To implement the urgently needed replacement of the Aabach Bridge near Uster in Switzerland as quickly as possible, the project was planned and approved on an expedited basis – thanks in part to ALLPLAN.

When the 28-meter-long Aabach Bridge on Seestrasse between Uster and Greifensee (Switzerland) was inspected in August 2022, the verdict was quickly made: the bridge had to be partially closed. This immediate, strict measure was due to chloride contamination and reinforcement corrosion in the bridge’s substructure, as well as structural deficiencies in the bridge deck. As a result of these findings, traffic over the bridge was significantly restricted (limited to one lane, no heavy vehicles). An immediate replacement was also necessary to restore the critical connection along the Seestrasse as soon as possible. With the use of ALLPLAN, the planning and approval process was completed within just six months.

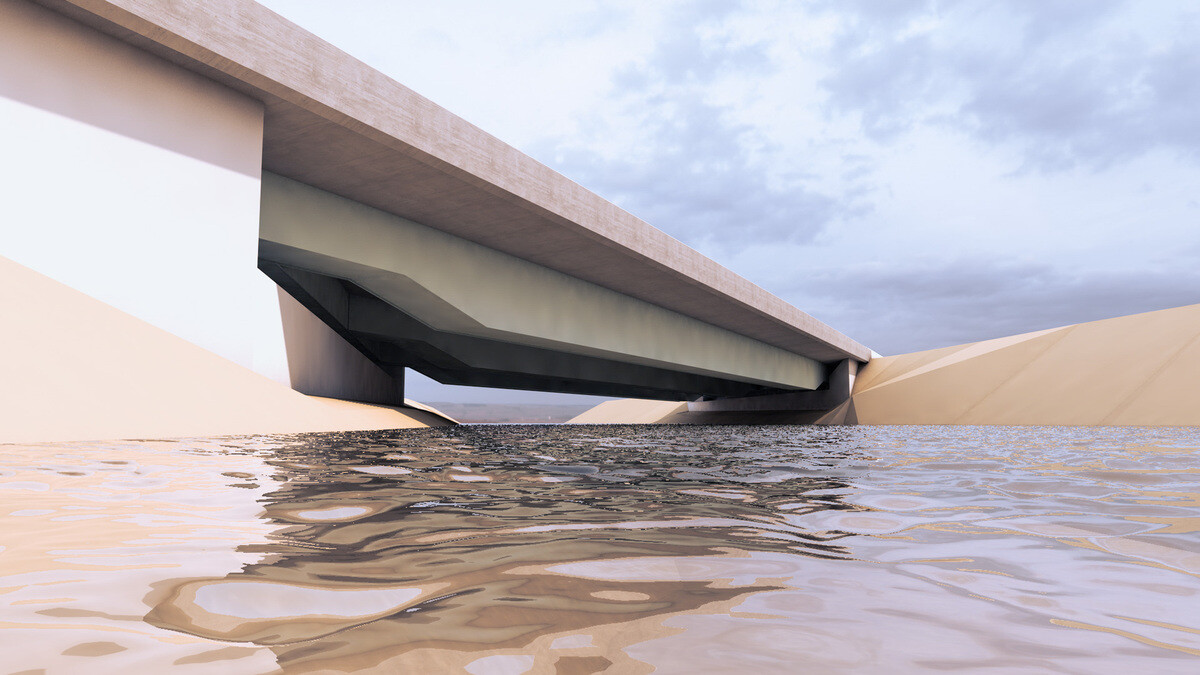

Composite Steel Bridge with Corten Steel Box Girders

The planning of the new bridge was entrusted to ASCHWANDEN & PARTNER Engineers and Planners ETH/SIA AG (ASCHWANDEN & PARTNER) from Rüti. Out of three developed options, the civil engineering office ultimately chose (on the recommendation of ASCHWANDEN & PARTNER) a composite steel bridge with box girders made of Corten steel. This much lighter construction enabled, among other things, an optimized construction process and the preservation of the existing abutments. However, due to wear and tear, the abutments needed to be rehabilitated first. After the demolition of the old bridge deck, the concrete had to be removed down to the second reinforcement layer and then reprofiled.

Precision in Combining Old and New

To ensure the new structure fit perfectly with the existing abutments, the utmost precision was required in both the planning and the prefabrication of the steel and concrete components. The concrete slab construction was divided into two stages. Since the steel girders could not support the weight of the fresh concrete without significant deflection, the first lower section of the slab was manufactured on the prefabrication site. After this section was lifted into place with the steel girders using a crawler crane, it served as the formwork for the rest of the bridge slab in the next step. Additionally, the sealing and surfacing were completed, and the fittings installed.

As-Built Model and New Construction Modeling in ALLPLAN

The planning in ALLPLAN included the creation of an accurate as-built model based on survey data and as-built plans, as well as an exact model of the new construction. The as-built model was initially created through free modeling and then aligned with the survey data. This model was instrumental in successfully integrating the old and new elements and was also used to derive quantities and dimensions for the demolition work.

For the new construction modeling, various modules were creatively employed. For example, the steel structure model was created using architectural components, where a wall with a thickness of 33mm formed a plate of the girder. This plate was connected to reference planes at the top and bottom edges of the bridge (defined by the future road project and flood levels), allowing height adjustments to be easily made by modifying these planes. Other architectural components served as stiffening plates (20mm walls with windows as openings) and shear studs (95mm columns). The reinforcement was initially roughly modeled and then further detailed in the derived 2D plan.