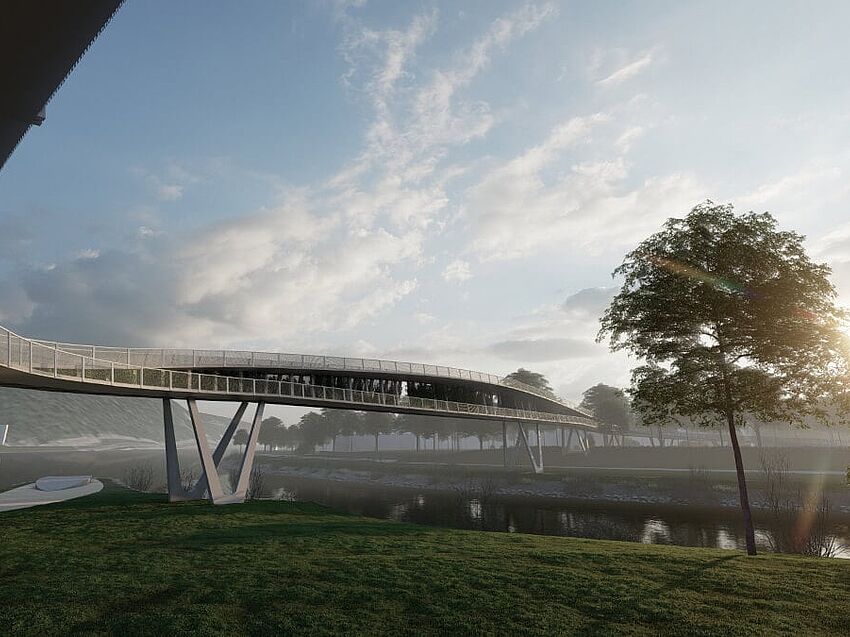

Tamina Bridge, Switzerland

As the largest arched bridge in Switzerland, this structure features an arched span of 265m, a superstructure length of 417m, and a height of 220m. Early in the project, extensive designs of the pre-stressed element guides and reinforcement were required to demonstrate that the design could be built, while also ensuring that those tendering for the works were aware of the challenging construction conditions. A high-level of detail was able to be designed early on thanks to 3D modeling tools, while also making the reinforcement design more efficient and error-free. This bridge has also received international awards for its design team.

High Complexity Needs 3D Models

Complex designs combined with increasing time and cost pressures means that civil and structural engineers need to deliver error-free designs more efficiently. 3D modeling software offers civil and structural engineers a way to create ambitious designs easier, quicker, and more accurately than with 2D CAD. For more inspiration, see our Engineering References page for more 3D engineering projects. Alternatively, why not try a free 30-day trial of ALLPLAN Engineering to see how your team can start benefiting from 3D modeling software.