The new Çetin Dam and Hydro-Electric Power Plant (HEPP), built on the Botan Stream of the Tigris River in Turkey, was completed in April 2020 and began producing electricity the following month. At 165m tall and a volume of over 4.7 million cubic meters, this massive roller compacted concrete (RCC) dam is the largest of its type in Europe. With an annual energy generation of 1.174,74 GWh, the new dam will generate enough energy to supply the needs of six provinces the size of Siirt, one of the local cities the dam will power. Designing this enormous structure was a unique challenge for the engineers, Su-Yapı, which they overcame with the help of ALLPLAN.

A Challenging Project

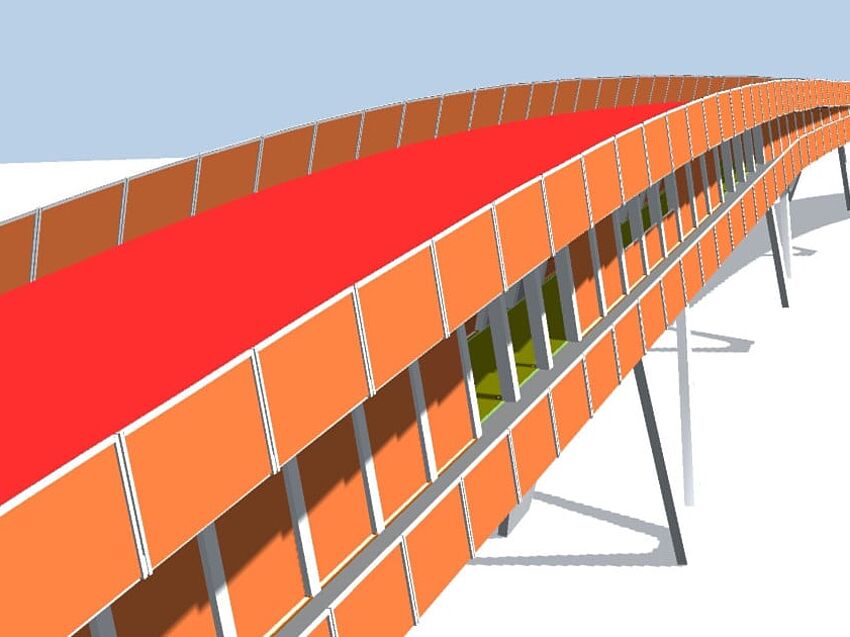

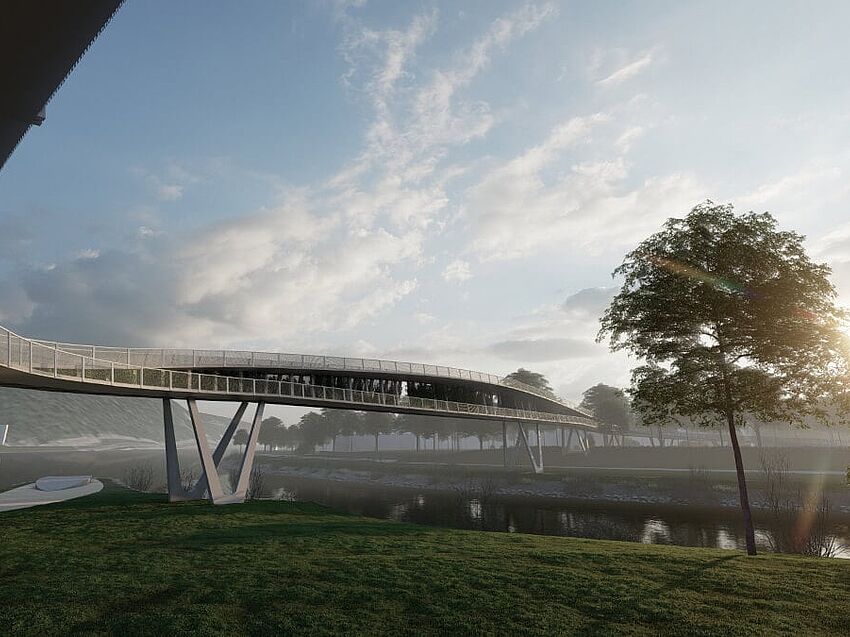

The dam needed to create a 615 million cubic meter reservoir in order to generate the power required. As well as the dam itself, the engineers needed to design four vertical-axis Francis turbine generators, of which three would have a 135MW capacity and the fourth would have 15MW. In addition, the nearby village access road needed to be relocated to accommodate the new reservoir. However, the only available option was to build a new highway and bridge, as the terrain and geology in this area was difficult to build upon. Combined with the tight delivery timescales, this presented many challenges for the team at Su-Yapı.

Designing at Pace

Designing a complex project with many different aspects such as landscaping, dam and power plant construction, and a new bridge and highway meant that many hundreds of drawings were required. At the same time, the design had to be accurate and contain as few errors as possible, particularly as there was little room in the schedule for any re-work. In addition, the team needed a way to quickly and easily approve submittals during the construction phase and provide any design support needed.

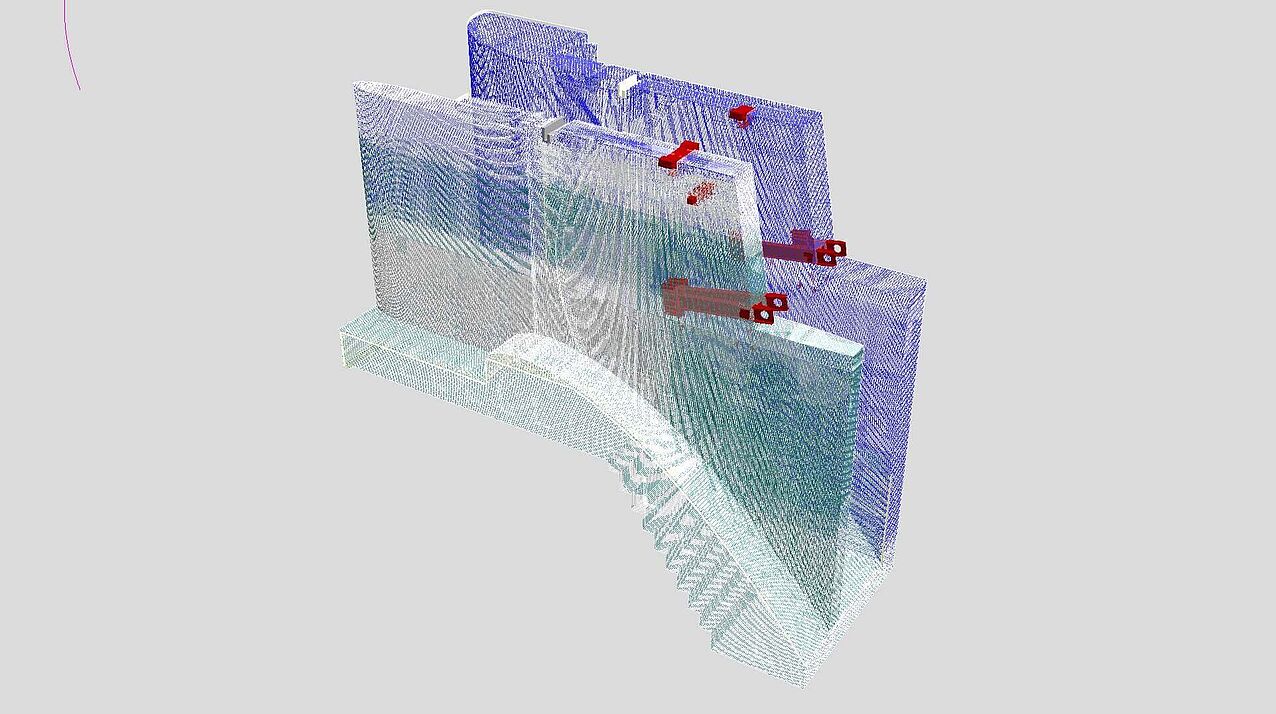

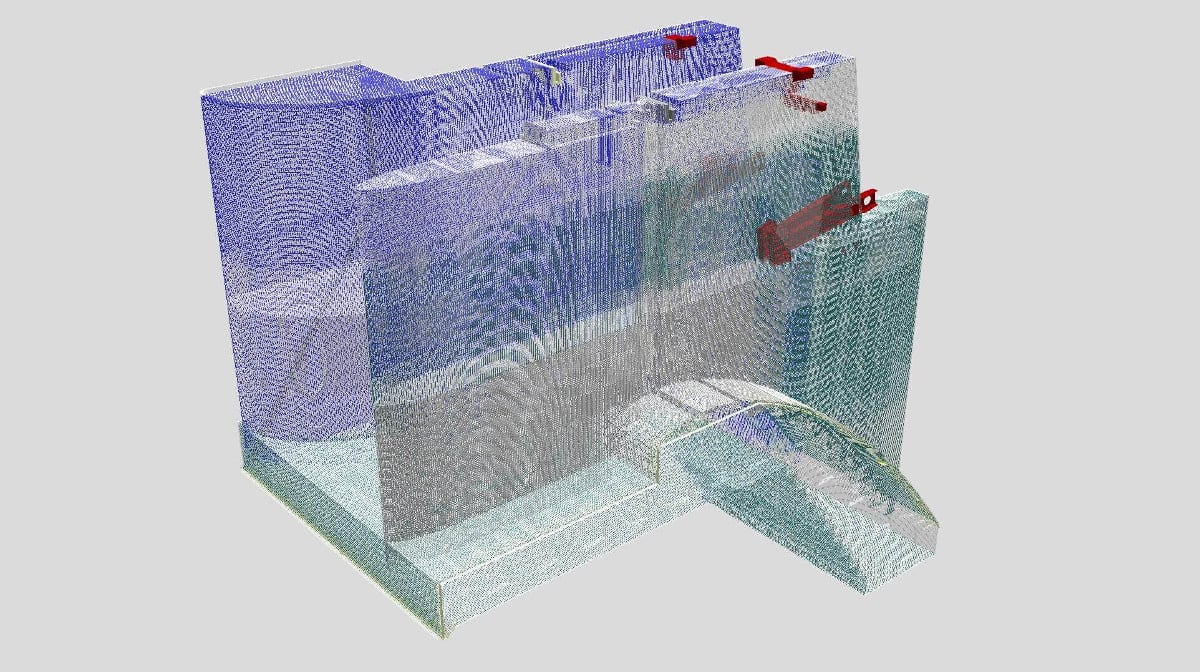

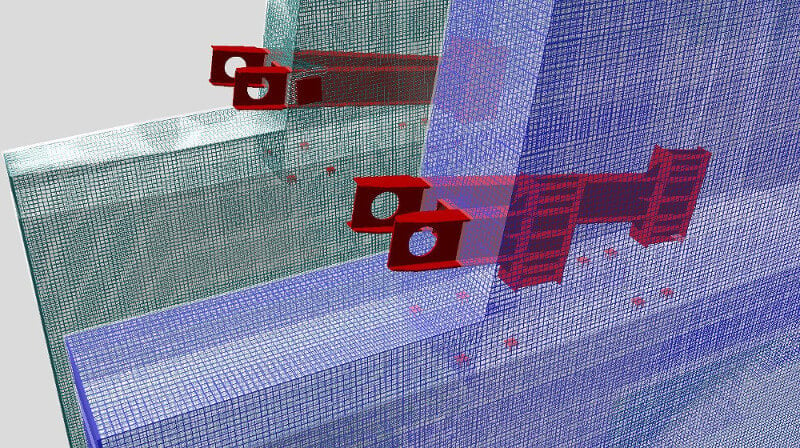

3D CAD Software Made for Engineers

The unique interface of ALLPLAN – which enables engineers to work in 2D or 3D according to their preference – assisted with the rapid drawing production that was required in order to achieve the client’s deadlines. By creating the model in 3D (even if working in 2D), sections, views, and details could be easily extracted from the model, rather than drawing each detail separately. Not only did this significantly accelerate the drawing creation , but it also made updates and changes much faster, as each view would update automatically as the model changed. This meant more could be achieved with fewer staff allocated to the project. With the included data exchange interfaces and openBIM support, exchanging information with the contractors involved – such as for the submittals approval process – was simple and straightforward. Overall, the project was completed swiftly and smoothly, with the residents of the area now benefitting from renewable electricity after just three years of construction.