Better Precast Girder Bridge Design with ALLPLAN: A Complete Workflow Solution

For the analysis and seismic retrofitting of a 1960s viaduct, the Fanigliulo engineering firm used ALLPLAN Bridge. They experienced several benefits, including faster design times (50 percent reduction), improved accuracy, and integrated workflows.

Project Background

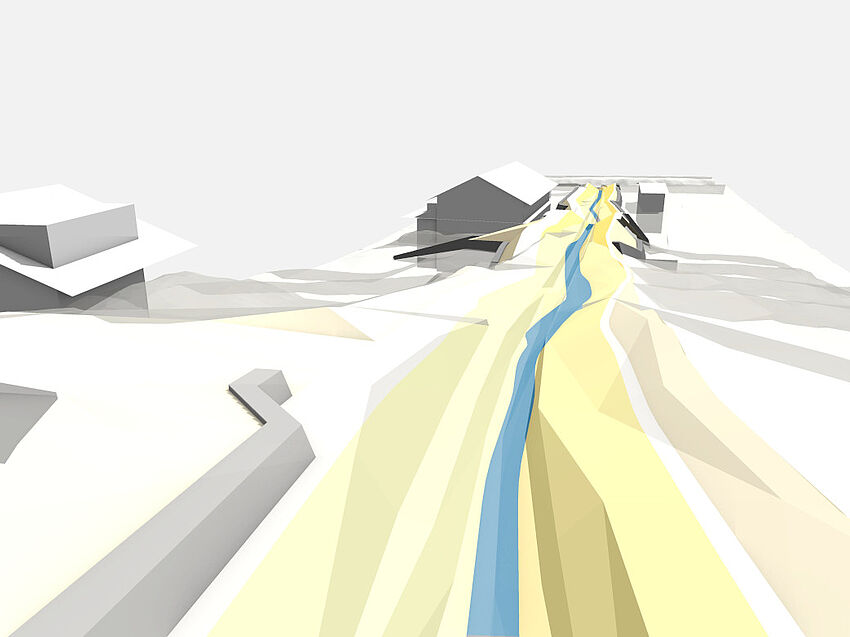

The Cernicchiara Viaduct, located at the beginning of the A2 on the Salerno-Reggio Calabria section of the highway, dates back to the 1960s. Even to this day, it plays a strategic role in the road connection network of the city of Salerno, helping to channel heavy vehicular traffic towards the port and logistics infrastructure and light vehicular traffic towards the city center.

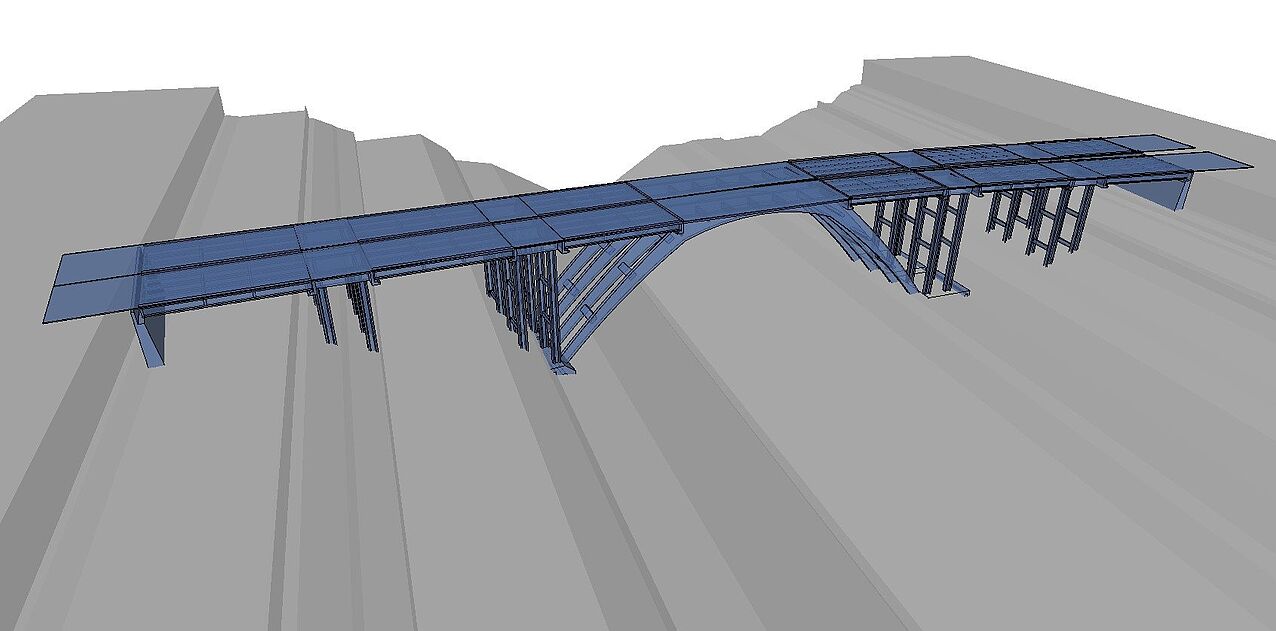

The viaduct, which is 142 meters long, has six spans and a central arch of 80 meters. Each span is set up as a beam supported at the ends, represented by the piers, while the central span is an arch embedded at the base. The piers are of the frame type in two directions. Thus, each pier consists of four columns connected in the direction of the transverse axis of the viaduct by horizontal beams arranged on two levels.

The entire viaduct was made of cast-in-place reinforced concrete and is a true iconic example of viaducts on the Italian highway network. Years of use and regulatory updates to anti-seismic standards have made it necessary for the structure to be checked and subsequently seismically upgraded. ANAS, the infrastructure's managing body, turned to Valori S.c.a r.l. Consorzio Stabile and the engineering firm Fanigliulo to carry out the verification and adaptation activities.

The Challenge: Rapid Seismic Verification With Minimal Traffic Disruption

Following the updating of standards and safety coefficients related to seismic safety, ANAS requested timely verifications of the structural condition of the viaduct.

The verification methodology in use previously (i.e. based on allowable stresses) was replaced with ultimate limit states – a methodology which involves limit deformation between at least one of the two materials involved in the concrete, concrete and steel. The client therefore requested a verification of the viaduct's adequacy with respect to the latest industry standards and according to the latest applied methodologies.

Finally, the client also requested the creation of a BIM model of the work to record the interventions carried out and plan future maintenance. This would enable them to provide the operator with an updated and reliable representation of the infrastructure.

Given the crucial role of the viaduct in the city's traffic system, the client required that passenger inconvenience and vehicular traffic restrictions were minimized by carrying out interventions as quickly and with as little impact as possible.

Studio Fanigliulo was able to keep the viaduct in constant operation by carrying out the most disruptive maintenance work during nighttime hours.

The Solution: ALLPLAN Bridge, an Integrated 3D Design and Parametric Modeling Solution

The project as a whole involved a thorough study phase of the original documentation. This was then completed with a series of inspections on the structure, carried out thanks to a suspended scaffold that allowed the analysis of the decks and the adoption of the least invasive consolidation solution.

The structural consolidation of the Cernicchiara took place using carbon fiber reinforced polymers (CFRPs), materials derived from aeronautics that improve the mechanical performance of structural elements by increasing their ductility and durability.

By comparing the results of the structural study of the existing state with the original design results, the coefficient ζE was determined. This expresses the ratio between the seismic action that can be borne by the structure and the seismic action that a newly built structure would be able to bear, based on the criterion of ultimate limit states. Based on the results, a numerical model calculation was performed on the FEM software, Nolìàn® from Softing®.

Following the analysis of the structure, its scanning and structural calculation, a digital model of the viaduct was created in ALLPLAN Bridge, the parametric BIM solution for bridge engineering. Fanigliulo chose to use ALLPLAN's solution after carefully evaluating software offered by other brands, finding an exceptional return on investment in terms of productivity and accuracy. Another advantage was that ALLPLAN Bridge also provides excellent interoperability with other software (such as Nolìàn®).

The firm easily designed the three-dimensional model of the viaduct in ALLPLAN Bridge and, within the same platform, integrated the structural calculation model. This model thus provided the basis for planning the reinforcement and upgrades to the viaduct.

The analysis conducted on the model made it possible to identify the areas under the greatest dynamic stress and the consolidation interventions needed, which were designed and detailed with ALLPLAN Bridge. Through the use of ALLPLAN's solution, the team experienced exceptional speed and accuracy of execution – to such an extent that the verification and design of the consolidation took just 6 months instead of the estimated 12 months.

The seismic retrofitting was carried out by reinforcing the arch deck and shutters with carbon fibers and lasted for about 14 months. Therefore, the intervention as a whole took a total of 20 months between design and execution.

The Advantages of ALLPLAN Bridge: Speed, Accuracy, Integrated Management of Multiple Functions

The benefits that ALLPLAN Bridge provided were many. On the one hand, a massive increase in the speed with which design and analysis were performed, reducing the initially estimated time by 50%. On the other, the high accuracy with which the analysis and design were conducted, especially when updating the technical tables.

The updating of technical tables and their realignment – a necessary operation due to the constant changes that are required during the design phase – was handled quickly and accurately thanks to ALLPLAN Bridge. In fact, changes were made directly on the model and automatically replicated on the tables as well, eliminating the possibility of errors, omissions, and collisions.

ALLPLAN Bridge is therefore a solution that allows the designer to operate in a single environment, enabling the management of both the modeling and structural calculation phases. This avoids those discrepancies that tend to occur with the use of different software.