ALLPLAN 2025-1: Smarter Workflows and Stronger Collaboration

Guest Post by Gregor Štrekelj, Product Manager for Infrastructure at ALLPLAN

Building Information Modeling (BIM) is becoming more widely used for infrastructure, including 3D bridge modeling. Current modeling techniques are particularly suited to bridges whose geometry is governed by the bridge axis or alignment. However, precast girder bridges are different because their geometry is only indirectly governed by the axis, making them trickier to model. Yet, with these three tools, these challenges can be overcome to make modeling precast girder bridges much easier and more efficient.

Why are Precast Girder Bridges Unique?

The size and type of precast girder bridges may vary, but their component geometry is normally the same. Because girders are straight, their geometry is not directly impacted by the road or bridge axis. This is also the case with respect to their final position on the bridge, which is dictated by the geometry of the supporting substructure. For these reasons, a different approach is required when modeling precast girder bridges.

The updated modeling workflow in the latest version of ALLPLAN Bridge – a complete, integrated BIM solution for bridges – includes new features that enable precast girder bridges to be created with ease. With just one bridge model, an entire BIM-supported bridge design process can be carried out from within this parametric design solution, with tools developed specifically for precast girder bridges.

1. Rapid Precast Girder Creation with Link Girder and Modular Modeling

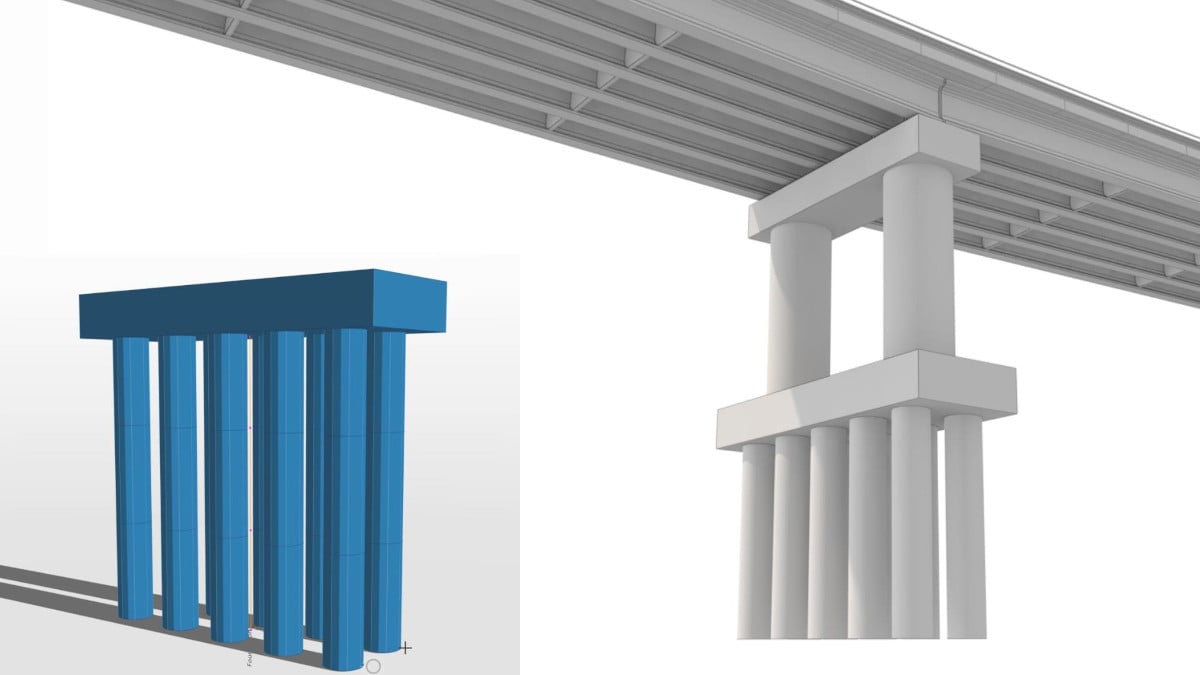

For precast girder bridges, a similar modeling approach to the conventional process is used at first. The bridge axes need to be created or imported, and the cross-sectional geometry either designed or taken from a template. Then, the substructure – with or without foundations – can be generated, and the precast girders positioned on top.

The new Link Girder element makes modeling precast girders much faster. It uses a parametric, linear, 3D element between two 3D points to define the virtual and local axis. It can then be used to calculate geometry, model tendons, defining the construction sequence, and even detailing, rebar modeling, and drawing production.

The modular modeling feature helps address the reuse of girder shapes and lengths efficiently. Templates are created for link girder elements or pier elements, and are used in the 3D model as many times as necessary simply by dragging and dropping them in. The length can be either specified directly or a virtual length is used until the girder is positioned on the substructure. Where the girder section varies, fixed stations indicate where the cross-section change happens without affecting the ability to correctly adjust the girder. This way, all the girders can be generated rapidly, saving considerable time.

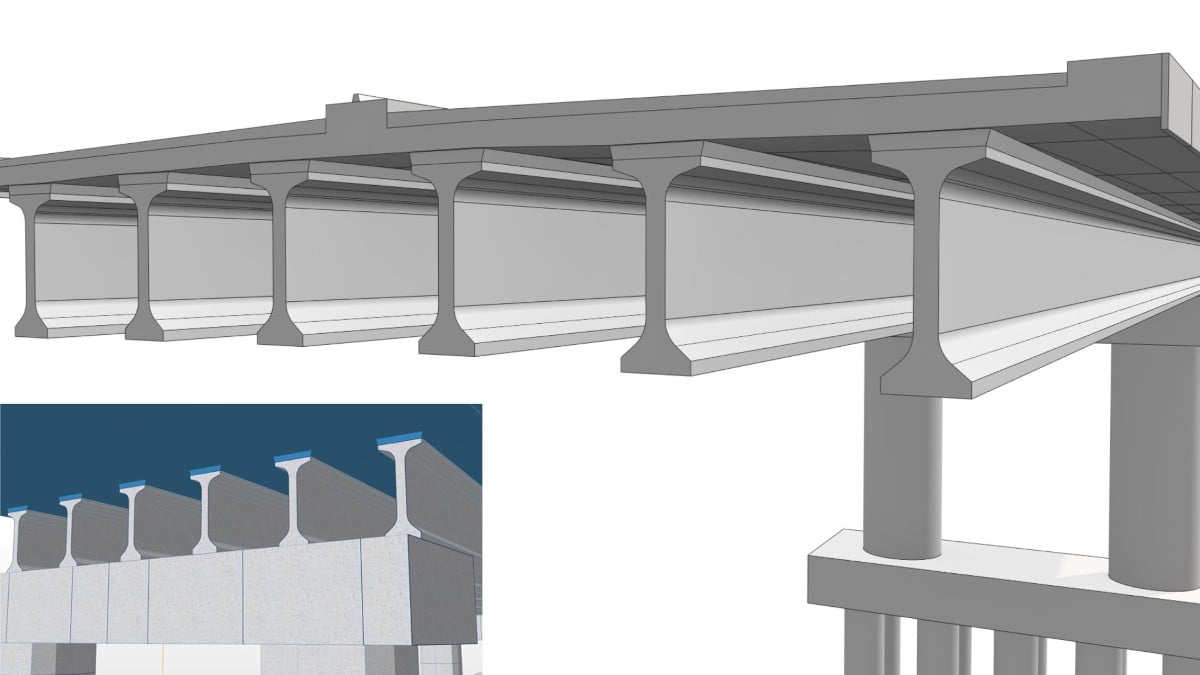

2. Easy Haunch Definition with Boolean Operations

After creating the bridge deck, there will be a gap between the girders and plate. Filling this requires a haunch, but the 3D geometry for this is complex and difficult to model accurately. ALLPLAN Bridge solves this problem by using 3D Boolean operations to create the haunch quickly and easily. By creating a cross-section of the haunch, the 3D form is automatically calculated and generated based on the other bridge parameters. The user just needs to ensure that the cross-section of the haunch intersects the deck plate and the software will automatically merge them together.

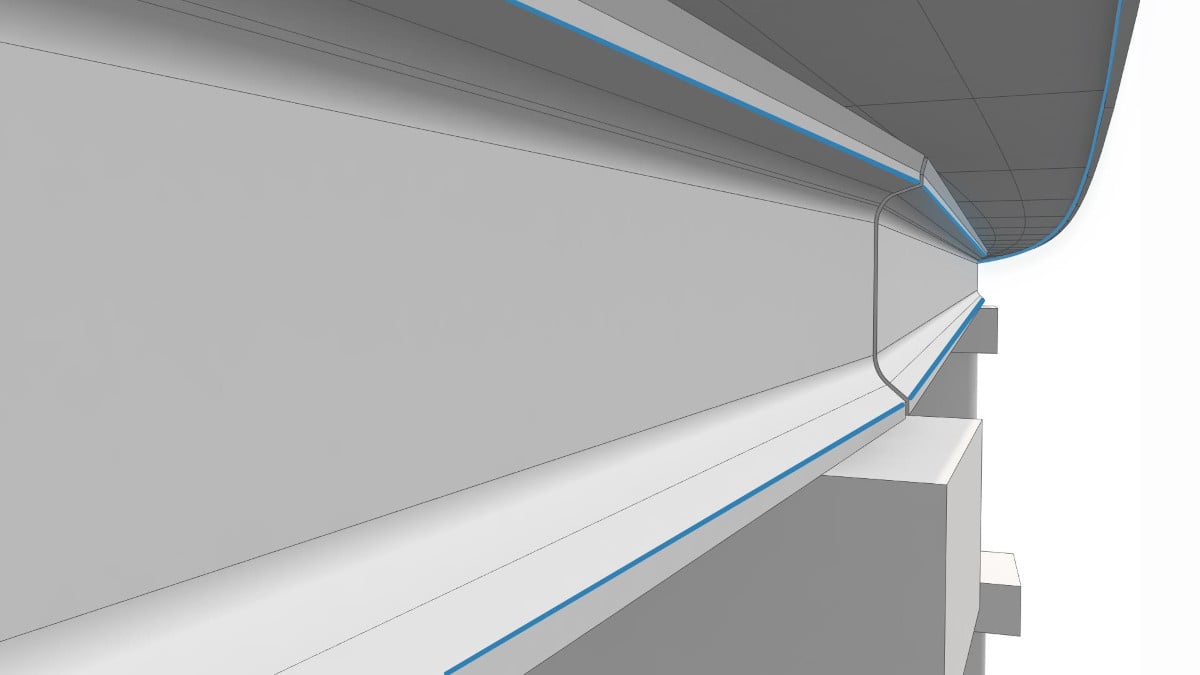

3. Quick Girder Reinforcement Modeling Using Templates

Templates can also be prepared for the girder reinforcement using a PythonPart. The advantage of this method is that it can be used multiple times in the same project or across projects, saving time. The parametric template can be linked with the girder model’s parameters, so any changes to the girder are reflected in the reinforcement – for example, lengthening or widening the girder automatically updates the reinforcement to match. For any further changes, the parameters – such as bar size, shape, or spacing – can be changed and the model will update automatically.

An Accelerated Design Process

This improved modeling approach for precast girder bridges significantly accelerates the design process. The BIM process can also be completely supported with the integration and synchronization offered by ALLPLAN’s cloud-based BIM platform, Bimplus, which offers optimized BIM workflows. Combined with ALLPLAN’s precast expertise through ALLPLAN Precast solutions – including detailing and manufacturing work preparation – a complete design, manufacture, and build approach can be supported. As prefabricated girder bridges are one of the most common bridge types used globally, the time – and therefore cost – savings can be significant.

Learn more and watch the presentation now.

Gregor Štrekelj,

Product Manager

for Infrastructure