Prof. Christian Schlüter of ACMS Architects gives an insight into possible solutions for climate-friendly and sustainable architecture.

When it comes to architecture in times of climate change, ACMS Architects plays an important role as a competent practitioner in Germany. The architectural practice from Wuppertal has already been extensively involved in the topic of resource protection for 25 years, is a founding member of the DGNB, and, in addition to its practical activities, is also active in teaching and research in this field. Prof. Christian Schlüter, ACMS’ Managing Director, shares his views on why building is never truly climate-neutral and why timber construction must also be subjected to critical scrutiny. At the same time, he also shows how to build in a truly climate-friendly way.

Genuinely climate-neutral buildings are not currently possible

In order to build sustainably, the entire life cycle of a building must be considered instead of looking one-sidedly at the utilization phase, as has been the case so far on the part of the legislation (through EnEV and GEG). In fact, with regard to greenhouse gas emissions, the construction phase is now much more decisive than the operation phase – even calculated over 50 years. ACMS Architects attempted to construct a truly climate-neutral building as part of the DBU's +++ Haus research project. The result: no matter what building materials and energy sources we used, it was simply not possible (without the legally defined calculation tricks).

The limits of wood as a building material

Every material and every building component causes CO2 emissions throughout its life cycle. This also applies to wood. Supposedly climate-friendly, wood as a building material also has critical aspects when looked at more closely. At the moment, we are taking much more of it out of the forests than is actually growing back. In Germany, consumption is so high that it would take three Earths if the rest of the world consumed just as much. The trees usually used for construction, such as spruce, are ready to be felled when they absorb the most CO2. It may therefore make even more sense to leave the trees standing and build with concrete instead, since the trees' lost storage capacity weighs more heavily on the climate than the emissions resulting from cement production.

The situation is even more problematic for hardwoods such as beech, which have to be much older to be ready for felling. At the same time, only 45 percent of them can be used as construction timber. The residual wood can currently only be utilized in ways that again lead to further short-term carbon emissions.

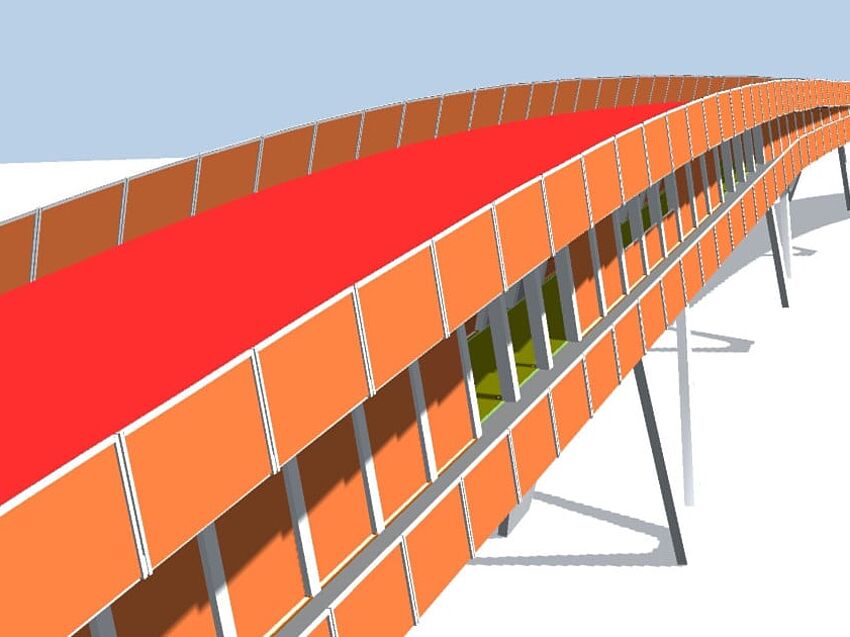

Skeletal load-bearing structures made of reinforced concrete, building envelopes made of wood

Since reinforced concrete is also highly questionable from a climatic point of view, it is important to design structures from it in such a way that the use of the building material is as low (i.e. as lean) as possible. The crux of sustainable building is in itself to avoid building in the first place. However, if new construction is unavoidable, it should in turn be as durable as possible. ACMS Architects therefore advocate minimal skeletal structures that can be used flexibly over a very long period of time. For the building envelope, we rely on wood, but in a very material-saving way. In addition to thinner walls (and thus less material) and a better eco-balance, wood also offers a high quality of construction thanks to prefabrication. This is important because energy-efficient construction is less forgiving of mistakes.

Industrial building systems and prefabricated construction

Further optimization can also be achieved by borrowing from industrial construction systems. For example, architects sometimes use hollow prestressed concrete planks and steel beams in residential construction. This allows large spans and free floor plans to be achieved, as well as a material saving of around 30 percent. In turn, at ACMS we have now optimized the wooden panel elements for the building envelope so that they can be assembled without scaffolding (i.e. even more economically).

A particularly important approach to sustainable building at ACMS Architects lies in the element construction method. This allows maximum flexibility – not only because of the clean prefabrication, but also in order to be able to react flexibly to different requirements with the right system.

BIM and resource-efficient construction

In realizing our vision of sustainable construction, we rely on digital tools – and plan our projects with ALLPLAN. The Campus RO in Rosenheim, for example, was even carried out as a BIM showcase project completely in OPEN BIM with all participants, from planning to execution. The detailed database that was created can, among other things, contribute to clean and resource-saving deconstruction (another advantage of the element-based construction method).

With regard to BIM and the associated software, I would like to see even greater integration of the topics of resource-conserving construction. In the case of the RO campus, for example, six different system variants had to be compared to find the best solution that balanced the conflicting factors of ecological sustainability and a limited budget. For a practicable life cycle assessment and rapid comparison of variants, as in this case, the required information should ideally already be available on the software side.