One building material has dominated the market for more than 100 years: reinforced concrete. However, a new composite material is emerging which has more stability, durability and lightness. It concerns carbon concrete. Researchers believe that it is set to revolutionize architecture. In our post you will find out all about this building material, what its benefits and disadvantages are and which specific building projects are planned.

The building material is manufactured in different processes

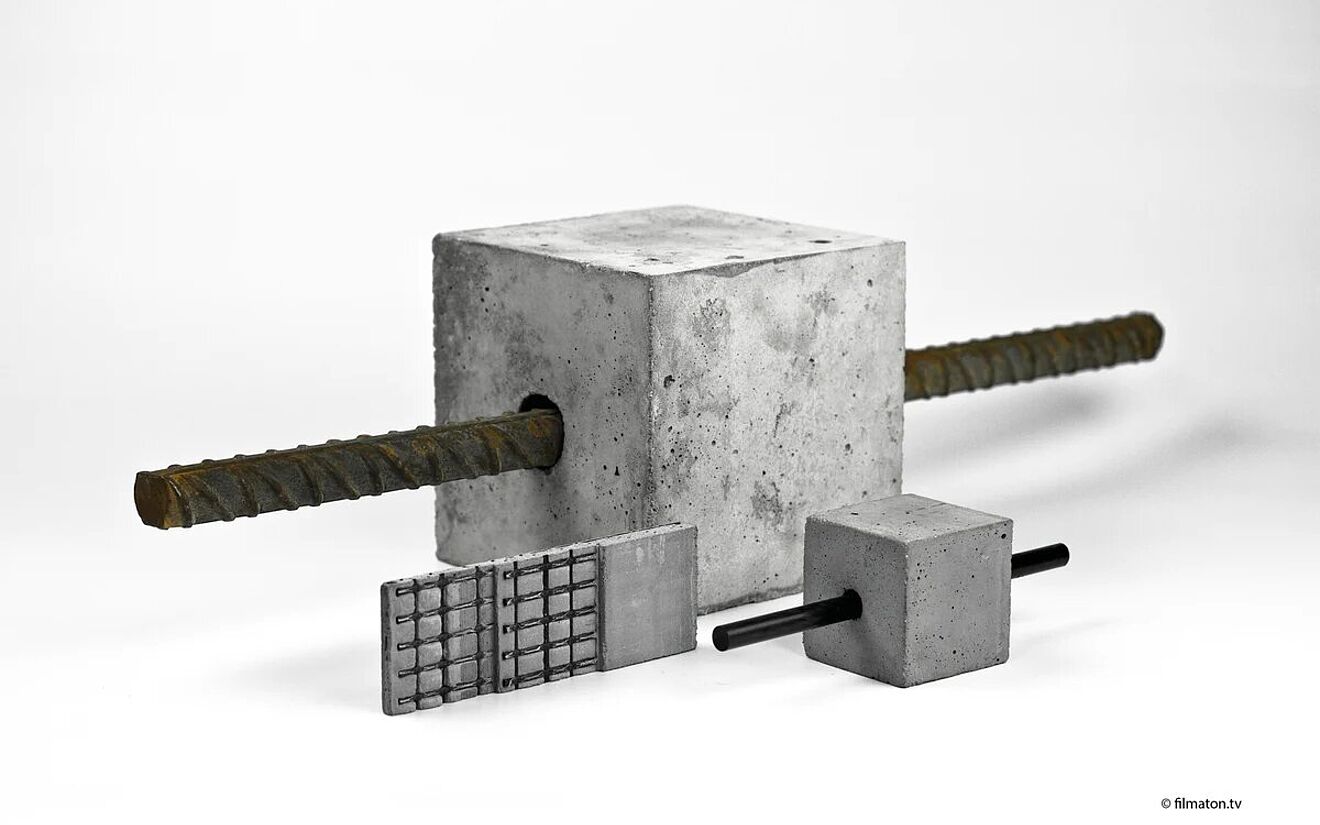

Carbon concrete is understood to mean a compound of concrete and carbon fibres. There are three processes at present:

1. Carbon fibres are added to the concrete. They are distributed wildly throughout the entire building component.

2. Grid-like textile mats made of carbon fibres are placed between fine concrete layers.

3. In the injector process devised by researchers at the University of Augsburg the fibres are sprayed systematically into the concrete. This produces a building material with extreme tensile strength.

Carbon concrete combines a range of benefits

The researchers have one vision in particular: they want to replace the reinforced concrete that has been used for more than 100 years and develop carbon concrete into the high performance building material of the future. There are plenty of good reasons to do so: in order to protect the steel from corrosion, thick concrete layers are necessary. However, the manufacture of cement not only consumes vast quantities of scare raw material sand but is also linked to high CO2 emissions. Carbon on the other hand does not corrode. The building material can be produced form any other material that contains carbon. In current projects the researchers use something called lignin for example, a waste product, which is produced in timber production.

With carbon the stability is increased by five to six times compared with reinforced steel. The life span is significantly higher too. Bridges are a good example: there are over 200,000 bridges in Germany. The majority require urgent restoration since their average life span is only around 40 to 50 years. Bridges made of textile-reinforced concrete, such as the one in Albstadt, on the other hand will be able to last for approximately 80 years without any large-scale renovations.

The costs are the biggest disadvantage of the future building material

One kilogram of reinforced concrete costs around 1 euro to produce, one kilo of carbon concrete around 20 euros. These absolute figures do not reflect the real picture however. Carbon concrete enables material savings of around 75 percent. Consequently, the total price of a construction project is reduced. In connection with the durability, stability and corrosion resistance of the material the costs balance out. In addition, researchers in Augsburg and Dresden, amongst other places, are working hard on procedures in order to make the manufacture of the composite material more economical.

They are supported in this by many partners in science and in the field. The textile-reinforced concrete network came into being in 2008 which is now a member of the wider C3 – Carbon Concrete Composite project. More than 140 research institutes, construction firms and public institutions are involved. The Federal Ministry of Education and Research finances the interdisciplinary work with a budget of 45 million euros.

The first carbon house in Germany will be built in Dresden

As early as 2019 it should be on the campus at Technical University of Dresden: the first carbon house in Germany. Building costs amounting to around 5 million euros have been scheduled for the two-storey reference project. The experimental house will not only serve for further research to the building itself but also herald in a paradigm shift in architecture. For the scientists the light, delicate and aesthetic building design is the most important aspect which carbon concrete enables. Thanks to the developed processes new architectural forms could soon begin to take shape.

Excellent prospects for the years ahead

State, the building industry and science are behind the joint project to make carbon concrete the building material of the future in the next decade. They are working tirelessly to develop a material which will transform construction in Germany, reduce costs on a lasting basis and protect precious resources.