30 years after its decommissioning, the Altglienicker Bridge in Berlin will finally receive a new replacement structure. The engineers from AFRY who are responsible for the design voluntarily planned the project with BIM.

The Altglienicker Bridge – which was built in 1906, rebuilt in 1950, and runs between Adlershof and Altglienicke across Berlin’s Teltow Canal – has been closed since 1995. Since then, the structure has merely served as a conduit from one bank to the other, while a makeshift bridge handles traffic in its place. However, since the latter will reach its planned service life of 30 years in 2025, it is time for a real replacement of the Altglienicker Bridge. The bridge and the roadworks are being planned by AFRY Germany. The curious thing is that the planning is being carried out using the BIM method, without the client – the Wasserstraßen-Neubauamt Berlin – having requested it.

Steel composite truss with double curvature

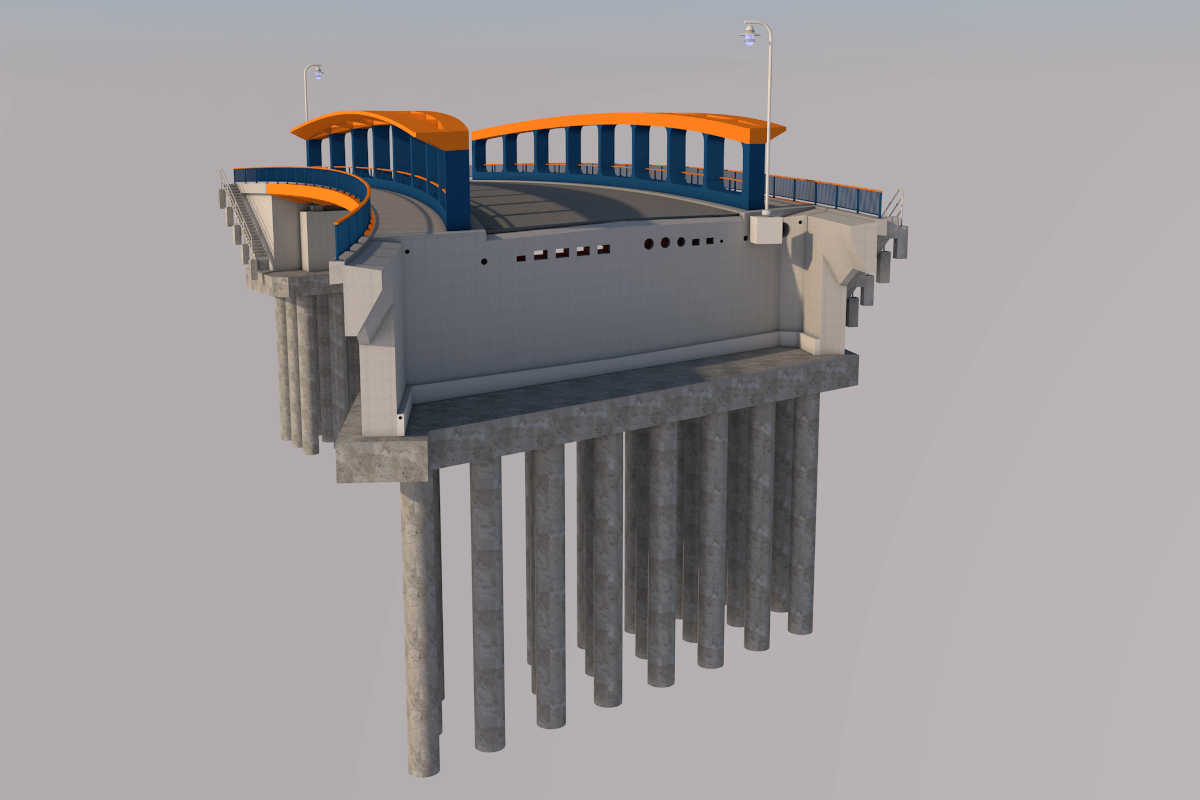

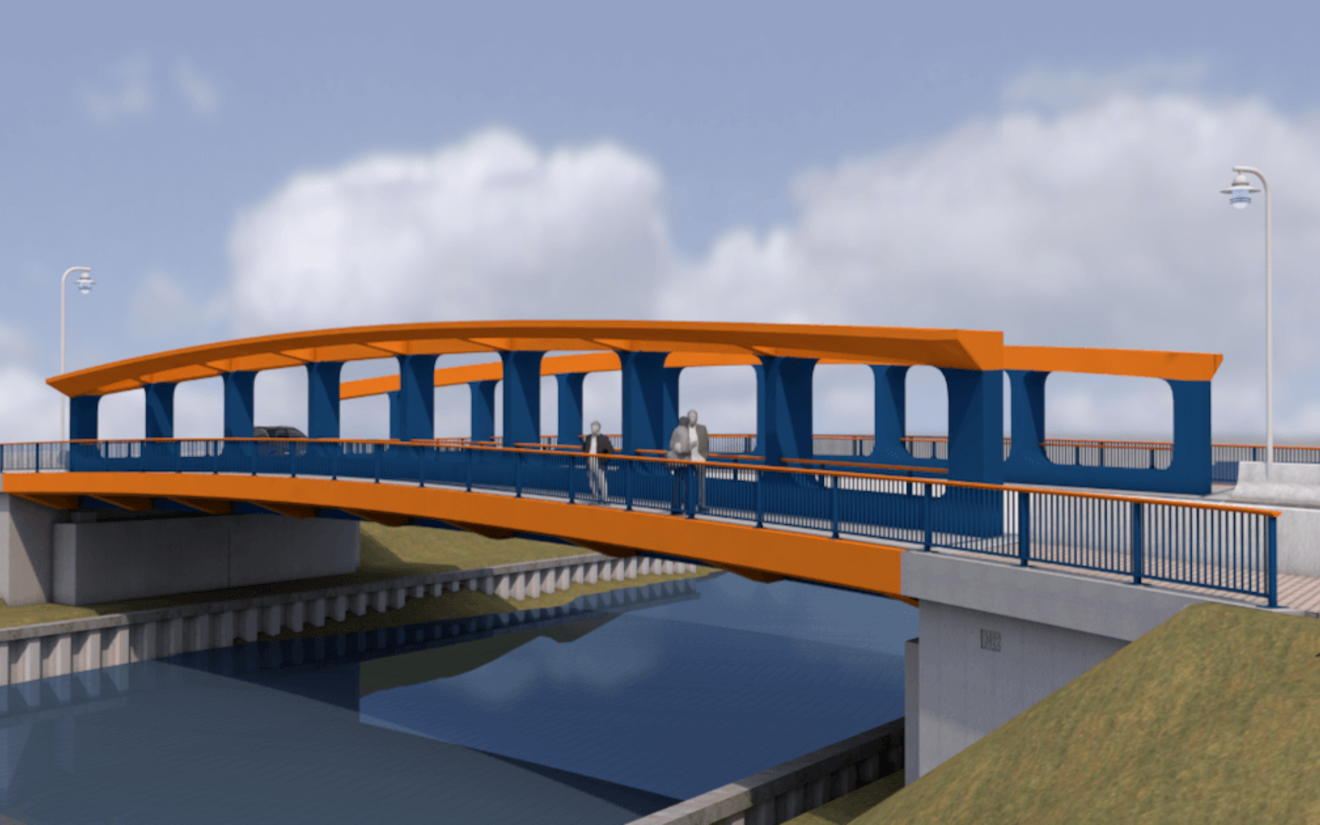

The selected bridge design is a steel composite truss with a clear width of 36 meters and a single-span girder with a span of about 41 meters. Torsional stress is generated by a double curvature in gradient and position. The special curved shape between the sidewalk and the road results in optimum load transfer with the smallest possible dimensions. A small cross girder span, in turn, allows a low overall height, which is appropriate for the narrowness in the waterway area and saves material. Stability is provided by a lateral arch transition that absorbs the transverse bending and, on top of that, serves as a lighting strip. A deep foundation saves an expensive watertight excavation in the abutment area. The bridge itself is assembled by floating it in place by crane.

Increased efficiency and quality through BIM

AFRY made a conscious decision to design with BIM without any contractual obligation – for good reason. “In our day-to-day work, we see a significant increase in efficiency and quality through using BIM in various subareas,” explains Paul-Christian Max, BIM Implementation Manager, Project Manager, and BIM Coordinator at AFRY Deutschland GmbH. “In addition, model-based work leads to a better understanding of the respective situation – both for us and for our project partners.”

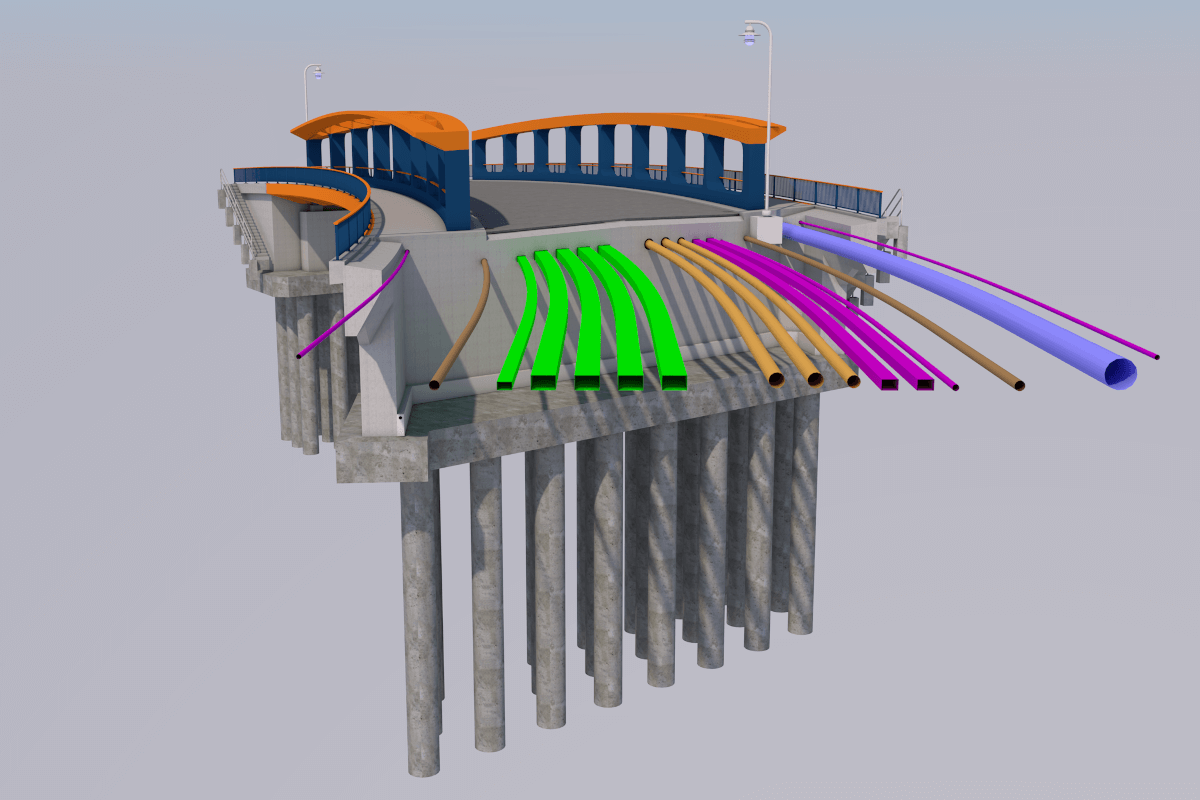

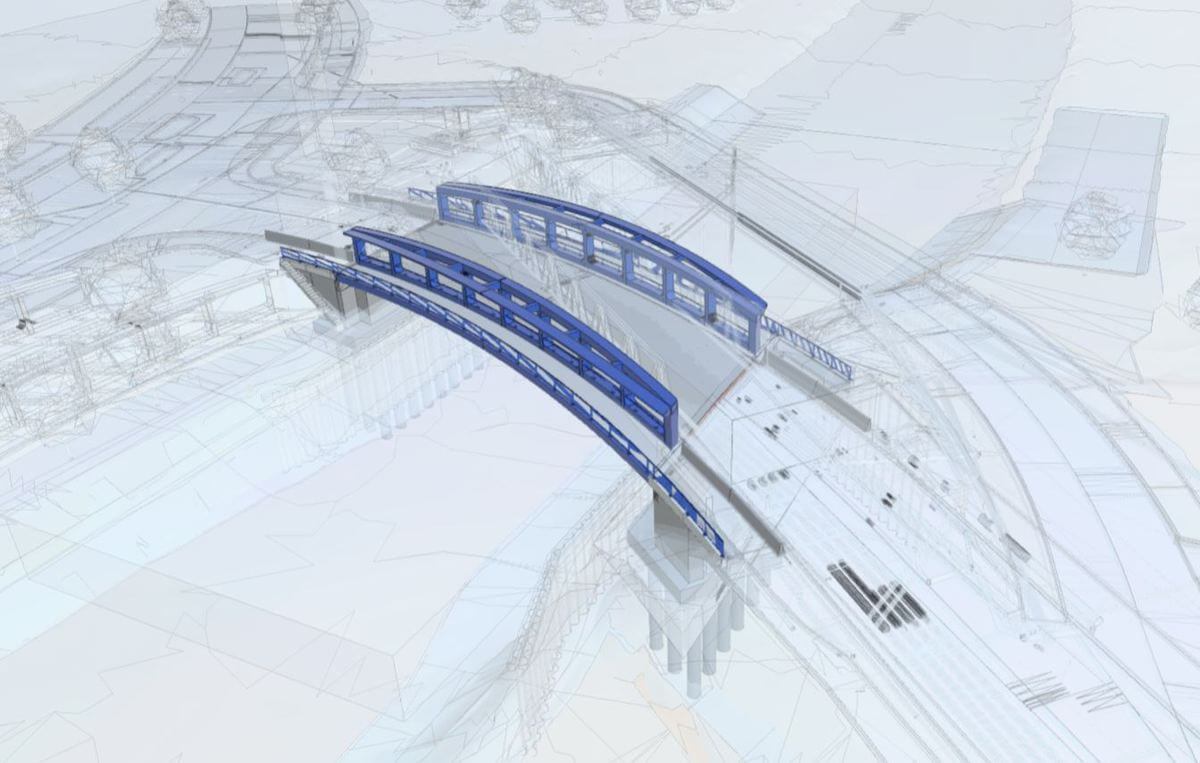

For the Altglienicker Bridge project, the engineers relied on a software package comprising of ALLPLAN Bridge, ALLPLAN, and ALLPLAN Bimplus. First, the data for the planned road route was uploaded in XML format to the BIM platform Bimplus, from which it was then imported into ALLPLAN Bridge. Based on the route, the team was able to model the previously developed bridge variant using axis and cross-section definitions in the bridge construction software. Further design, such as extension details, plan derivations, etc., was then carried out in ALLPLAN Engineering. In addition, the engineers provided the various components with attributes such as reconstruction category and trade assignment, as well as relevant values for quantity takeoff. Due to an internal open BIM philosophy, data was exchanged and coordinated internally and externally in IFC format.

Working with BIM paid off

Working with BIM paid off. The attributed IFCs enabled automated – and thus extremely time-saving – calculations of the construction sequence (4D) and construction costs (5D). Thanks to attributes such as trade assignment, it was also possible to optimally coordinate the trades. In addition, rule-based and visual collision checks were an important contributor to the very high design quality. Model-based issue-tracking improved communication between project participants. The model added further value through deriving the plan directly from the model and, last but not least, through the improved visualization of the bridge. This enabled a better understanding of the double-curved construction and thus contributed significantly to a higher detail quality.