Future-proof multi-generational living in a courtyard development

Concrete has been the backbone of our built environment for over a century, forming the foundations of our cities, bridges, and vital infrastructure. Traditionally, inspecting the health of these massive concrete structures has been a complex and sometimes destructive process, relying on drilling core samples and visual assessments. However, a new frontier in non-destructive testing is emerging, harnessing a surprising source: cosmic rays. This cutting-edge method by a company called GScan promises to revolutionize how we assess and maintain our concrete infrastructure, ensuring its longevity and safety without the need for invasive techniques. Welcome to the future of concrete inspection with muon technology.

The Role of Muons in Concrete Inspection

Muons, energetic particles originating from cosmic ray collisions with our atmosphere, are constantly bombarding the Earth's surface, with thousands passing through our bodies and buildings every second. Invisible to the naked eye, these particles hold the key to unveiling the secrets hidden within concrete structures.

The concept of using muons for scanning large structures dates back to the 1950s, when particle physicists first applied them to mining sites. Initial attempts in the 1960s and 70s, such as scanning Egypt's pyramids, produced low-resolution images. The breakthrough came in the early 2000s with the development of muon scattering tomography by physicists from Los Alamos, which offers submillimeter resolution 3D images and chemical composition details. Now, after a couple more decades of refinement, this technology is revolutionizing structural inspection.

A Structural Engineer’s Dream

GScan, a pioneering deep-tech company, has developed a cutting-edge technology that leverages muons to peer deep inside concrete structures. By deploying sophisticated detectors and advanced AI analysis, GScan can track muons with remarkable precision. This allows them to create detailed 3D models that reveal the internal composition of concrete, including the presence of cracks, voids, and deterioration in steel reinforcement cages. The technology’s ability to provide accurate, non-invasive inspections offers invaluable insights for engineers and architects, enabling them to assess the integrity of critical structures efficiently and safely, without the need for destructive testing methods.

GScan’s technology offers unparalleled versatility, capable of scanning elements ranging from millimeters to hundreds of meters. It can determine risks related to chemical composition, such as corrosion from concrete passivation loss or high chloride levels. The ability to detect discontinuities in materials, reinforcing and prestressing steel, allows for identification of delamination, corrosion, or breakages. Furthermore, it can penetrate shielded materials and covered elements, such as reinforcements behind metal facades, plasterboards, insulation, and thick paint. The technology is 100% safe for humans, fully passive, and detects only natural radiation. It is robust, unaffected by environmental variables like humidity or moisture, and eliminates subjectivity from measurements and interpretation. Versatile enough to measure all types of materials and defects, including wood, plastic, and composites, the outputs integrate seamlessly into general coordinate systems through 3D images created with muon tomography. This enables automatic BIM model generation of existing structures, enhancing the reliability of decision-making processes.

Case Study: Structures Moonshot

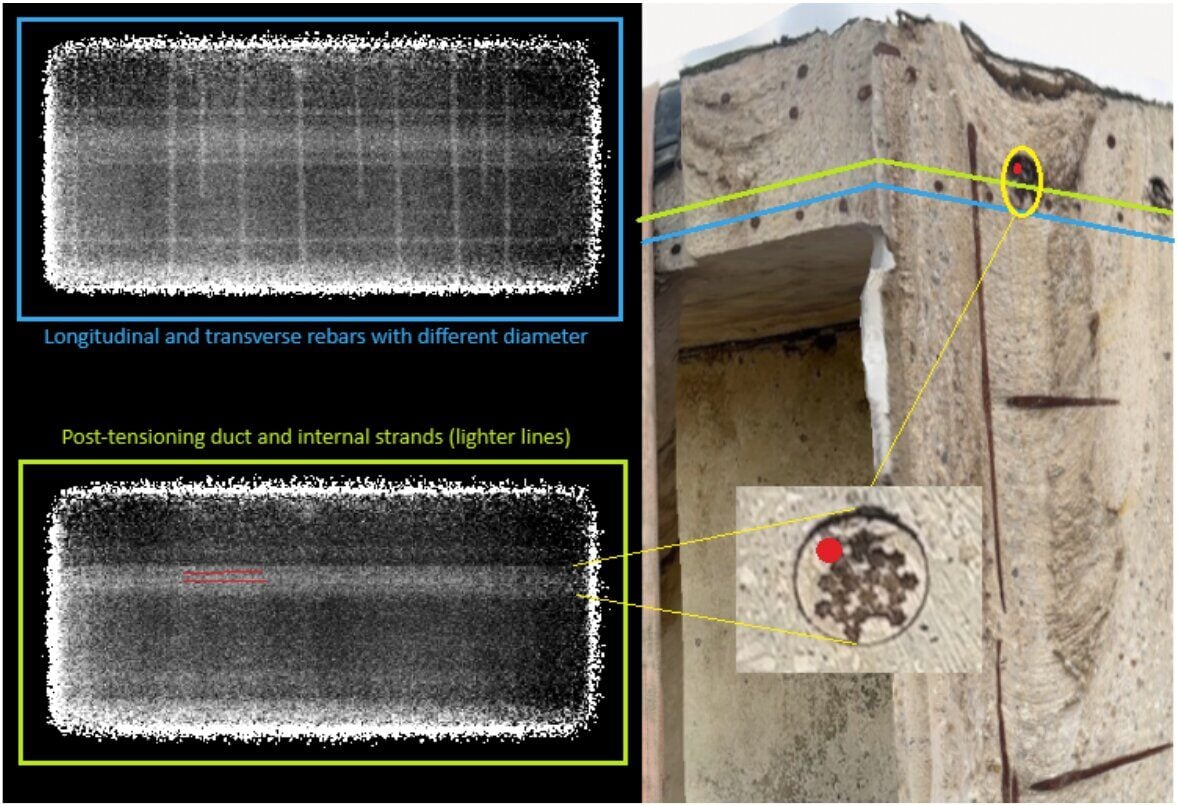

GScan's collaboration with UK National Highways on the "Structures Moonshot" project showcases the real-world application of their technology. This project focused on a critical piece of infrastructure: post-tensioned concrete bridges, which rely on high-strength steel tendons for structural integrity.

Traditional inspection methods for these tendons are often time-consuming and expensive. By deploying GScan's muon flux scanning technology, the project precisely mapped the location and orientation of the tendons and assessed the condition of the ducts. The results were impressive, providing infrastructure managers with detailed insights for informed maintenance and repair decisions, enhancing the safety and longevity of the bridge.

The Diverse Applications of Muon Scanning

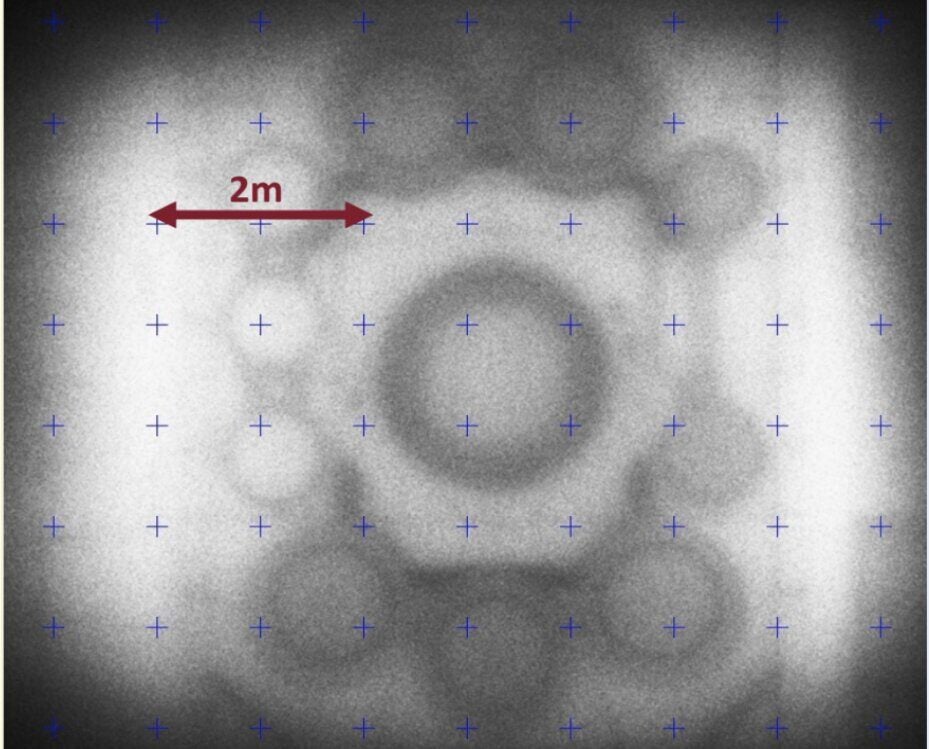

The potential applications of GScan's technology extend far beyond bridges and reinforced concrete. This innovative method can be used to inspect various structures, including buildings, tunnels, dams, and even nuclear power plants. Versatility of the muon technology allows it to assess the condition of other structural materials like steel, masonry or also timber. For instance, assessing the integrity of a building column without drilling or disrupting tenants becomes feasible. In 2023, GScan applied their technology to scan old abandoned military nuclear reactors in Paldiski, Estonia. The results were remarkable, producing 3D images with 1cm resolution, far exceeding expectations. This high level of detail allows for more efficient and safer decommissioning plans, demonstrating the technology's versatility and transformative potential across different sectors.

Future Prospects and Impact

GScan's technology represents a significant leap forward in non-destructive assessment, opening up numerous future applications and innovations. As this technology evolves, it promises to enhance infrastructure management by providing precise, reliable data. Experts like Ernst Niederleithinger, Head of Non-Destructive Testing in Civil Engineering at BAM, have noted the technology's potential, with results exceeding expectations. The ability to integrate outputs into BIM models further strengthens decision-making processes.

As GScan continues to refine its muon technology, we can anticipate broader adoption, leading to improved safety, reduced costs, and more sustainable maintenance practices in infrastructure management globally.