When it comes to 3D printed construction materials, concrete seems an obvious choice. However, architects are constantly pushing the boundaries of what can be achieved, such as using steel to create a 3D printed bridge. For example, the American Institute of Steel Construction (AISC)1 in Chicago, USA recently awarded their prestigious 2021 Forge Prize2 to a unique 3D printed steel bridge concept developed by Hunter Ruthrauff of San Diego-based T.Y. Lin International Group3. This unconventional design, although conceptual, demonstrates the possibilities that 3D printing with steel can offer.

A Design Inspired by its Surroundings

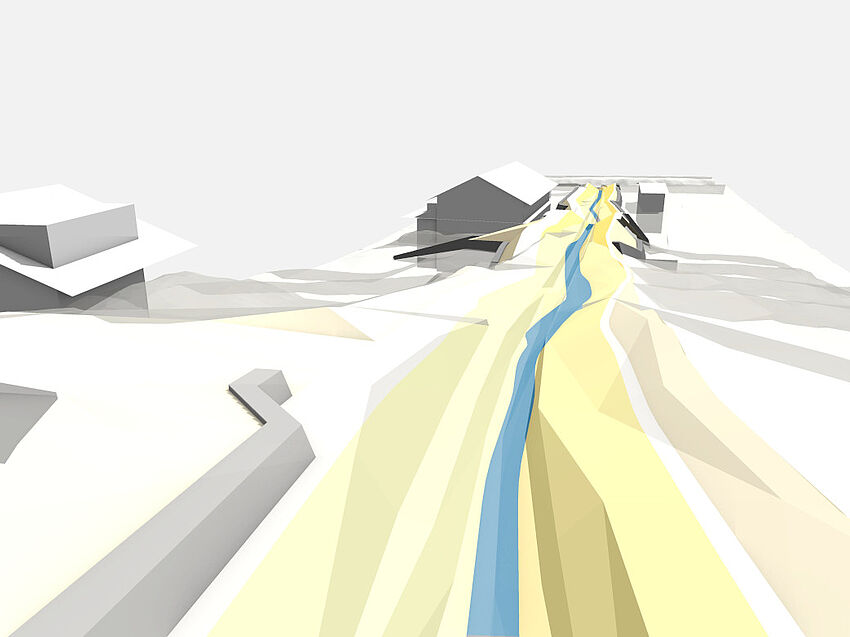

The winning design features a pedestrian footbridge which crosses the Florida Canyon outside of San Diego, California, located on the eastern boundary of The Prado, the city’s cultural area. The proposed bridge would create an east-west connection that is currently lacking in the locale, helping to encourage development in the area.

Inspiration for the design was taken from the nearby Cabrillo Bridge, which is an arched cast in-situ concrete bridge. To create these grand arches, thousands of formwork boards were used during construction, which was something the architect wanted to avoid. However, the below-deck structure of the Cabrillo Bridge lends itself to creating excellent views of the area, which is imitated in the proposed design. The fluidity of the local flora – such as cacti and fig trees – and eroded canyon walls, as well as the almost cellular network of the canyon were also an inspiration for the organic forms of the bridge.

The unique surface was inspired by the Spanish influence on local architecture, which features large amounts of relief work. The articulated surface of the bridge is a modern take on this, which was initially modeled using a water flow analysis. The lines of the flowing water were used to determine where the articulations should be placed. Small, spherical luminaires are also incorporated onto the surface of the bridge so that they mirror the night sky when looking up at the bridge from within the canyon.

A Fluid Footbridge

The bridge begins with a large plaza, before the bridge deck expands and contracts along the length. There are four apertures along the deck, which allows pedestrians to maintain a visual connection to the canyon below. Each aperture also has a hammock that allows pedestrians a unique experience if they are brave enough to venture onto them. The railing system uses 3D printed stainless steel columns to which glass panels are attached so as not to block the views of the local area.

The bridge is made up of three 250-foot spans, with the under-bridge structure resembling a cellular network. To model this form, mesh relaxation was used. Simple structural members were initially used for the design, which then were relaxed into the final organic forms by introducing tension into the system to smooth out the shapes.

Why 3D Print a Bridge?

Creating splines and double curved shapes in steel was a challenge that could only be overcome using 3D printing. Using wire arc additive manufacturing – first invented by MX3D4 in the Netherlands – complex shapes can be achieved using steel. The bridge is designed to be printed in smaller components and then pieced together by lifting the component into position and bolting it to adjacent components. Each component has internal stiffeners, as well as a porthole that allows access inside to the bolts. The components are made up of a carbon steel inner core with a stainless steel outer layer, which saves money in comparison to having the entire structure made of stainless steel. With 3D printing, the required accuracy to fabricate these layers of materials can be achieved.

To construct the bridge, balanced cantilever segmental construction would be used, where the foundations and abutments are first constructed, followed by the piers which are supported by cable stays. This eliminates any falsework requirements. Then arch segments are added until the central and outer keystone pieces are placed, which stabilizes the bridge. The stay towers can then be removed so that the spandrels and deck segments can be added.

The Benefits of 3D Printed Steel

This method has advantages in that the designer is delivering a shop drawing direct to the fabricators, making the design and construction process more efficient. In addition, no geometry needed to be defined in 2D which saved time. The double curvature is well suited for 3D printing in steel, particularly in comparison to 3D printed concrete which would still require tendons and reinforcement to be incorporated somehow. The speed of the construction is also only limited by the amount of 3D printing robots that are available – more robots can fabricate a design quite quickly. A further advantage of 3D printing is that this would also help reduce the local disruption during construction, both to nearby residents as well as to the canyon ecosystem.

The architect, Mr. Ruthrauff, wanted to push the boundaries of steel construction – and that aim has been well and truly achieved with this pioneering design.

Source:

1 https://www.aisc.org/

2https://www.aisc.org/pressreleases/press-releases/innovative-3d-printed-steel-bridge-concept-wins-2021-forge-prize/

3https://www.tylin.com/en/news/article/421

4https://mx3d.com/