BIM makes construction better. That's why ACS Partner AG are currently testing the next step in the digital working method with a bridge construction project in Muttenz (Switzerland): BIM2Field.

BIM2Field is the next step in handling infrastructure construction projects even more efficiently. As part of the Build the Future ALLPLAN Summit 2024, Siro Boitier from ACS Partner provided insights into the application of the BIM method on the construction site. The project engineer and BIM manager brought along the ongoing UE Grenzacherstrasse project in Muttenz (Basel-Landschaft, Switzerland) as an example. The road in question is a 490-metre-long bridge that runs over both a marshalling yard and the N02 freeway. The various sections of the structure are of different ages and need to be repaired or renewed - with varying requirements for BIM2Field.

The project is being planned by a consortium (IG AAB) consisting of ACS Partner (lead partner), Aegerter & Bosshardt and Bänziger Partner. The project team's tasks are divided into four sub-projects, which correspond to specific sections of the bridge structure. Sub-project 1 consists of the repair of the southern section of the bridge, which was already renovated in the 1990s, and is being carried out by Aegerter & Bosshardt. ACS Partner is planning sub-projects 2 (replacement of bridge RB2) and 3 (embankment and ramp). Bänziger Partner are responsible for the planning of a highway bridge (subproject 4).

Models according to the requirements for BIM2Field

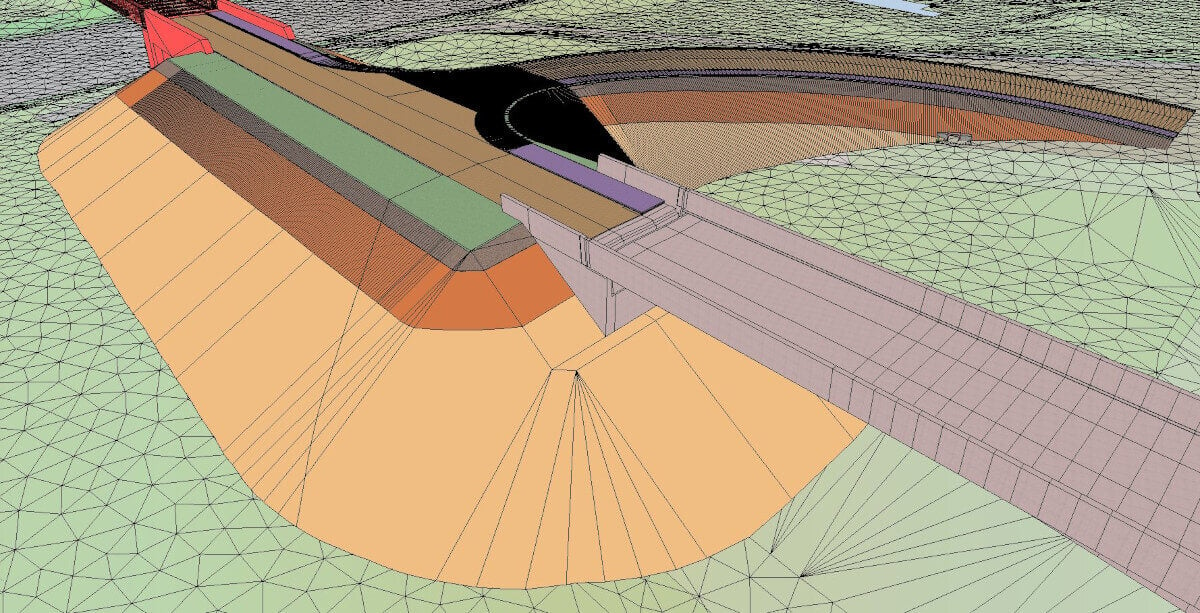

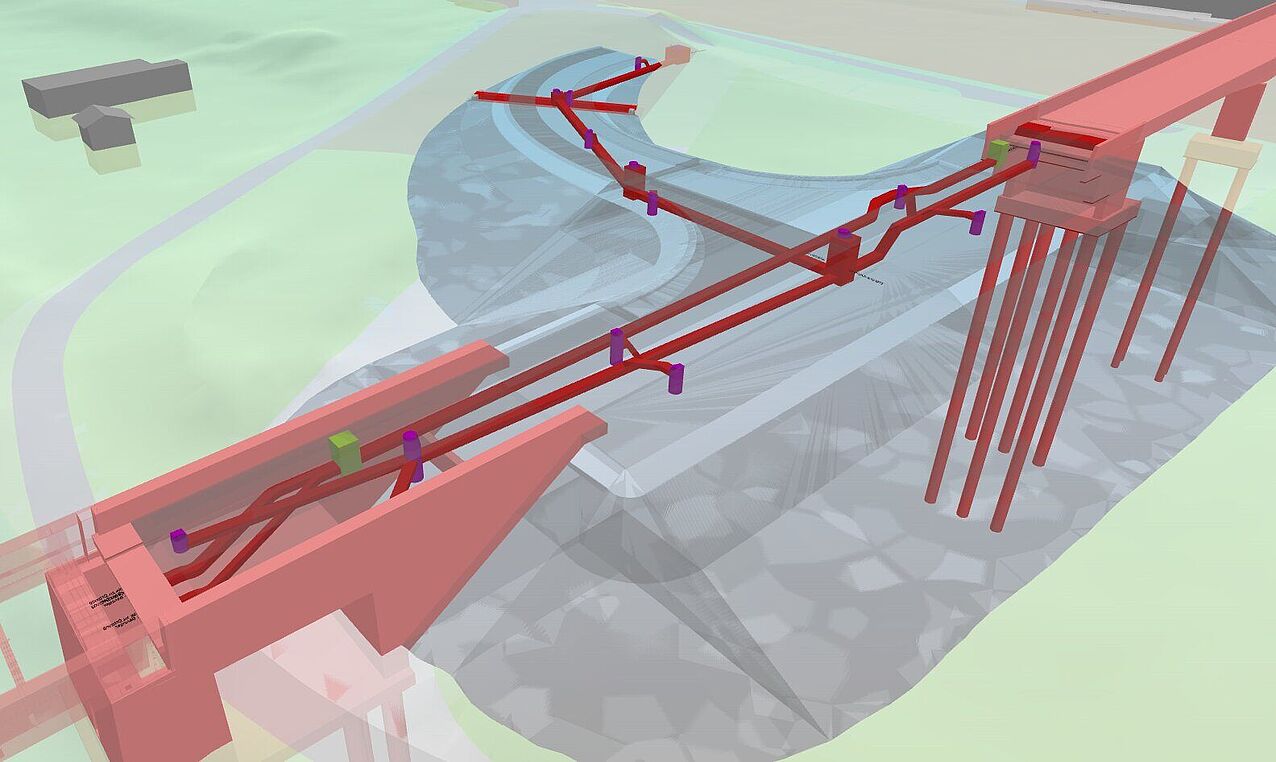

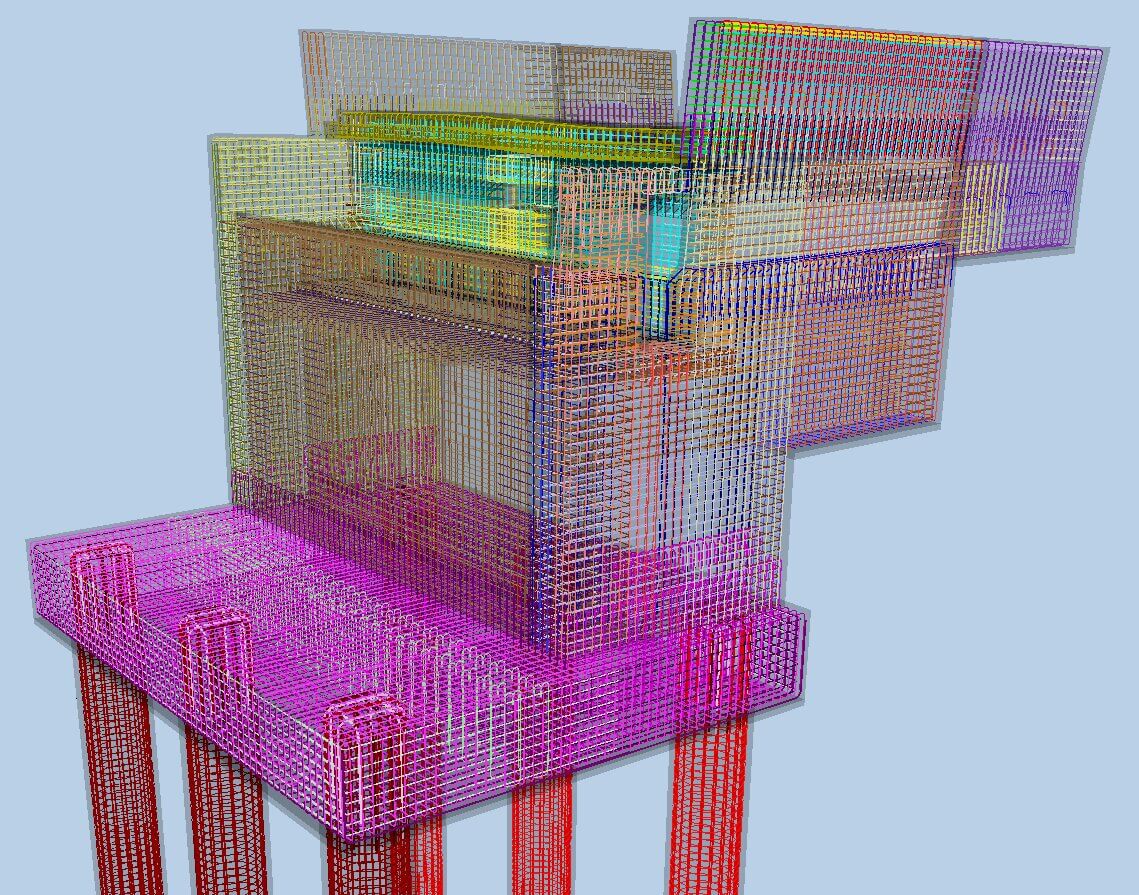

The BIM2Field design is carried out using models of the various components, which were developed according to their specific requirements. For example, the excavation pit, formwork and reinforcement were modeled for a technically necessary 40-metre-long pipeline channel. The planning of the dam structure (90 meters), for example, included an earthworks model as well as a BIM model with prefabricated concrete elements, which also included the sewer system and cable protection lines including shafts. Further BIM models were created for the road construction and the kerbstones.

Highway bridge still planned in 2D due to time constraints

The only exception to the BIM2Field approach in the construction project is sub-project 4. The highway bridge, with various concrete works on the abutments as well as a prefabricated steel bridge, was planned by Bänziger Partner exclusively in 2D, as there was not enough time for BIM modeling. The steel bridge, which is around 52 meters long and weighs around 270 tons, was already lifted into place during a night-time shutdown using a 750-ton crawler crane.

Next BIM planning steps in the project

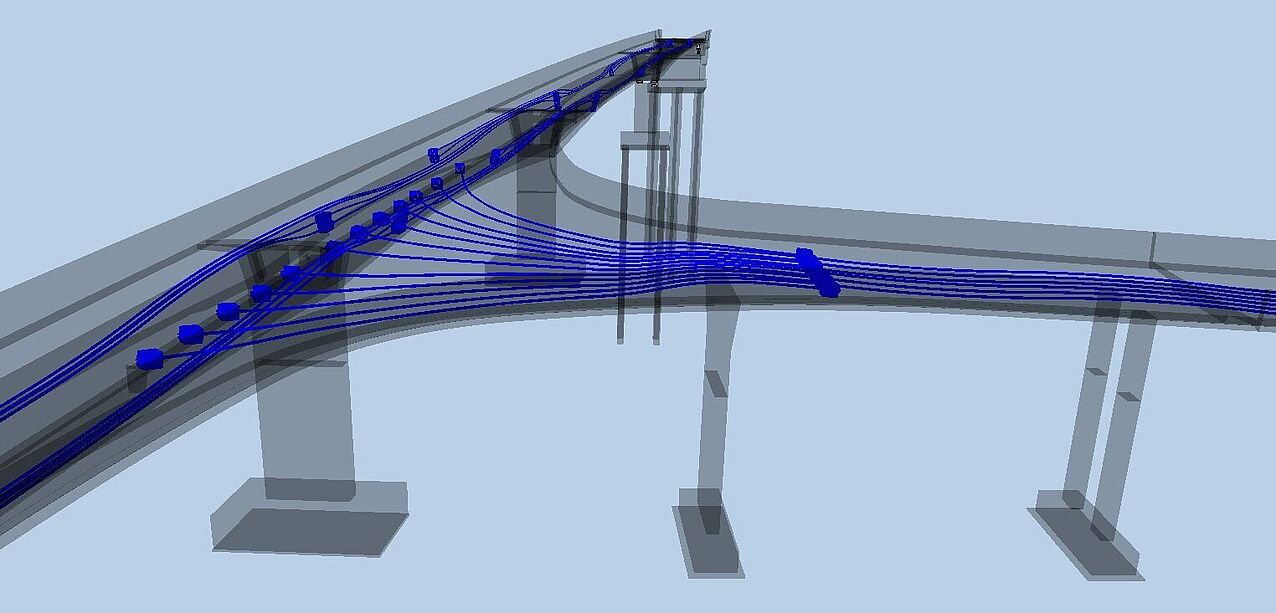

The planning for an approximately 200-metre-long road section (Hardacker-Strasse) including the sewer system in sub-project 3 is currently still outstanding. In addition, ACS partners are currently working on the bridge superstructure (TP2) including abutments and piers. In addition to a concrete model, additional surface models for hydrophobization, exposed concrete and staging are being considered. The reinforcement planning for abutments and piers has already been completed. The prestressing is currently being developed, which is geometrically very complex, particularly in the junction area between the main bridge and the ramp.

Challenges for the BIM2Field approach

The implementation of a BIM2Field approach was not without its challenges. The tendering process for both the planning and execution of the services was carried out exclusively in 2D plans. ACS Partner's proposal to switch to the BIM2Field method for execution was met with an open ear by the client SBB AG and the construction company Meier+Jäggi AG. Together, they decided to take on this forward-looking challenge.

Because the experience with BIM2Field in particular, but also with BIM models in general, was still limited among the project participants on both the planning and execution sides, a common understanding of the respective needs had to be created first. ACS partners acted according to the motto "Try your best".

Further challenges arose from the fact that certain points that would simply be neglected in 2D planning suddenly had to be solved in the model. According to Siro Boitier, solution orientation and pragmatism are required in such cases.

Solution approaches for BIM2Field

When implementing the new method, the top priorities were helpfulness, tolerance and acceptance in order to be able to apply the innovations accordingly. Special tools were therefore created for implementation, such as the BIM execution plan. This included a color table for the colors used in the model as well as an element plan in which each component is assigned an IFC identity and all required attributes are listed.

Bimplus is used as the CDE. The BIM platform is used in particular for document and model exchange as well as for issue management - both with the execution and in the test run with the client.

Better planning and the largest crawler crane in Switzerland

The bottom line so far is that, above all, better, more error-free planning has been achieved - and this has already laid the foundation for lower follow-up costs. If you would like to get an idea of the BIM2Field implementation on site, you can visit Muttenz during the weekend closure on September 14 and 15, 2024. Switzerland's largest crawler crane (1,000 tons) will then lift four 100 to 320-ton elements of the existing bridge out of the track bed.